Abstract

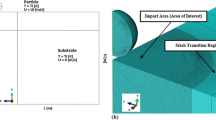

Cold spraying is receiving increasing attention as a method for metallizing polymer surfaces. Although metallic coatings on polymer surfaces have been successfully prepared in several studies, these are currently only in the experimental stages. In this study, the impact behaviour of copper particles deposited on polyether ether ketone (PEEK) substrates by cold spraying was investigated, and the deposition mechanism of the coatings was elucidated based on numerical simulations. Computational fluid dynamics simulations were used to determine the impact velocity of the particles, initial temperature of the particles, and surface temperature of the substrates. An Eulerian–Lagrange three-dimensional finite element model was developed to simulate the impact behaviour of single and multiple copper particles on the PEEK substrate. The numerical simulation results showed good agreement with the experimental data reported in the literature. This indicates that the thermal softening and melting of the material provide good conditions for mechanical interlocking of the particles with the substrate. Based on the results, the effects of particle velocity, particle temperature, and substrate temperature on the cold spray deposition behaviour of copper particles on PEEK substrates are discussed.

Similar content being viewed by others

References

G. Zhang, H. Yu, C. Zhang, H. Liao and C. Coddet, Temperature Dependence of the Tribological Mechanisms of Amorphous PEEK (Polyetheretherketone) under Dry Sliding Conditions, Acta Mater., 2008, 56, p 2182–2190.

X. Chen, Y. Su, D. Reay, and S. Riffat, Recent Research Developments in Polymer Heat Exchangers – A Review, Renew. Sustain. Energy Rev. 2016, 60, p 1367–1386. https://doi.org/10.1016/j.rser.2016.03.024

S. Najeeb, M.S. Zafar, Z. Khurshid and F. Siddiqui, Applications of Polyetheretherketone (PEEK) in Oral Implantology and Prosthodontics, J. Prosthodont. Res., 2016, 60(1), p 12–19. https://doi.org/10.1016/j.jpor.2015.10.001

J. Zhang, W. Tian, J. Chen, J. Yu, J. Zhang and J. Chen, The Application of Polyetheretherketone (PEEK) Implants in Cranioplasty, Brain Res. Bull., 2019, 153, p 143–149. https://doi.org/10.1016/j.brainresbull.2019.08.010

V. Siegel and J. Kotal, Preparation of Thin Metal Layers on Polymers, Prep. Thin Met. Layers Polym., 2007, 47, p 339.

T. Duguet, F. Senocq, L. Laffont and C. Vahlas, Metallization of Polymer Composites by Metalorganic Chemical Vapor Deposition of Cu: Surface Functionalization Driven Films Characteristics, Surf. Coatings Technol., 2013, 230, p 254–259. https://doi.org/10.1016/j.surfcoat.2013.06.065

R. Gonzalez, H. Ashrafizadeh, A. Lopera, P. Mertiny, and A. McDonald, A Review of Thermal Spray Metallization of Polymer-Based Structures, J. Therm. Spray Technol. 2016, 25, p 897–919. https://doi.org/10.1007/s11666-016-0415-7

A. Pascual, M. Toma, P. Tsotra and M.C. Grob, On the Stability of PEEK for Short Processing Cycles at High Temperatures and Oxygen-Containing Atmosphere, Polym. Degrad. Stab., 2019, 165, p 161–169. https://doi.org/10.1016/j.polymdegradstab.2019.04.025

M. Gardon, A. Latorre, M. Torrell, S. Dosta, J. Fernández and J.M. Guilemany, Cold Gas Spray Titanium Coatings onto a Biocompatible Polymer, Mater. Lett., 2013, 106, p 97–99. https://doi.org/10.1016/j.matlet.2013.04.115

E. Aubignat, R. Kromer, S. Costil, V. Gillet, and C. Langlade, Manufacturing of Copper Coatings on Aluminum and Organic Substrates By Low-Pressure Cold Spray. In: Proceedings of the 30th International Conference on Surf. Modif. Technol. Milan (2016)

H. Che, X. Chu, P. Vo and S. Yue, Cold Spray of Mixed Metal Powders on Carbon Fibre Reinforced Polymers, Surf. Coatings Technol., 2017, 329, p 232–243. https://doi.org/10.1016/j.surfcoat.2017.09.052

A. Ganesan, M. Yamada and M. Fukumoto, Cold Spray Coating Deposition Mechanism on the Thermoplastic and Thermosetting Polymer Substrates, J. Therm. Spray Technol., 2013, 22(8), p 1275–1282. https://doi.org/10.1007/s11666-013-9984-x

A. Ganesan, J. Affi, M. Yamada and M. Fukumoto, Bonding Behavior Studies of Cold Sprayed Copper Coating on the PVC Polymer Substrate, Surf. Coatings Technol., 2012, 207, p 262–269. https://doi.org/10.1016/j.surfcoat.2012.06.086

X.L. Zhou, A.F. Chen, J.C. Liu, X.K. Wu and J.S. Zhang, Preparation of Metallic Coatings on Polymer Substrate Composites by Cold Spray, Surf. Coatings Technol., 2011, 206(1), p 132–136. https://doi.org/10.1016/j.surfcoat.2011.07.005

P.C. King, A.J. Poole, S. Horne, R. de Nys, S. Gulizia and M.Z. Jahedi, Embedment of Copper Particles into Polymers by Cold Spray, Surf. Coatings Technol., 2013, 216, p 60–67. https://doi.org/10.1016/j.surfcoat.2012.11.023

M.J. Vucko, P.C. King, A.J. Poole, C. Carl, M.Z. Jahedi and R. de Nys, Cold Spray Metal Embedment: An Innovative Antifouling Technology Biofouling, Taylor Francis, 2012, 28(3), p 239–248. https://doi.org/10.1080/08927014.2012.670849

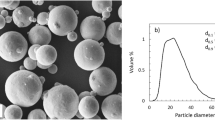

C. Chen, X. Xie, Y. Xie, X. Yan, C. Huang, S. Deng, Z. Ren and H. Liao, Metallization of Polyether Ether Ketone (PEEK) by Copper Coating via Cold Spray, Surf. Coatings Technol., 2018, 342, p 209–219. https://doi.org/10.1016/j.surfcoat.2018.02.087

L.L. Koithara, R.N. Raoelison, S. Costil and X. Xie, High Deposition Efficiency and Delamination Issues during High-Pressure Cold Spraying Metallization of PEEK Using Spherical Copper Powders, Int. J. Adv. Manuf. Technol., 2020, 107(11), p 4427–4436. https://doi.org/10.1007/s00170-020-05349-z

H. Che, X. Chu, P. Vo and S. Yue, Metallization of Various Polymers by Cold Spray, J. Therm. Spray Technol., 2018, 27(1), p 169–178. https://doi.org/10.1007/s11666-017-0663-1

H. Che, P. Vo and S. Yue, Investigation of Cold Spray on Polymers by Single Particle Impact Experiments, J. Therm. Spray Technol., 2019, 28(1), p 135–143. https://doi.org/10.1007/s11666-018-0801-4

H. Assadi, F. Gärtner, T. Stoltenhoff and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379–4394. https://doi.org/10.1016/S1359-6454(03)00274-X

M. Grujicic, C.L. Zhao, W.S. DeRosset and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681–688. https://doi.org/10.1016/j.matdes.2004.03.008

R. Lupoi and W. O’Neill, Deposition of Metallic Coatings on Polymer Surfaces Using Cold Spray, Surf. Coatings Technol., 2010, 205(7), p 2167–2173. https://doi.org/10.1016/j.surfcoat.2010.08.128

ABAQUS, Academic Research User Manual Guide (In Release 6.14)

R. Chakrabarty and J. Song, Effect of Impact Angle on Ceramic Deposition Behavior in Composite Cold Spray: A Finite-Element Study, J. Therm. Spray Technol., 2017, 26(7), p 1434–1444. https://doi.org/10.1007/s11666-017-0604-z

R. Chakrabarty and J. Song, Numerical Simulations of Ceramic Deposition and Retention in Metal-Ceramic Composite Cold Spray, Surf. Coatings Technol., 2020, 385, 125324. https://doi.org/10.1016/j.surfcoat.2019.125324

E. Lin, Q. Chen, O.C. Ozdemir, V.K. Champagne and S. Müftü, Effects of Interface Bonding on the Residual Stresses in Cold-Sprayed Al-6061: A Numerical Investigation, J. Therm. Spray Technol., 2019, 28, p 472–483. https://doi.org/10.1007/s11666-019-00827-7

G.R. Johnson and W.H. Cook, A Constitutive Model and Data from Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings 7th International Symposium on Ballistics (1983), pp. 541–547

D. Rittel, On the Conversion of Plastic Work to Heat during High Strain Rate Deformation of Glassy Polymers, Mech. Mater., 1999, 31(2), p 131–139. https://doi.org/10.1016/S0167-6636(98)00063-5

T. Bjerke, Z. Li and J. Lambros, Role of Plasticity in Heat Generation during High Rate Deformation and Fracture of Polycarbonate, Int. J. Plast., 2002, 18(4), p 549–567. https://doi.org/10.1016/S0749-6419(01)00009-2

M. Nasraoui, P. Forquin, L. Siad and A. Rusinek, Influence of Strain Rate, Temperature and Adiabatic Heating on the Mechanical Behaviour of Poly-Methyl-Methacrylate: Experimental and Modelling Analyses, Mater. Des., 2012, 37, p 500–509. https://doi.org/10.1016/j.matdes.2011.11.032

P.J. Rae, E.N. Brown, and E.B. Orler, The Mechanical Properties of Poly(Ether-Ether-Ketone) (PEEK) with Emphasis on the Large Compressive Strain Response, Polymer., 2007, 48(2), 598–615.

H. Pouriayevali, S. Arabnejad, Y.B. Guo and V.P.W. Shim, A Constitutive Description of the Rate-Sensitive Response of Semi-Crystalline Polymers, Int. J. Impact Eng., 2013, 62, p 35–47. https://doi.org/10.1016/j.ijimpeng.2013.05.002

D. Garcia-Gonzalez, A. Rusinek, T. Jankowiak and A. Arias, Mechanical Impact Behavior of Polyether–Ether–Ketone (PEEK), Compos. Struct., 2015, 124, p 88–99. https://doi.org/10.1016/j.compstruct.2014.12.061

F. Chen, H. Ou, B. Lu and H. Long, A Constitutive Model of Polyether-Ether-Ketone (PEEK), J. Mech. Behav. Biomed. Mater., 2016, 53, p 427–433. https://doi.org/10.1016/j.jmbbm.2015.08.037

L. Ming and O. Pantalé, An Efficient and Robust VUMAT Implementation of Elastoplastic Constitutive Laws in Abaqus/Explicit Finite Element Code, Mech. Ind., 2018, 19(3), p 15. https://doi.org/10.1051/meca/2018021

D.L. Baragar, The High Temperature and High Strain-Rate Behaviour of a Plain Carbon and an HSLA Steel, J. Mech. Work. Technol., 1987, 14(3), p 295–307.

B.H. Lim, H. Liao and W.W. Chen, Effects of Constant Engineering and True Strain Rates on the Mechanical Behavior of 304 Stainless Steel, J. Dyn. Behav. Mater., 2017, 3(1), p 1–7.

VICTREX high performance paek polymers, VICTREX PEEK properties guide (2021). https://www.victrex.com. Accessed 6 March 2003

B. Yildirim, S. Muftu and A. Gouldstone, Modeling of High Velocity Impact of Spherical Particles, Wear, 2011, 270(9), p 703–713. https://doi.org/10.1016/j.wear.2011.02.003

J. Vlcek, L. Gimeno, H. Huber and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold-Spray Process, J. Therm. Spray Technol., 2005, 14(1), p 125–133. https://doi.org/10.1361/10599630522738

E.A. Flores-Johnson, M. Saleh and L. Edwards, Ballistic Performance of Multi-Layered Metallic Plates Impacted by a 7.62-Mm APM2 Projectile, Int. J. Impact Eng., 2011, 38(12), p 1022–1032. https://doi.org/10.1016/j.ijimpeng.2011.08.005

Y. Xie, S. Yin, C. Chen, M.-P. Planche, H. Liao and R. Lupoi, New Insights into the Coating/Substrate Interfacial Bonding Mechanism in Cold Spray, Scr. Mater., 2016, 125, p 1–4. https://doi.org/10.1016/j.scriptamat.2016.07.024

H. Zhou, C. Li, C. Bennett, H. Tanvir and C. Li, Numerical Analysis of Deformation Behavior and Interface Bonding of Ti6Al4V Particle After Subsequent Impact During Cold Spraying, J. Therm. Spray Technol., 2021, 30(4), p 1093–1106. https://doi.org/10.1007/s11666-021-01188-w

G. Bae, Y. Xiong, S. Kumar, K. Kang and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858–4868. https://doi.org/10.1016/j.actamat.2008.06.003

R. Huang and H. Fukanuma, Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits, J. Therm. Spray Technol., 2012, 21(3), p 541–549. https://doi.org/10.1007/s11666-011-9707-0

Y. Li, X. Wang, S. Yin and S. Xu, Influence of Particle Initial Temperature on High Velocity Impact Process in Cold Spraying, Procedia Environ. Sci., 2012, 12, p 298–304. https://doi.org/10.1016/j.proenv.2012.01.281

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51775427), all of the authors are grateful to the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, W., Zhang, J., Li, Y. et al. Numerical Simulation of the Cold Spray Deposition of Copper Particles on Polyether Ether Ketone (PEEK) Substrate. J Therm Spray Tech 30, 1792–1809 (2021). https://doi.org/10.1007/s11666-021-01254-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01254-3