Abstract

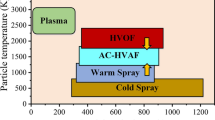

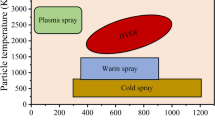

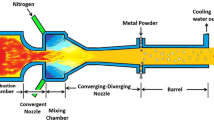

An analysis of a low temperature high velocity air fuel (LTHVAF) thermal spray process is presented using computational fluid dynamics (CFD). The originality of the process lies in the injection of liquid (water) upstream of the powder injection to control to gas temperature and, therefore, the heat transfer to the injected particles. First, computation fluid dynamic techniques are implemented to solve the mass, momentum, and energy conservation equations in the gas phase. A turbulence model based on the renormalized group theory (RNG) is used for the turbulent flow field. The gas dynamic data are, then, used to model the behavior of the liquid droplets and particles in the gas flow field. The calculated results show that the liquid flow rate should range between 20 and 30 kg/h to achieve the optimal gas characteristics for particle treatment. They also show that particle velocity and temperature are strongly affected by particle size. At the gun exit, the particle velocity and temperature range between 700 and 300 m/s and between 900 and 400 K, respectively, for Cu and Ni particles with size distributions of 1 to 50 μm. As expected, the smaller particles have higher velocity and temperature. The metal coatings (Nickel and copper) produced by the LTHVAF spray process are characterized by low oxide content, low residual stresses, high deposition rates, and good bonding to the substrate.

Similar content being viewed by others

References

W. Roge, Kaufold, A. J. Rotolico, J. Nerz. Burton, A. Kushner, Deposition of Coatings Using a New High Velocity Combustion Spray Gun, Therm. Spray Research and Applications, Proc. of 3rd National Therm. Spray Conf., C.C. Berndt, Ed., May 20–25, ASM International, 1990, p 561–574.

B. Zha, H. Wang, X. Su, Structure and Property of WC-17Co Coatings Sprayed by HVO/AF, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., May 5–8, ASM International, 2003, p 837–839.

H. Wang, B. Zha, X. Su. High Velocity Oxygen/Air Fuel Spray, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., May 5–8, ASM International, 2003, p 789–791.

H. Wang, B. Zha. Research of High Velocity Oxygen-Air Fuel Spray, Proceedings of the 3rd International Conference on Surface Engineering, October 10–13 (ChengDu, China), 2002, p 166–168

N. Anatolii, Papyrin, Cold Spray Process of Cost-Sensitive Application, High Performance Metallic Materials for Cost Sensitive Applications, F.H. (Sam) Froes, E. Chen, R.R. Boyer, E.M. Taleff, L. Lu, D.L. Zhang, C.M. Ward-Close, and D. Elizer, Ed., TMS, 2002, p 137–149.

J. Karthikeyan and C.M. Kay, Cold Spray Technology: An Industrial Perspective, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., May 5–8, ASM International, 2003, p 117–121

K. Sakaki and Y. Shimizu, Effect of the Increase in the Entrance Convergent Section Length of the Gun Nozzle on the High-Velocity Oxygen Fuel and Cold Spray Process, J. Therm. Spray Technol., 2001, 10(3), p 487–496.

B. Zha, H. Wang, and K. Xu, Microstructure and Property of LTHVOF Sprayed Copper Coatings, International Thermal Spray Conference & Exposition, E. Lugscheider, Ed., May 2–4, 2005.

J. Karthikyan and C.M. Kay, Cold Spray Nanostructured WC-Co, Thermal Spray 2001: New Surface for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28–30, 2001, (Singapore), ASM International, 2001, p 383–387

N.S. Mahesh, J. Mendonea, M.K. Muralidhara, B.K. Muralidhara, and C. Ramachandra. Modeling of droplet dynamic and thermal behavior during spray deposition. Bull. Mater. Sci., 2003, 26(3), p 355–364

C.M. Hakett, The Influence of Nozzle Design on HVOF Spray Particle Velocity and Temperature, Proceeding of the National Thermal Spray Conference, September 11–15 (Houston, Texas), 1995, p 135–140

P.E. Nylén and R. Bandyopadhyay, Computational Fluid Dynamics Analysis of Gas and Particle Flow in Flame Spraying, Proceedings of the 1st International Thermal Spray Conference, C.C. Berndt, Ed., May 8–11, 2000, p 237–245

D. Choudhury, Introduction to the Renormalization Group Method and Turbulence Modeling. Fluent Inc. Technical Memorandum TM-107, 1993.

FLUENT 6.0 Documentation Fluent Inc. 2001-11-29

B. Zha, H. Wang, and X. Su, Structure and Property of WC-17Co Coatings Sprayed by HVO/AF, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., May 6–8, ASM International, 2003, p 837–839

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yuan, X., Wang, H., Hou, G. et al. Numerical modeling of a low temperature high velocity air fuel spraying process with injection of liquid and metal particles. J Therm Spray Tech 15, 413–421 (2006). https://doi.org/10.1361/105996306X124428

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1361/105996306X124428