Abstract

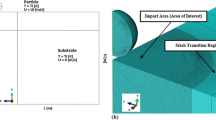

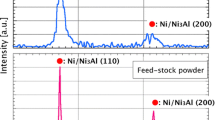

In the practical cold-spraying process, a number of particles impact onto a substrate and then form a coating. To study the deformation behavior and multi-particle interactions, single-particle, two-particle, and three-particle impacts were simulated using the AN-SYS/LS-DYNA version 970. A copper coating was prepared and scanning electron microscopy (SEM) was employed to analyze the microstructures of the powders and the coating. Numerical results reveal that the critical deposition velocity is 600 m/s for a copper particle/copper substrate. The particles deform more fully due to multi-particle interactions, such as tamping, interlocking, and extrusion effects. The compression ratio increases from 40% to 70% as a result of the tamping effect. This is beneficial for achieving the cold-sprayed coating. The multi-particle morphology and compression ratio in the experiment are consistent with those of simulation results. Based on these results, the coating of high performance can be prepared through selecting appropriate parameters and suitable pre-treatment processes.

Similar content being viewed by others

References

C. Xia, X. Peng, and J. Li, Behavior of NiCrAIY coating on the TC6 titanium alloy, J. Univ. Sci. Technol. Beijing, 15(2008), No.2, p.167.

Z.S. Fan, D.B. Sun, H.Y. Yu, et al., Preparation of iron base amorphous and nanocrystalline alloy coatings by plasma spraying, J. Univ. Sci. Technol. Beijing (in Chinese), 27(2005), No.5, p.582.

J. Pattison, S. Celotto, R. Morgan, et al., Cold gas dynamic manufacturing: A non-thermal approach to freeform fabrication, Int. J. Mach. Tools Manuf., 47(2007), No.3–4, p. 627.

B. Jodoin, P. Richer, G. Berube, et al., Pulsed-gas dynamic spraying: process analysis, development and selected coating examples, Surf. Coat. Technol., 201(2007), No.16–17, p.7544.

T. Stoltenhoff, H. Kreye, and H.J. Richter, An analysis of the cold spray process and its coatings, J. Therm. Spray Technol., 11(2002), No.4, p.542.

J.S. Kim, Y.S. Kwon, O.I. Lomovsky, et al., Cold spraying of in situ produced TiB2-Cu nanocomposite powders, Compos. Sci. Technol., 67(2007), No.11–12, p.2292.

S.V. Raj, C. Barrett, J. Karthikeyan, and R. Garlick, Comparison of the cyclic oxidation behavior of cold sprayed CuCrAl-coated and uncoated GRCop-84 substrates for space launch vehicles, Surf. Coat. Technol., 201(2007), No.16–17, p.7222.

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding mechanism in cold gas spraying, Acta Mater., 51(2003), No.15, p.4379.

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process, Mater. Des., 25(2004), No.8, p.681.

M. Grujicic, J.R. Saylor, D.E. Beasley, et al., Computational analysis of the interfacial bonding between feed-powder particles and the substrate in the cold-gas dynamic-spray process, Appl. Surf. Sci., 219(2003), No.3–4, p.211.

T. Schmidt, F. Gartner, H. Assadi, and H. Kreye, Development of a generalized parameter window for cold spray deposition, Acta Mater., 54(2006), No.3, p.729.

K. Yokoyama, M. Watanabe, S. Kuroda, et al., Simulation of solid particle impact behavior for spray processes, Mater. Trans., 47(2006), No.7, p.1697.

W.Y. Li, C. Zhang, X. Guo, et al., Study on impact fusion at particle interfaces and its effect on coating microstructure in cold spraying, Appl. Surf. Sci., 254(2007), No.2, p.517.

C.J. Li, W.Y. Li, and Y.Y. Wang, Formation of metastable phases in cold-sprayed soft metallic deposit, Surf. Coat. Technol., 198(2005), No.1–3, p.469.

X.L. Zhou, X.Y. Su, H. Cui, et al., Effect of material properties of cold-sprayed particles on its impacting behavior, Acta Metall. Sin., 44(2008), No.11, p.1286.

H.B. Zhang, J.B. Zhang, L. Wei, et al., Effect of substrate hardness on impact and deposition of cold-sprayed Cu alloy particles, [in] Proceedings of Yearly Progress of 2006 on Material Science and Engineering—2006 Beijing International Materials Week, Beijing, 2006, p.417.

G.R. Johnson and W.H. Cook, A constitutive model and data for metals subjected to large strains, high rates and high temperatures, [in] Proceedings of the 7th International Symposium on Ballistic, Hague, 1983, p.541.

H.H. Guo, X.L. Zhou, H. Cui, et al., Preparation and simulation of cold sprayed copper coatings on metals substrate, Trans. Mater. Heat Treat., 30(2009), No.6, p.158.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (Nos.50871019 and 50874009) and the National Superiority Discipline Innovation Platform Project (SKL-AMM-CS).

Rights and permissions

About this article

Cite this article

Zhou, Xl., Wu, Xk., Guo, Hh. et al. Deposition behavior of multi-particle impact in cold spraying process. Int J Miner Metall Mater 17, 635–640 (2010). https://doi.org/10.1007/s12613-010-0367-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-010-0367-8