Abstract

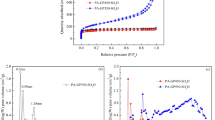

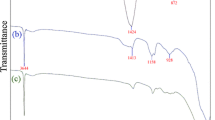

This study demonstrated the performance of the sugarcane bagasse ash (SCBA) impregnated with calcium oxide (CaO) as a novel heterogeneous basic catalyst in biodiesel production. The SCBA was prepared by calcination for 2 h at 500 to 800 °C and impregnated with CaO loadings (10 to 40 wt.%). The prepared SCBA/CaO catalyst was characterized using Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), X-ray diffraction (XRD), temperature programmed desorption of carbon dioxide (TPD-CO2), thermal gravimetric analysis (TGA), X-ray fluorescence (XRF) and Brunauer-Emmett-Teller (BET) surface characteristics. A series of transesterification reactions were conducted to evaluate the performance of the catalysts. As a result, highest FAME yield of 93.8% was obtained by using SCBA600°C CaO(40%) catalyst at 20:1 methanol-to-oil molar ratio, reaction temperature of 65 °C, with 6 wt.% catalyst in 3 h. Besides, the catalyst can be reused up to 5 reaction cycles with biodiesel yield of 93.0% and 70.3% at first and fifth cycles, respectively. In this work, it was found that the natural SiO2 in the SCBA has a significant role to enhance the catalytic performance and reduce the catalyst’s deactivation drawback by minimizing the leaching of active sites.

Similar content being viewed by others

References

Atadashi IM, Aroua MK, Aziz A, Sulaiman NMN (2012) Production of biodiesel using high free fatty acid feedstocks. Renew Sust Energ Rev 16(5):3275–3285

Singh V, Sharma YC (2017) Low cost guinea fowl bone derived recyclable heterogeneous catalyst for microwave assisted transesterification of Annona squamosa L. seed oil. Energ Convers Manage 138:627–637

Boey P-L, Pragas G, Hamid MS (2011) Performance of calcium oxide as a heterogeneous catalyst in biodiesel production: a review. Chem Eng J 168(1):15–22

Math MC, Kumar SP, Chetty S (2010) Technologies for biodiesel production from used cooking oil – a review. Energy Sustain Dev 14(4):339–345

Maneerung T, Dai Y, Kawi S, Wang C-H (2016) Sustainable biodiesel production via transesterification of waste cooking oil by using CaO catalysts prepared from chicken manure. Energ Convers Manage 123:487–497

Chen G, Shan R, Li S et al (2015) A biomimetic silicification approach to synthesize CaO-SiO2 catalyst for the transesterification of palm oil into biodiesel. Fuel 153:48–55

Marinković DM, Stanković MV, Veličković AV et al (2016) Calcium oxide as a promising heterogeneous catalyst for biodiesel production: current state and perspectives. Renew Sust Energ Rev 56:1387–1408

Ezzah M, Lokman M, Saiman MI, HinTaufiq-Yap Y (2016) Synthesis and characterization of Fe2O3/CaO derived from Anadara Granosa for methyl ester production. Energ Convers Manage 126:124–131

Sudsakorn K, Saiwuttikul S, Palitsakun S, Seubsai A, Limtrakul J (2017) Biodiesel production from Jatropha Curcas oil using strontium-doped CaO/MgO catalyst. J Environ Chem Eng 5:2845–2852

Kesica Z, Lukic I, Zdujic M, Liu H, Skala D (2012) Mechanochemically synthesized CaO ZnO catalyst for biodiesel production. Procedia Eng 42:1169–1178

Wang S, Shanab R, Wang Y, Lu L, Yuan H (2019) Synthesis of calcium materials in biochar matrix as a highly stable catalyst for biodiesel production. Renew Energy 130:41–49

Chen GY, Shan R, Shi J-F, Yan B-B (2015) Transesterification of palm oil to biodiesel using rice husk ash-based catalysts. Fuel Process Technol 133:8–13

Melero JA, Bautista LF, Iglesias J, Morales G, Sánchez-Vázquez R (2012) Zr-SBA-15 acid catalyst: optimization of the synthesis and reaction conditions for biodiesel production from low-grade oils and fats. Catal Today 195(1):44–53

Lani NS, Ngadi N, Yahya NY, Rahman RA (2017) Synthesis, characterization and performance of silica impregnated calcium oxide as heterogeneous catalyst in biodiesel production. J Clean Prod 146:116–124

Witoon T, Bumrungsalee S, Vathavanichkul P, Palitsakun S, Saisriyoota M, Faungnawakij K (2014) Biodiesel production from transesterification of palm oil with methanol over CaO supported on bimodal meso-macroporous silica catalyst. Bioresour Technol 156:329–333

Falk G, Shinhe GP, Teixeira LB, Moraes EG, Oliveira AN (2019) Synthesis of silica nanoparticles from sugarcane bagasse ash and nano-silicon via magnesiothermic reactions. Ceram Int 45:21618–21624

Faria KC, Holanda JN (2012) Using SEM/EDS for characterization of clay ceramic bearing sugarcane. In: Mendez-Vilas A (ed) Current microscopy contributions to advances in science and technology, vol. 2. Formatex, Badajoz, pp 1085–1092

Souza A, Teixeira S, Santos G, Costa F, Longo E (2011) Reuse of sugarcane bagasse ash (SCBA) to produce ceramic materials. J Environ Manage 92:2774–2780

Mansir N, Yap YH, Rashid U, Lokman MI (2017) Investigation of heterogeneous solid acid catalyst performance on low grade feedstocks for biodiesel production: a review. Energ Convers Manage 141:171–182

Feyzi M, Shahbazi Z (2017) Preparation, kinetic and thermodynamic studies of Al–Sr nanocatalysts for biodiesel production. J Taiwan Inst Chem Eng 71:145–155

Zhao C, Lv P, Yang L, Xing S, Luo W, Wang Z (2018) Biodiesel synthesis over biochar-based catalyst from biomass waste pomelo peel. Energ Convers Manage 160:477–485

Freitas JV, Ruotolo LAM, Farinas CS (2019) Adsorption of inhibitors using a CO2-activated sugarcane bagasse fly ash for improving enzymatic hydrolysis and alcoholic fermentation in biorefineries. Fuel 251:1–9

Hindryawati N, Maniam GP, Karima MR, Chong KF (2014) Transesterification of used cooking oil over alkali metal (Li, Na, K) supported rice husk silica as potential solid base catalyst. JESTECH 17(2):95–103

Lee J, Jong-MinJung J-IO, Ok YS, Lee S-R, Kwon E, E. l. (2017) Evaluating the effectiveness of various biochars as porous media for biodiesel synthesis via pseudo-catalytic transesterification. Bioresour Technol 231:59–64

Dai YM, Chen KT, Wang PH, Chen CC (2016) Solid-base catalysts for biodiesel production by using silica in agricultural wastes and lithium carbonate. Adv Powder Technol 27(6):2432–2438

Ho WW, Ng HK, Gan S, Tan SH (2014) Evaluation of palm oil mill fly ash supported calcium oxide as a heterogeneous base catalyst in biodiesel synthesis from crude palm oil. Energ Convers Manage 8:1167–1178

Roschat W, Siritanon T, Yoosuk B, Promarak V (2016) Rice husk-derived sodium silicate as a highly efficient and low-cost basic heterogeneous catalyst for biodiesel production. Energ Convers Manage 119:453–462

Faba EM, Ferrero OG, Dias MJ, Eimer AG (2018) Thermo-chemically tuning of active basic sites on nanoarchitectured silica for biodiesel production. Molecular Catalysis [In press]. Retrieved from https://doi.org/10.1016/j.mcat.2018.08.013

Chen K-T, Wang J-X, Dai Y-M, Wang P-H, Liou C-Y, Nien C-W et al (2013) Rice husk ash as a catalyst precursor for biodiesel production. J Taiwan Inst Chem Eng 44(4):622–629

Fadhil AB, Aziz AM, Al-Tamer MH (2016) Biodiesel production from Silybum marianum L. seed oil with high FFA content using sulfonated carbon catalyst for esterification and base catalyst for transesterification. Energ Convers Manage 108:255–265

Wan L, Liu H, Skala D (2014) Biodiesel production from soybean oil in subcritical methanol using MnCO3/ZnO as catalyst. Appl Catal B Environ 152-153:352–359

Syazwani ON, Ibrahim ML, Wahyudiono K, Goto M, Taufiq-Yap YH (2017) Esterification of high free fatty acids in supercritical methanol using sulphated angel wing shells as catalyst. J Supercrit Fluids 124:1–9

Lokman IM, Rashid U, Taufiq-Yap YH (2015) Microwave-assisted methyl ester production from palm fatty acid distillate over a heterogeneous carbon-based solid acid catalyst. Chem Eng Technol 38(10):1837–1844

Farabi MSA, Ibrahim ML, Rashid U, Taufiq-Yap YH (2019) Esterification of palm fatty acid distillate using sulfonated carbon-based catalyst derived from palm kernel shell and bamboo. Energ Convers Manage 181:562–570

Gupta AR, Yadav SV, Rathod VK (2015) Enhancement in biodiesel production using waste cooking oil and calcium diglyceroxide as a heterogeneous catalyst in presence of ultrasound. Fuel 158:800–806

Tan YH, Omar Abdullah M, Nolasco-Hipolito C, Taufiq-Yap YH (2015) Waste ostrich- and chicken-eggshells as heterogeneous base catalyst for biodiesel production from used cooking oil: catalyst characterization and biodiesel yield performance. Appl Energy 160:58–70

Buasri A, Chaiyut N, Loryuenyong V, Wongweang C, Khamsrisuk S (2013) Application of eggshell wastes as a heterogeneous catalyst for biodiesel production. Sustain Energy 1(2):7–13

Jain D, Rani A, Khatri C (2010) Fly ash supported calcium oxide as recyclable solid base catalyst for Knoevenagel condensation reaction. Fuel Process Technol 91(9):1015–1021

Acknowledgements

The author would like to express the acknowledgements to the Ministry of Education (MOE) and Universiti Teknologi MARA for the research fund FRGS-RACER research grant 600-IRMI/ FRGS-RACER 5/3 (039/2019) and BESTARI research grant 600-IRMI/PERDANA 5/3 BESTARI (088/2018). Special thanks to Institute of Science (IOS) Universiti Teknologi MARA and Catalysis Science & Technology Research Centre, Universiti Putra Malaysia for all the facilities provided throughout this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. The success preparation of the CaO impregnated SiO2-rich SCBA as the heterogenous solid basic catalyst.

2. The prepared SCBA/CaO catalyst resulted 93.8% of FAME yield at mild reaction conditions for 3 h of transesterification process.

3. The SiO2 improves the reusability of catalyst up to 5 reaction cycles by improving the strength of the active sites-support bonding.

Electronic Supplementary Material

ESM 1

(DOCX 3155 kb)

Rights and permissions

About this article

Cite this article

Abdul Mutalib, A.A., Ibrahim, M.L., Matmin, J. et al. SiO2-Rich Sugar Cane Bagasse Ash Catalyst for Transesterification of Palm Oil. Bioenerg. Res. 13, 986–997 (2020). https://doi.org/10.1007/s12155-020-10119-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10119-6