Abstract

We studied the electrical properties of polysilicon/hafnium (Hf)-silicate gate stacks with various controlled  compositions, using bis-dimethylamino-silane (BDMAS:

compositions, using bis-dimethylamino-silane (BDMAS:  ) and tris-dimethylamino-silane (TDMAS:

) and tris-dimethylamino-silane (TDMAS:  ) as precursors. The high-

) as precursors. The high- films were fabricated by atomic layer deposition (ALD) using

films were fabricated by atomic layer deposition (ALD) using  and each of the Si precursors in turn.

and each of the Si precursors in turn.  was used as an oxidant. Effective oxide thicknesses (EOTs) were reduced in line with increasing Hf contents: the very thin dielectric

was used as an oxidant. Effective oxide thicknesses (EOTs) were reduced in line with increasing Hf contents: the very thin dielectric  was fabricated with a

was fabricated with a  composition of 74%. The flatband voltage

composition of 74%. The flatband voltage  shift of p-type metal oxide semiconductor field effect transistors (p-MOSFETs) employing either Si precursor were improved by reducing the

shift of p-type metal oxide semiconductor field effect transistors (p-MOSFETs) employing either Si precursor were improved by reducing the  composition: the value of

composition: the value of  shift was improved to about

shift was improved to about  for Hf-silicate gate stacks in which

for Hf-silicate gate stacks in which  composition was reduced from 72–74% to 21–23%. The subthreshold swings (S values) were dependent on the Hf content in the p-MOSFETs employing both Si precursors. By using the gate length (Lg) of the transistors as

composition was reduced from 72–74% to 21–23%. The subthreshold swings (S values) were dependent on the Hf content in the p-MOSFETs employing both Si precursors. By using the gate length (Lg) of the transistors as  ,

,  values varied from

values varied from  /dec for

/dec for  composition ratios from 21 to 74%, respectively, due to a Fermi-level pinning problem. Inspection of subthreshold characteristics of n-MOSFETs revealed values of

composition ratios from 21 to 74%, respectively, due to a Fermi-level pinning problem. Inspection of subthreshold characteristics of n-MOSFETs revealed values of  at

at  , which were greater than

, which were greater than  , while

, while  was less than

was less than  , using either Si precursor

, using either Si precursor  . With the p-MOSFETs, the values of

. With the p-MOSFETs, the values of  at

at  for Hf-silicate gate stacks in which

for Hf-silicate gate stacks in which  composition was between 21 and 23% were approximately

composition was between 21 and 23% were approximately  greater than those in which

greater than those in which  composition was between 72 and 74%. The leakage current densities were dependent on the Hf content in the Hf-silicate gate stacks. However, those were independent of the Si precursors for the Hf-silicate gate stacks with the same Hf content, because the carbon impurity concentrations near the surface of the annealed layers at

composition was between 72 and 74%. The leakage current densities were dependent on the Hf content in the Hf-silicate gate stacks. However, those were independent of the Si precursors for the Hf-silicate gate stacks with the same Hf content, because the carbon impurity concentrations near the surface of the annealed layers at  were about

were about  for both Si precursors.

for both Si precursors.

Export citation and abstract BibTeX RIS

For many years, silicon dioxide  films have been the gate dielectric in complementary metal oxide semiconductor (CMOS) devices. For gate oxide thicknesses of less than

films have been the gate dielectric in complementary metal oxide semiconductor (CMOS) devices. For gate oxide thicknesses of less than  , the direct tunneling current increases by a factor of 100 times for each

, the direct tunneling current increases by a factor of 100 times for each  decrease in thickness.1, 2 This high gate leakage current increases the standby power consumption.2 In order to reduce the leakage current due to direct tunneling, high-dielectric-constant (high-

decrease in thickness.1, 2 This high gate leakage current increases the standby power consumption.2 In order to reduce the leakage current due to direct tunneling, high-dielectric-constant (high- ) materials allow for an increase in the physical thickness while maintaining a low equivalent oxide thickness.3–8 Among the many high-

) materials allow for an increase in the physical thickness while maintaining a low equivalent oxide thickness.3–8 Among the many high- materials available, those based on Hf and its nitride exhibit low leakage currents and high carrier mobility.7, 8

materials available, those based on Hf and its nitride exhibit low leakage currents and high carrier mobility.7, 8

Sputtering and metallorganic chemical vapor deposition (MOCVD) are two methods that have been used for the formation of high- films.3–8 Another possible deposition technique is atomic layer deposition (ALD), which has some desirable features in that it allows precise control of composition, film thickness, conformality, and uniformity.9–15 Hafnium-tetrachloride

films.3–8 Another possible deposition technique is atomic layer deposition (ALD), which has some desirable features in that it allows precise control of composition, film thickness, conformality, and uniformity.9–15 Hafnium-tetrachloride  and water

and water  have been widely used to deposit

have been widely used to deposit  using the ALD technique.9, 10 There have been reports of groups using Hf amide-type precursors such as

using the ALD technique.9, 10 There have been reports of groups using Hf amide-type precursors such as  for growing

for growing  or Hf-aluminate films in order to solve the problem of particles that occurs when using

or Hf-aluminate films in order to solve the problem of particles that occurs when using  precursors.11–16 Furthermore,

precursors.11–16 Furthermore,  and

and  precursors are interesting materials because their melting points are very low (less than

precursors are interesting materials because their melting points are very low (less than  ) and they exhibit high vapor pressures (92 and

) and they exhibit high vapor pressures (92 and  at

at  , respectively).15, 16 It has been reported that the thickness and

, respectively).15, 16 It has been reported that the thickness and  composition ratios of ALD Hf-silicate films could be easily controlled by regulating the number of deposition cycles using

composition ratios of ALD Hf-silicate films could be easily controlled by regulating the number of deposition cycles using  and TDMAS

and TDMAS  , or

, or  and BDMAS

and BDMAS  precursors.15, 16 The flatband/threshold voltage

precursors.15, 16 The flatband/threshold voltage  of poly-Si gated p-type metal oxide semiconductor field effect transistor (p-MOSFETs) formed using Hf-based gate dielectrics is unacceptably high due to Fermi-level pinning.17 Recently, the suppression of these shifts in

of poly-Si gated p-type metal oxide semiconductor field effect transistor (p-MOSFETs) formed using Hf-based gate dielectrics is unacceptably high due to Fermi-level pinning.17 Recently, the suppression of these shifts in  has been studied for Si-rich Hf-silicate gate dielectrics

has been studied for Si-rich Hf-silicate gate dielectrics  in poly-Si gated p-MOSFETs.17–20

in poly-Si gated p-MOSFETs.17–20

In this study, we investigated the effect of  composition on the electrical properties of poly-Si gated n- and p-MOSFETs, incorporating ALD Hf-silicate gate dielectrics that had been fabricated using

composition on the electrical properties of poly-Si gated n- and p-MOSFETs, incorporating ALD Hf-silicate gate dielectrics that had been fabricated using  and TDMAS, or

and TDMAS, or  and BDMAS precursors.

and BDMAS precursors.

Experimental

The substrates that we used were  p-type Si(100) wafers. Immediately following a pretreatment with diluted (0.5%) HF, a

p-type Si(100) wafers. Immediately following a pretreatment with diluted (0.5%) HF, a  -thick SiON layer was formed by rapid thermal processing (RTP) in an NO ambient at

-thick SiON layer was formed by rapid thermal processing (RTP) in an NO ambient at  for

for  to prevent boron penetration and interfacial layer growth. After the underlayer formation, Hf-silicate films were deposited by using an ALD technique.

to prevent boron penetration and interfacial layer growth. After the underlayer formation, Hf-silicate films were deposited by using an ALD technique.  was used to form the

was used to form the  layers, and TDMAS or BDMAS were used to form the

layers, and TDMAS or BDMAS were used to form the  layers. A single ALD cycle for

layers. A single ALD cycle for  consisted of the following process: the

consisted of the following process: the  precursor was introduced into the reactor chamber for

precursor was introduced into the reactor chamber for  , after which it was purged for

, after which it was purged for  . This precursor was introduced using a liquid flow meter system and vaporized at

. This precursor was introduced using a liquid flow meter system and vaporized at  with Ar as a carrier gas. Following this,

with Ar as a carrier gas. Following this,  was introduced for

was introduced for  as an oxidant and then purged for

as an oxidant and then purged for  . The

. The  and the carrier gas had flow rates of

and the carrier gas had flow rates of  and

and  , respectively. A single ALD cycle for

, respectively. A single ALD cycle for  consisted of the following process: the Si precursor was introduced into the reactor chamber for

consisted of the following process: the Si precursor was introduced into the reactor chamber for  and was then purged for

and was then purged for  , and an oxidant

, and an oxidant  was introduced for

was introduced for  and purged for

and purged for  . In this ALD

. In this ALD  process, BDMAS was directly introduced into the reactor chamber and controlled using a mass flow system at

process, BDMAS was directly introduced into the reactor chamber and controlled using a mass flow system at  , because the vapor pressure of BDMAS is very high. The BDMAS had a flow rate of

, because the vapor pressure of BDMAS is very high. The BDMAS had a flow rate of  in order to obtain good uniformity of better than 5%. TDMAS was introduced into the reactor chamber using a liquid mass flow system and vaporized at

in order to obtain good uniformity of better than 5%. TDMAS was introduced into the reactor chamber using a liquid mass flow system and vaporized at  with Ar as a carrier gas. The TDMAS and carrier gas have flow rates of 10 and

with Ar as a carrier gas. The TDMAS and carrier gas have flow rates of 10 and  , respectively, to obtain good uniformity of better than 5%. In the process, a buffer gas of Ar always flowed at

, respectively, to obtain good uniformity of better than 5%. In the process, a buffer gas of Ar always flowed at  into the reactor chamber.

into the reactor chamber.  was used as a source of oxygen using an

was used as a source of oxygen using an  flow ratio of

flow ratio of  with the concentration of

with the concentration of  in

in  being

being  . The pressure in the ALD reactor chamber was controlled at

. The pressure in the ALD reactor chamber was controlled at  for

for  deposition, and at

deposition, and at  and

and  for TDMAS-

for TDMAS- and BDMAS-

and BDMAS- deposition, respectively.15, 16 The film depositions were carried out at

deposition, respectively.15, 16 The film depositions were carried out at  . The

. The  compositions of the ALD Hf-silicate films were controlled by varying the

compositions of the ALD Hf-silicate films were controlled by varying the  ratio in the gas-phase: compositions of 23, 44, and 74% were achieved for ratios of

ratio in the gas-phase: compositions of 23, 44, and 74% were achieved for ratios of  ,

,  , and

, and  for TDMAS; and 21, 48, and 72% were achieved for ratios of

for TDMAS; and 21, 48, and 72% were achieved for ratios of  ,

,  , and

, and  for BDMAS, respectively.15, 16

for BDMAS, respectively.15, 16

In this transistor device fabrication process, counterimplantation was applied to reduce the  for p-MOSFETs after the well formation.21 The channel doping concentrations were about 5 and

for p-MOSFETs after the well formation.21 The channel doping concentrations were about 5 and  for n-MOS and p-MOSFETs, respectively. After the formation of high-

for n-MOS and p-MOSFETs, respectively. After the formation of high- gate stack dielectrics, the films were nitrided using a nitrogen radical plasma treatment.8 The nitrogen plasma was formed in an

gate stack dielectrics, the films were nitrided using a nitrogen radical plasma treatment.8 The nitrogen plasma was formed in an  ambient at

ambient at  at

at  using a

using a  radio frequency (rf) power supply. After nitridation, the films were treated in an

radio frequency (rf) power supply. After nitridation, the films were treated in an  -diluted oxygen atmosphere (

-diluted oxygen atmosphere ( concentration of 0.1%) at

concentration of 0.1%) at  for

for  as a postnitridation annealing (PNA). Polysilicon was then deposited on the high-

as a postnitridation annealing (PNA). Polysilicon was then deposited on the high- gate stack to provide the gate electrodes, and boron and phosphorus were implanted as p- and n-type dopants, respectively. After patterning and etching of the polysilicon gate electrodes, rapid thermal annealing (RTA) was performed at

gate stack to provide the gate electrodes, and boron and phosphorus were implanted as p- and n-type dopants, respectively. After patterning and etching of the polysilicon gate electrodes, rapid thermal annealing (RTA) was performed at  for

for  to activate the dopants. The samples were then annealed at

to activate the dopants. The samples were then annealed at  for

for  in forming gas (

in forming gas ( mixture).

mixture).

The film thickness and uniformity of the Hf-silicate and  films were measured with an ellipsometer over

films were measured with an ellipsometer over  wafers. The composition of the Hf-silicate films was measured using high-resolution Rutherford backscattering (HR-RBS) analysis with a

wafers. The composition of the Hf-silicate films was measured using high-resolution Rutherford backscattering (HR-RBS) analysis with a  helium ion

helium ion  beam. Capacitance-voltage (C-V) and current-voltage (I-V) measurements were performed in parallel on an HP 4284A LCR meter at high frequency

beam. Capacitance-voltage (C-V) and current-voltage (I-V) measurements were performed in parallel on an HP 4284A LCR meter at high frequency  and an HP 4156C parameter analyzer. The effective oxide thicknesses (EOT) and flatband voltage

and an HP 4156C parameter analyzer. The effective oxide thicknesses (EOT) and flatband voltage  of the films were calculated using an analytical quantum mechanical model.22 The effective mobility was measured by applying a modified split C-V method. The interfacial trap density (Nit) was evaluated from the charge-pumping current (Icp) at room temperature.14 Residual impurities such as carbon and hydrogen were analyzed by secondary ion mass spectrometry (SIMS) with a

of the films were calculated using an analytical quantum mechanical model.22 The effective mobility was measured by applying a modified split C-V method. The interfacial trap density (Nit) was evaluated from the charge-pumping current (Icp) at room temperature.14 Residual impurities such as carbon and hydrogen were analyzed by secondary ion mass spectrometry (SIMS) with a  cesium primary ion

cesium primary ion  beam. The primary ion beam was raster scanned over an area of

beam. The primary ion beam was raster scanned over an area of  .

.

Results and Discussion

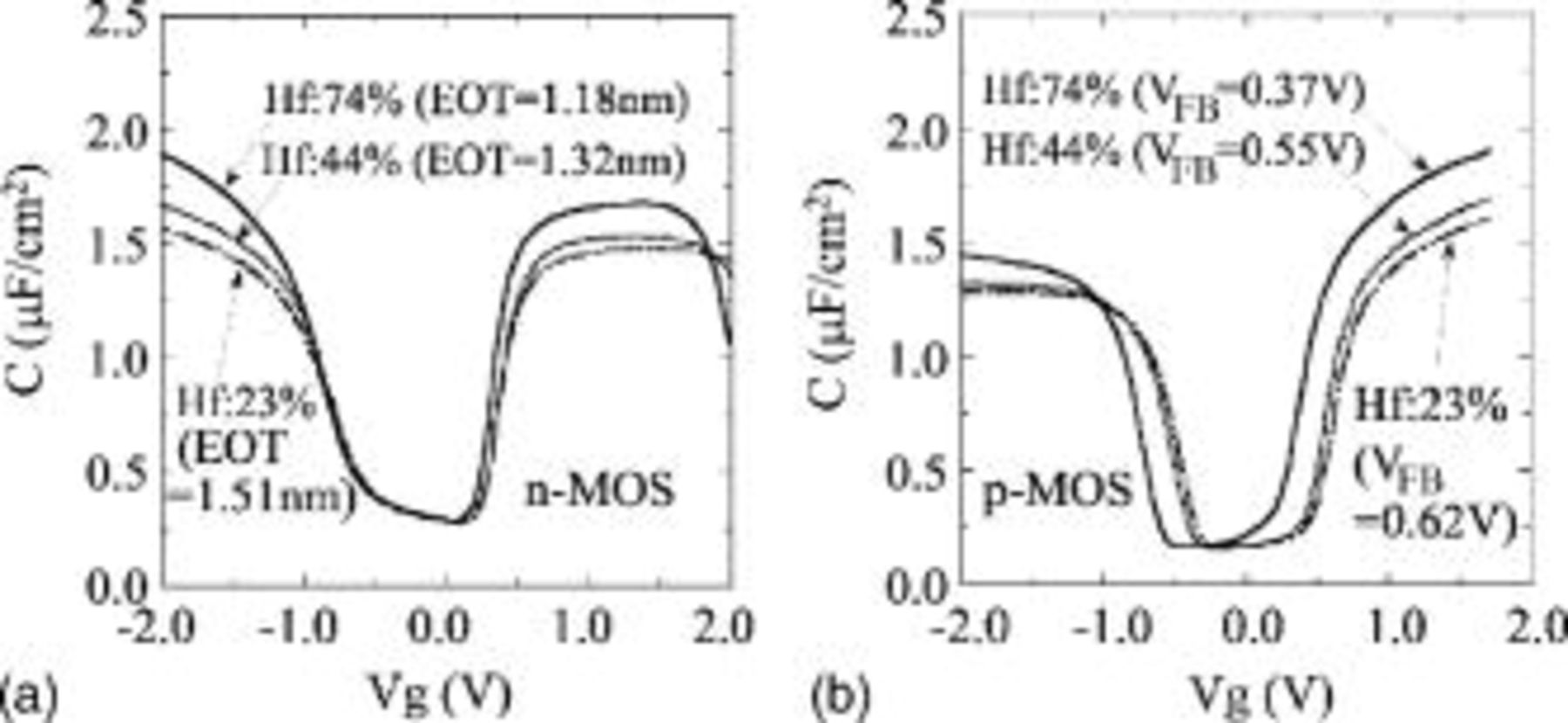

Figure 1 shows the C-V characteristics of ALD Hf-silicate gate stacks employing TDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Hf-silicate films were evaluated with three different Hf contents (Hf 74% using  , Hf 44% using

, Hf 44% using  , and Hf 23% using

, and Hf 23% using  ratio). As shown in Fig. 1, the EOTs of these films were 1.18, 1.32, and

ratio). As shown in Fig. 1, the EOTs of these films were 1.18, 1.32, and  for

for  compositions of 74, 44, and 23%, respectively, in the Hf-silicate gate stacks: the EOTs were reduced with increasing Hf contents due to increases in their dielectric constant

compositions of 74, 44, and 23%, respectively, in the Hf-silicate gate stacks: the EOTs were reduced with increasing Hf contents due to increases in their dielectric constant  . The

. The  of all of the n-MOSFETs were almost the same, however, those of the p-MOSFETs were dependent on the Hf content of the Hf-silicate gate stacks.

of all of the n-MOSFETs were almost the same, however, those of the p-MOSFETs were dependent on the Hf content of the Hf-silicate gate stacks.

Figure 1. C-V characteristics of ALD Hf-silicate gate stacks employing TDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Hf-silicate films were evaluated with three different Hf contents (Hf 74% using  , Hf 44% using

, Hf 44% using  , and Hf 23% using

, and Hf 23% using  ratios). C-V measurements were performed using capacitors with an area of

ratios). C-V measurements were performed using capacitors with an area of

. The EOT and flatband voltage

. The EOT and flatband voltage  were calculated from the analytical quantum mechanical model.22

were calculated from the analytical quantum mechanical model.22

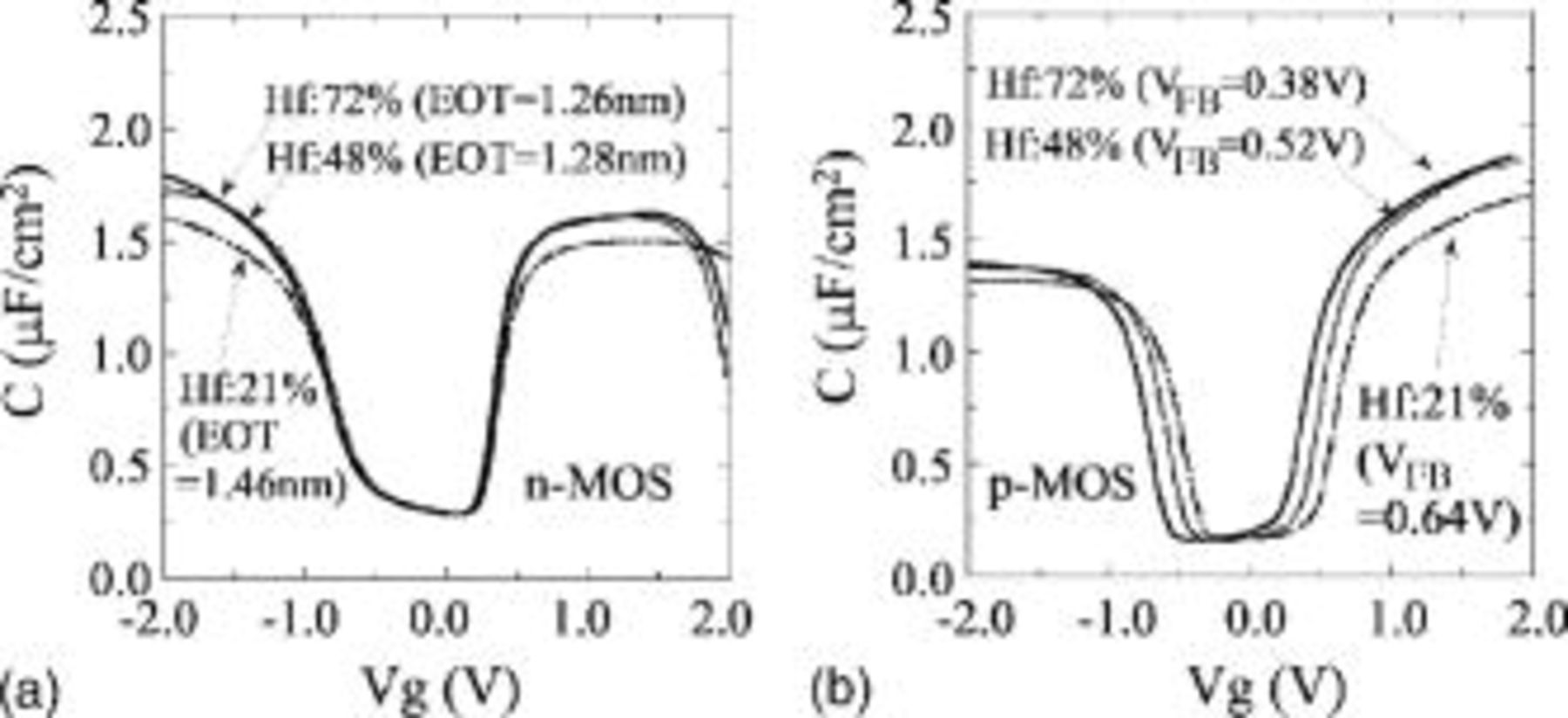

Figure 2 shows the C-V characteristics of ALD Hf-silicate gate stacks employing BDMAS for (a) n-MOSFETs and (b) p-MOSFETs. The Hf-silicate films possessed almost the same Hf contents as in the TDMAS case; the  compositions of 72, 48, and 21% were achieved with ratios of

compositions of 72, 48, and 21% were achieved with ratios of  ,

,  , and

, and  , respectively. As shown in Fig. 2, the values of EOT were reduced with increasing Hf contents and the

, respectively. As shown in Fig. 2, the values of EOT were reduced with increasing Hf contents and the  values of the p-MOSFETs were also dependent on the Hf contents of the Hf-silicate gate stacks.

values of the p-MOSFETs were also dependent on the Hf contents of the Hf-silicate gate stacks.

Figure 2. C-V characteristics of ALD Hf-silicate gate stacks employing BDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Hf-silicate films were evaluated with three different HF contents (Hf 72% using  , Hf 48% using

, Hf 48% using  , and Hf 21% using

, and Hf 21% using  ratios).

ratios).

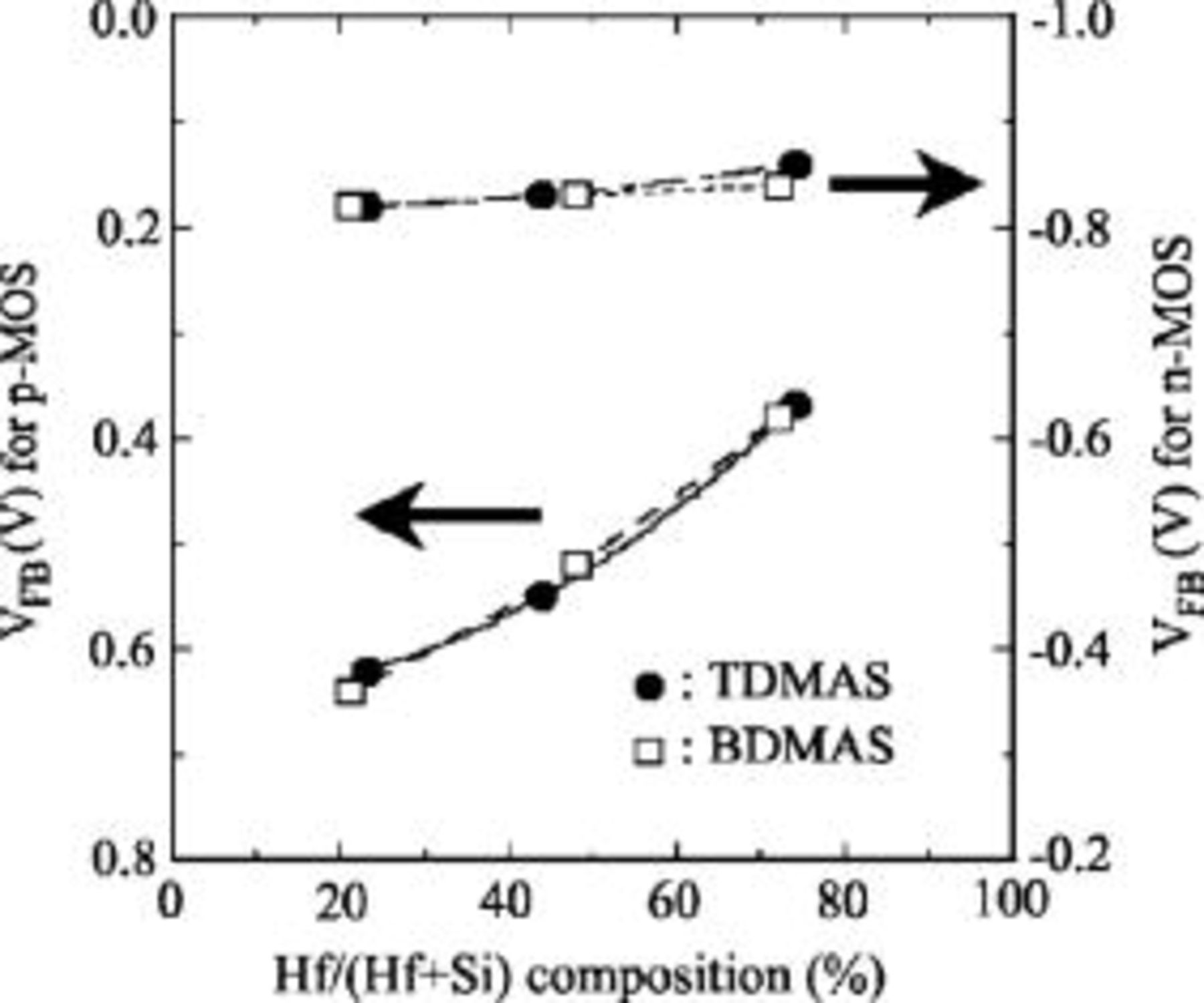

Figure 3 shows the dependence of  on the

on the  composition in the ALD Hf-silicate gate stacks, using TDMAS and BDMAS precursors, for n- and p-MOSFETs. As shown in Fig. 3, values of

composition in the ALD Hf-silicate gate stacks, using TDMAS and BDMAS precursors, for n- and p-MOSFETs. As shown in Fig. 3, values of  of n-MOSFETs were slightly increased by reducing the

of n-MOSFETs were slightly increased by reducing the  composition: the value of

composition: the value of  shift was about

shift was about  . Values of

. Values of  shift of p-MOSFETs were improved by reducing the

shift of p-MOSFETs were improved by reducing the  composition: the improved value of

composition: the improved value of  shift was about

shift was about  for

for  compositions of 23–21%. Furthermore, these results were not dependent on the Si precursors. This probably occurs because the Fermi-level pinning problem is suppressed by Si-rich Hf-silicate films; however, there is still the Fermi-level pinning problem because the value of

compositions of 23–21%. Furthermore, these results were not dependent on the Si precursors. This probably occurs because the Fermi-level pinning problem is suppressed by Si-rich Hf-silicate films; however, there is still the Fermi-level pinning problem because the value of  is about

is about  for the poly-

for the poly- sample using the same conditions of device fabrication process.17–20 The reason for this result is still not fully understood.

sample using the same conditions of device fabrication process.17–20 The reason for this result is still not fully understood.

Figure 3. Dependence of  on the

on the  composition in the ALD Hf-silicate gate stacks, using TDMAS and BDMAS precursors, for n- and p-MOSFETs.

composition in the ALD Hf-silicate gate stacks, using TDMAS and BDMAS precursors, for n- and p-MOSFETs.

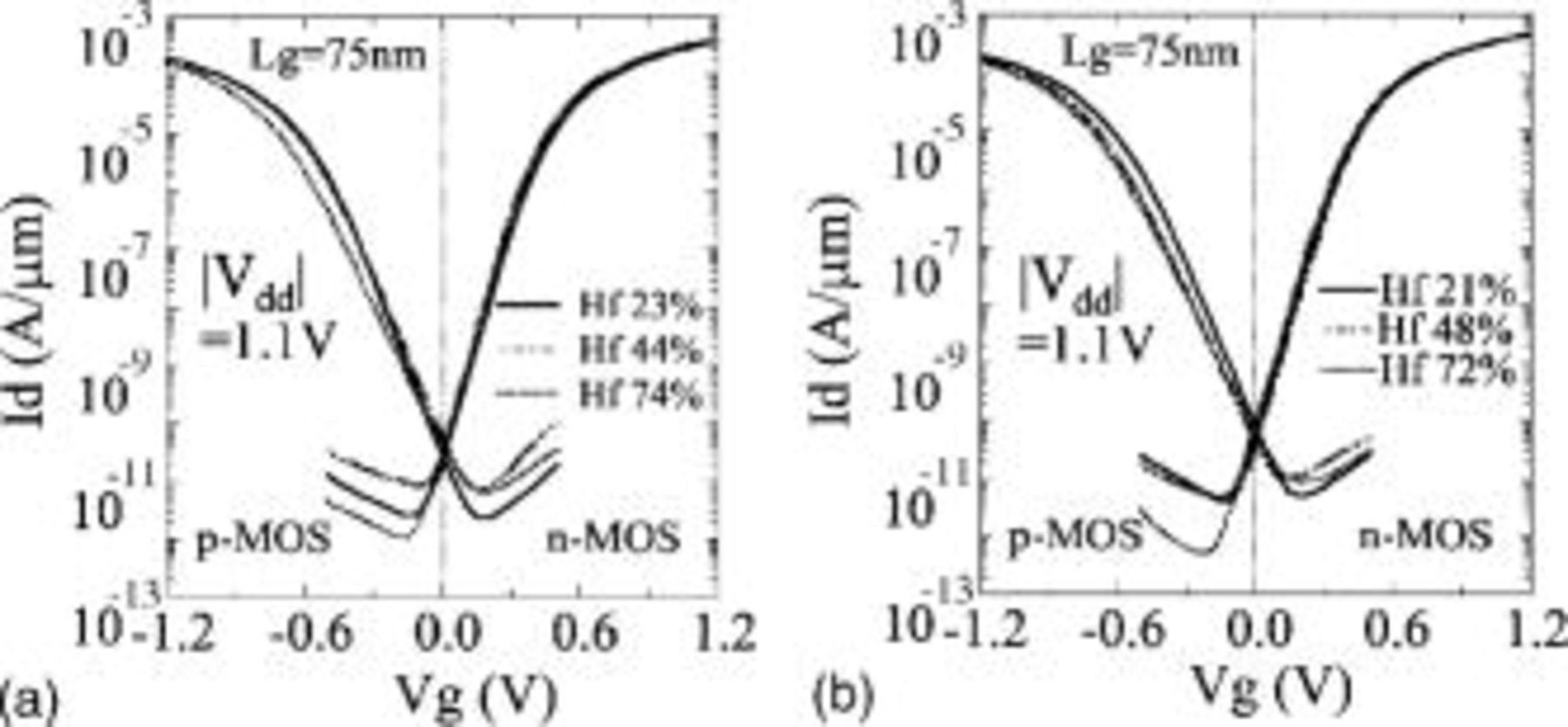

Figure 4 shows the subthreshold characteristics of ALD Hf-silicate gate stacks with different Hf contents using (a) TDMAS and (b) BDMAS precursors. In this measurement, the gate length (Lg) and the gate width  of the transistors used were

of the transistors used were  and

and  , and the applied voltages between the drain and the source were 1.1 and

, and the applied voltages between the drain and the source were 1.1 and  for the n- and p-MOSFETs, respectively. The subthreshold swings (

for the n- and p-MOSFETs, respectively. The subthreshold swings ( values) for all samples were good, being less than

values) for all samples were good, being less than  /dec for n-MOSFETs. The S values were dependent on the Hf content of Hf-silicate gate stacks for p-MOSFETs: these varied from

/dec for n-MOSFETs. The S values were dependent on the Hf content of Hf-silicate gate stacks for p-MOSFETs: these varied from  /dec for

/dec for  compositions from 21 to 74%, respectively. The drain currents

compositions from 21 to 74%, respectively. The drain currents  at

at  were less than

were less than  in both n- and p-MOSFETs. The drain current

in both n- and p-MOSFETs. The drain current  at

at  in the n-MOSFETs fabricated using BDMAS were larger than those using TDMAS because the values of

in the n-MOSFETs fabricated using BDMAS were larger than those using TDMAS because the values of  of BDMAS devices were slightly larger than those using TDMAS. The values of

of BDMAS devices were slightly larger than those using TDMAS. The values of  were greater than about

were greater than about  . Meanwhile, the values of

. Meanwhile, the values of  in the p-MOSFET samples were dependent on the Hf-content. The values of

in the p-MOSFET samples were dependent on the Hf-content. The values of  for Hf-silicate gate stacks containing

for Hf-silicate gate stacks containing  compositions of 72–74% were about

compositions of 72–74% were about  less than the values in devices with

less than the values in devices with  compositions of 21–23%, probably due to the Fermi-level pinning problem. The processing parameters and electrical properties of these samples are summarized in Table I.

compositions of 21–23%, probably due to the Fermi-level pinning problem. The processing parameters and electrical properties of these samples are summarized in Table I.

Figure 4. Subthreshold characteristics of ALD Hf-silicate gate stacks with different Hf contents, using (a) TDMAS and (b) BDMAS precursors. In this (Lg) and the gate width  of the transistors used were

of the transistors used were  and

and  , and the applied voltages between the drain and the source were 1.1 and

, and the applied voltages between the drain and the source were 1.1 and  for the n- and p-MOSFETs, respectively. The value of the threshold voltage was defined as the gate voltage for

for the n- and p-MOSFETs, respectively. The value of the threshold voltage was defined as the gate voltage for  for n- and p-MOSFETs.

for n- and p-MOSFETs.

Table I. Processing parameters and electrical properties of ALD Hf-silicate gate stacks using TDMAS and BDMAS precursors.

| Si Precorsors |

ratio ratio |

composition composition |

at at

|

at at

| S (mV/dec.) | |||

|---|---|---|---|---|---|---|---|---|

| n-MOS | p-MOS | n-MOS | p-MOS | p-MOS | p-MOS | |||

| 23% | 320 | 152 | 20 | 30 | 74 | 92 | |

| TDMAS |

| 44% | 352 | 155 | 26 | 60 | 72 | 96 |

| 74% | 340 | 118 | 29 | 45 | 71 | 102 | |

| 21% | 379 | 159 | 52 | 62 | 75 | 94 | |

| BDMAS |

| 48% | 389 | 134 | 31 | 43 | 73 | 99 |

| 72% | 390 | 115 | 74 | 66 | 74 | 105 | |

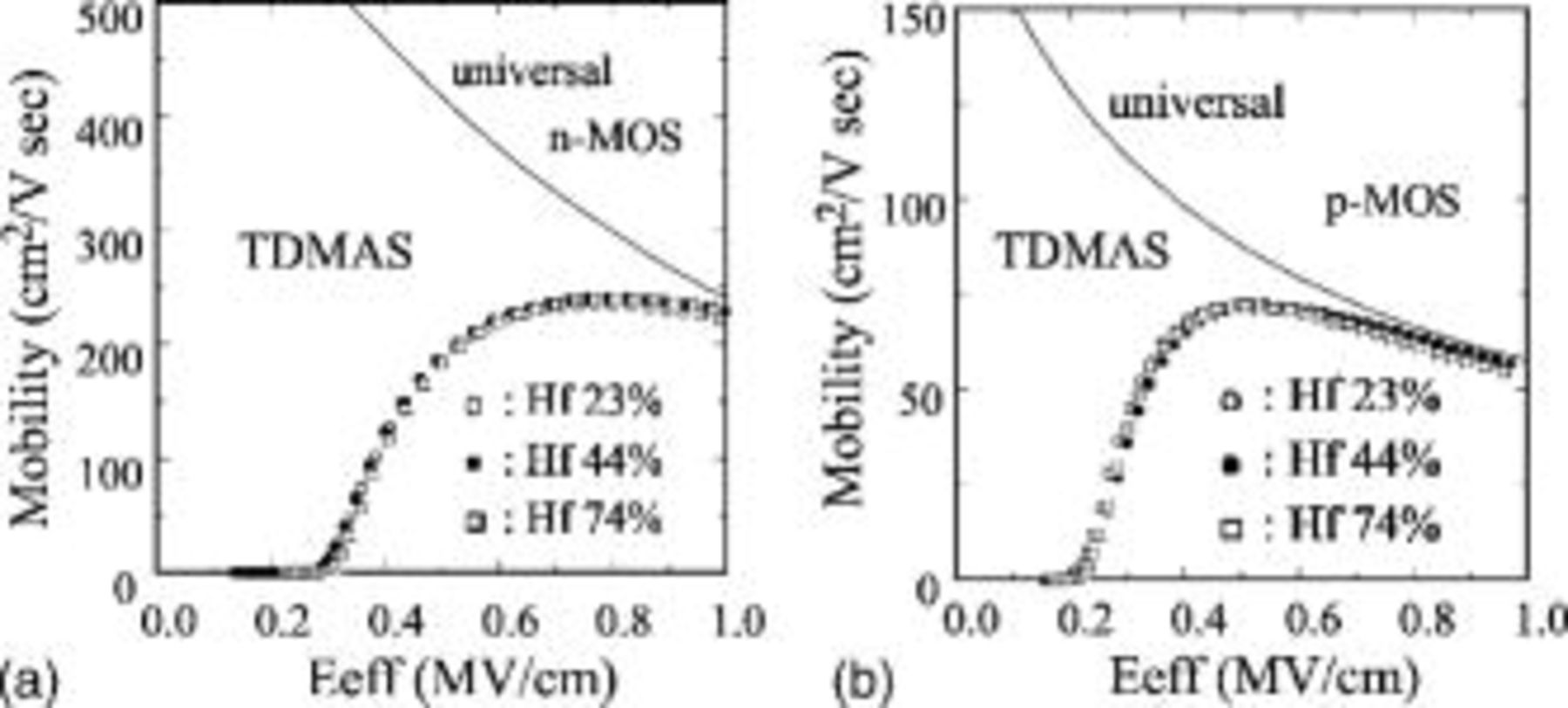

Figure 5 shows the effective mobility curves of ALD Hf-silicate gate stacks employing TDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Universal curves are shown for reference. Hf-silicate films were evaluated with three different Hf contents (Hf 74% using  , Hf 44% using

, Hf 44% using  , and Hf 23% using

, and Hf 23% using  ratio). The effective mobility was measured by applying a modified split C-V method. As shown in Fig. 5, the effective curves were good for both n-MOS and p-MOSFETs, being the same level as that of reference universal curves at

ratio). The effective mobility was measured by applying a modified split C-V method. As shown in Fig. 5, the effective curves were good for both n-MOS and p-MOSFETs, being the same level as that of reference universal curves at  . Furthermore, the effective mobility curves did not vary between the Hf contents [

. Furthermore, the effective mobility curves did not vary between the Hf contents [ 23–74%] for either n-MOS and p-MOSFETs.

23–74%] for either n-MOS and p-MOSFETs.

Figure 5. Effective mobility curves of ALD Hf-silicate gate stacks employing TDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Universal curves are shown for reference. Hf-silicate films were evaluated with three different Hf contents (Hf 74% using  , Hf 44% using

, Hf 44% using  , and Hf 23% using

, and Hf 23% using  ratio). The effective mobility was measured by applying a modified split C-V method.

ratio). The effective mobility was measured by applying a modified split C-V method.

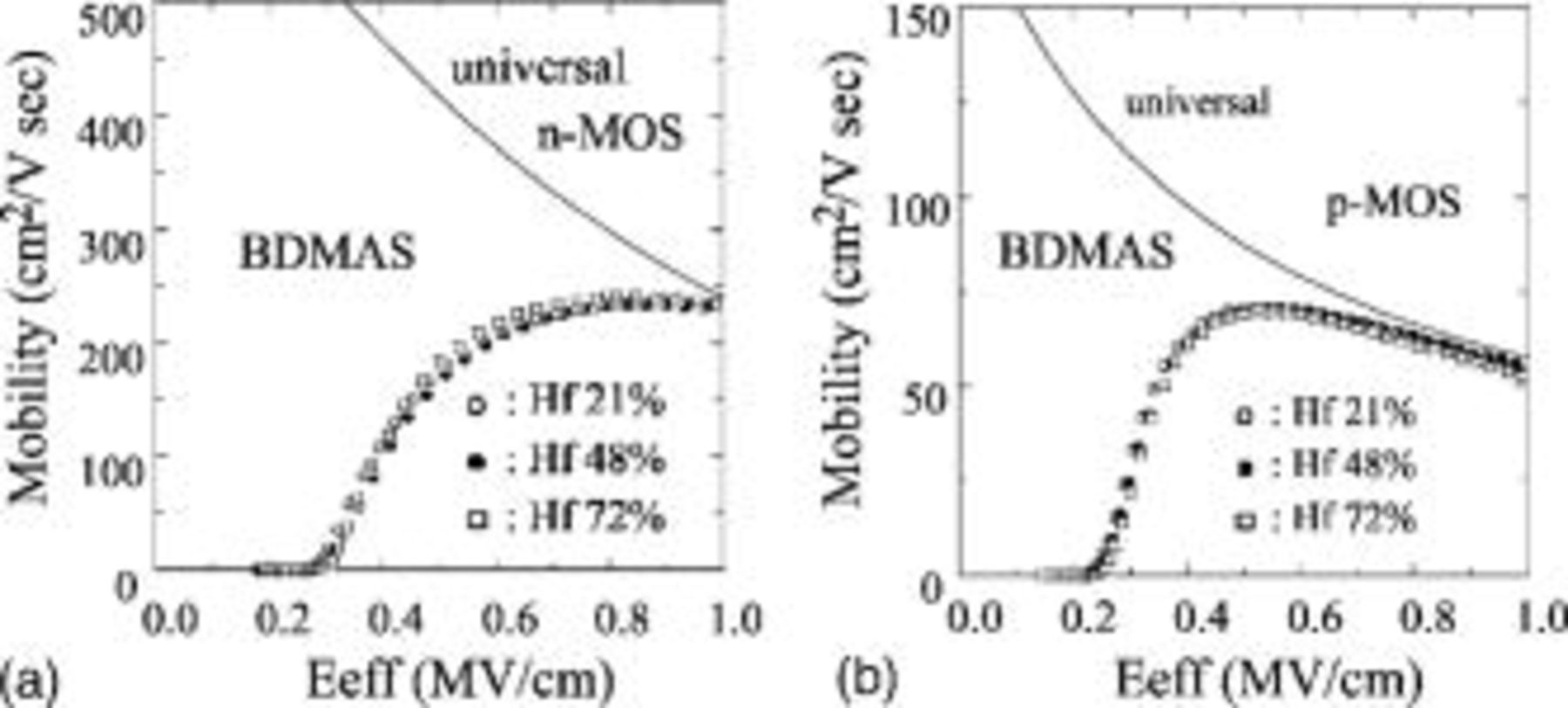

Figure 6 shows the effective mobility curves of ALD Hf-silicate gate stacks employing BDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Hf-silicate films were evaluated with three different Hf contents (Hf 72% using  , Hf 48% using

, Hf 48% using  , and Hf 21% using

, and Hf 21% using  ratio). The effective curves were good for both n-MOS and p-MOSFETs, and the effective mobility curves did not vary between the Hf contents (

ratio). The effective curves were good for both n-MOS and p-MOSFETs, and the effective mobility curves did not vary between the Hf contents ( 21–72%) for either n-MOS or p-MOSFETs. Also, the effective mobility curves of Hf-silicate gate stacks employing BDMAS were almost the same as those employing TDMAS (Fig. 5) for all of the n-MOS and p-MOSFETs.

21–72%) for either n-MOS or p-MOSFETs. Also, the effective mobility curves of Hf-silicate gate stacks employing BDMAS were almost the same as those employing TDMAS (Fig. 5) for all of the n-MOS and p-MOSFETs.

Figure 6. Effective mobility curves of ALD Hf-silicate gate stacks employing BDMAS for (a) n-MOSFETs and (b) p-MOSFETs. Hf-silicate films were evaluated with three different Hf contents (Hf 72% using  , Hf 48% using

, Hf 48% using  , and Hf 21% using

, and Hf 21% using  ratio).

ratio).

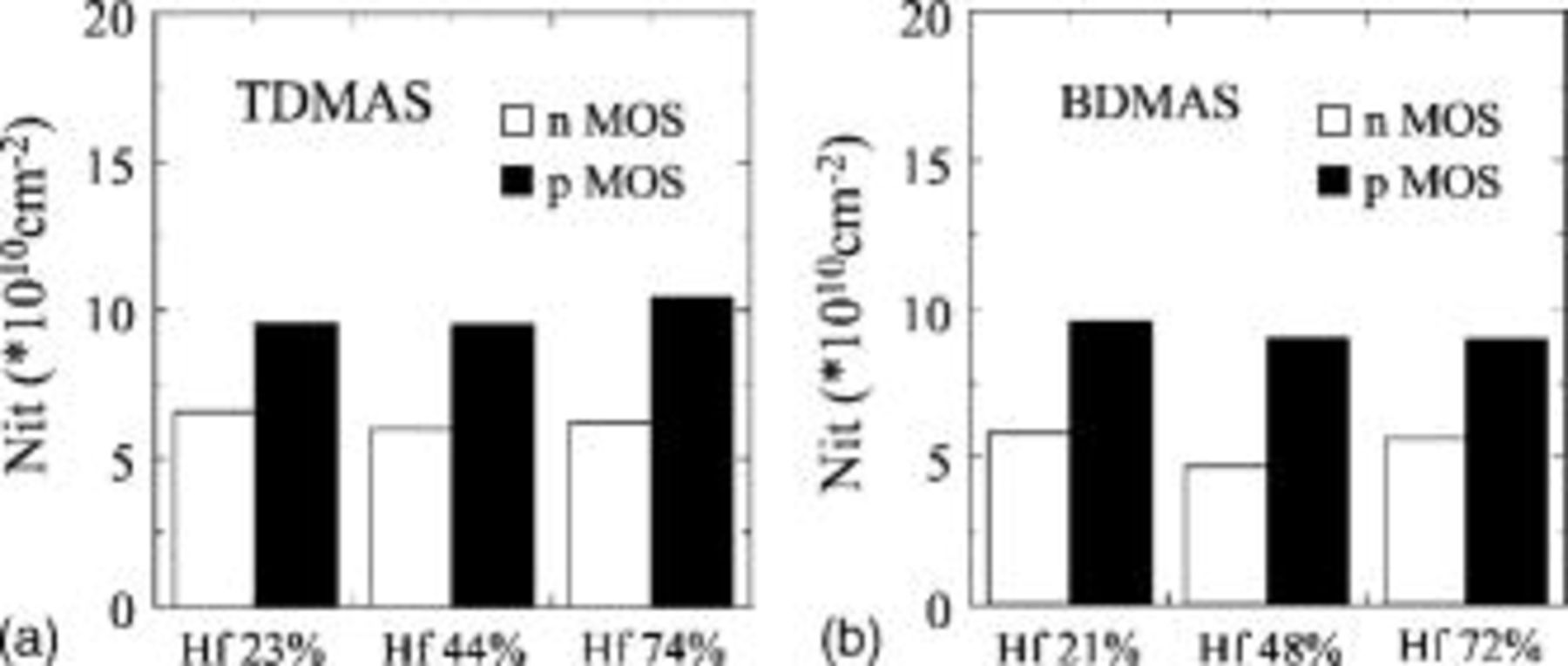

Figure 7 shows the number of interface trap density (Nit) of ALD Hf-silicate gate stacks employing (a) TDMAS and (b) BDMAS for both n-MOS and p-MOSFETs. As shown in Fig. 7, the interface trap densities for all n-MOSFET devices were low, despite using high- gate stacks. Trap densities of about

gate stacks. Trap densities of about  for all n-MOSFETs were almost the same level as those with the

for all n-MOSFETs were almost the same level as those with the  SiON reference film.14, 23 Therefore, the effective mobility curves did not vary between the Hf contents [

SiON reference film.14, 23 Therefore, the effective mobility curves did not vary between the Hf contents [ 21–74%] and using TDMAS and BDMAS precursors for n-MOSFETs. However, the interface trap densities for all p-MOSFET devices were higher than those with the

21–74%] and using TDMAS and BDMAS precursors for n-MOSFETs. However, the interface trap densities for all p-MOSFET devices were higher than those with the  SiON reference film. For p-MOSFETs, the effective mobility is not so sensitive to the interface trap density, so the effective mobility is not changed for all ALD Hf-silicate gate stacks employing TDMAS and BDMAS precursors (Fig. 5 and 6).

SiON reference film. For p-MOSFETs, the effective mobility is not so sensitive to the interface trap density, so the effective mobility is not changed for all ALD Hf-silicate gate stacks employing TDMAS and BDMAS precursors (Fig. 5 and 6).

Figure 7. Interface trap density (Nit) of ALD Hf-silicate gate stacks employing (a) TDMAS and (b) BDMAS for both n-MOS and p-MOSFETs. Nit was evaluated from the charge-pumping current (Icp) at room temperature. In this measurement, the gate length (Lg) and the gate width  used were 0.5 and

used were 0.5 and  , respectively.

, respectively.

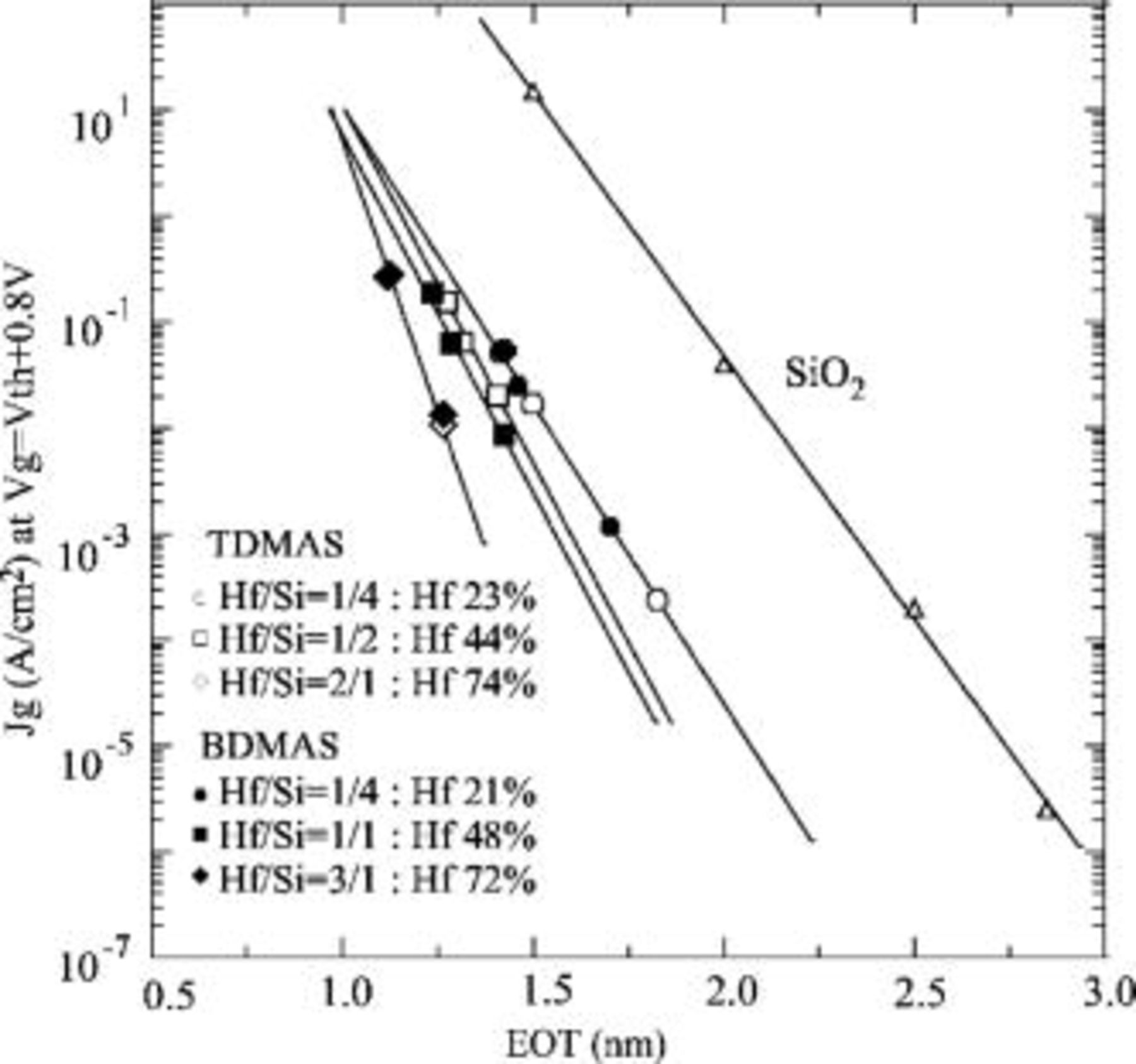

Figure 8 shows the leakage current density at  as a function of EOT for n-MOSFETs. Thermal oxide data is also given for reference. The I-V measurements were performed using capacitors with an area of

as a function of EOT for n-MOSFETs. Thermal oxide data is also given for reference. The I-V measurements were performed using capacitors with an area of

. The leakage current density in Hf-silicate gate stacks with

. The leakage current density in Hf-silicate gate stacks with  were reduced by about 3 orders of the magnitude with respect to a reference

were reduced by about 3 orders of the magnitude with respect to a reference  film. Furthermore, the leakage current densities were dependent on the Hf content of the Hf-silicate gate stacks: the leakage current densities were reduced as the Hf content increased because all of the devices were fabricated with same thickness, resulting in thinner EOTs. Furthermore, the leakage current densities were not dependent on the Si precursors.

film. Furthermore, the leakage current densities were dependent on the Hf content of the Hf-silicate gate stacks: the leakage current densities were reduced as the Hf content increased because all of the devices were fabricated with same thickness, resulting in thinner EOTs. Furthermore, the leakage current densities were not dependent on the Si precursors.

Figure 8. Leakage current density at  as a function of EOT for n-MOSFETs. I-V measurements were performed using capacitors with an area of

as a function of EOT for n-MOSFETs. I-V measurements were performed using capacitors with an area of

.

.

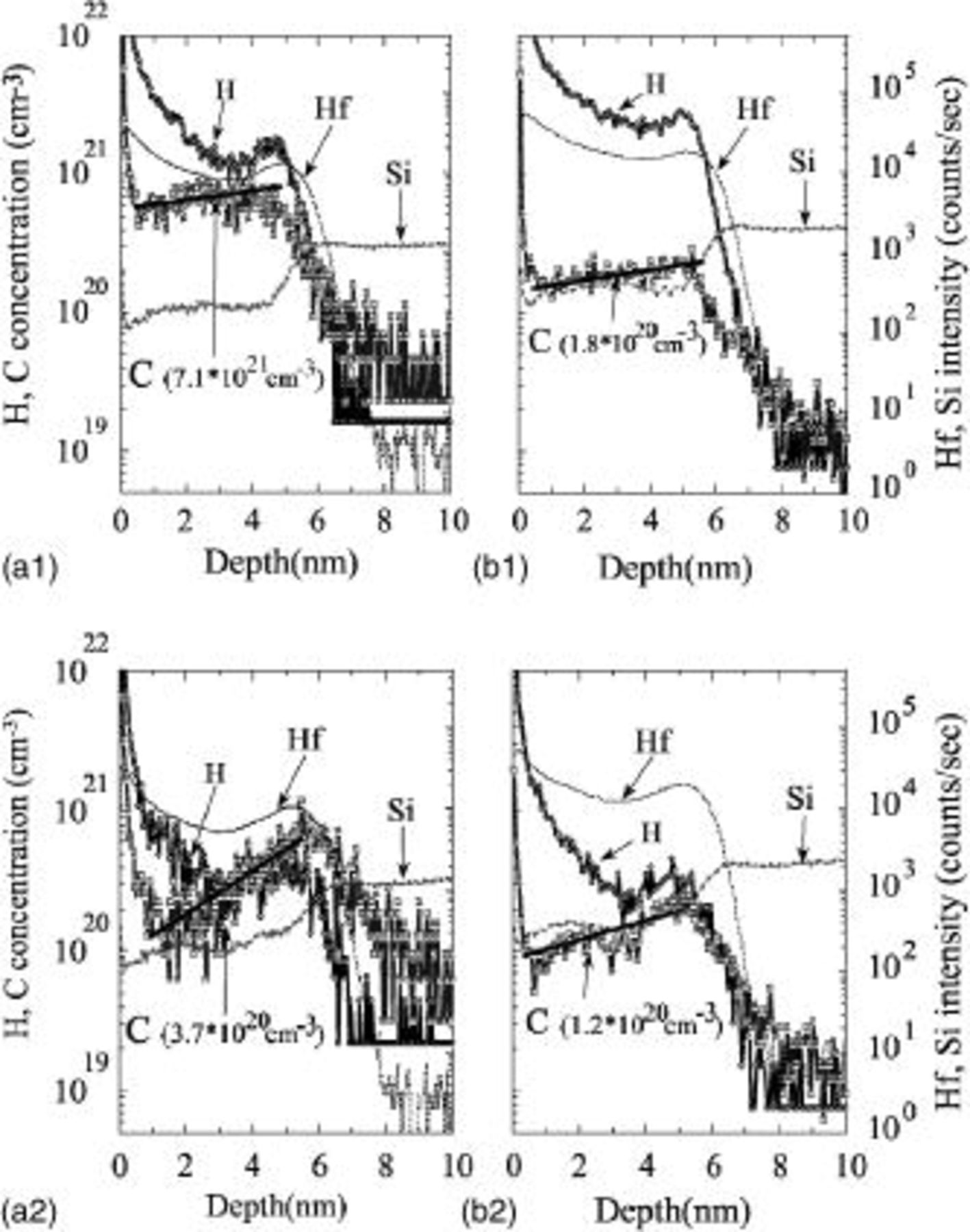

Figure 9 shows SIMS depth profiles of ALD Hf-silicate films using (a) TDMAS and (b) BDMAS precursors. In these results, a  ratio of 1:1 was used in each ALD Hf-silicate film formation, and all the films were deposited at

ratio of 1:1 was used in each ALD Hf-silicate film formation, and all the films were deposited at  . The

. The  compositions of the Hf-silicate films were 56 and 48% using TDMAS and BDMAS, respectively. As can be seen in Fig. 9a-1, the average residual carbon impurity concentrations in the as-deposited layer using TDMAS were

compositions of the Hf-silicate films were 56 and 48% using TDMAS and BDMAS, respectively. As can be seen in Fig. 9a-1, the average residual carbon impurity concentrations in the as-deposited layer using TDMAS were  . For ALD Hf-silicate film formation using BDMAS (as shown in Fig. 9a-2), the carbon impurity concentrations were reduced by about an order of magnitude with respect to the process using TDMAS. As shown in Fig. 9b-1 and 9b-2, the average residual carbon impurity concentrations in the annealed layer, using both Si precursors, were reduced by about a half order of magnitude compared with the as-deposited layers. Furthermore, as the carbon impurity concentrations near the surface of the annealed layers were about

. For ALD Hf-silicate film formation using BDMAS (as shown in Fig. 9a-2), the carbon impurity concentrations were reduced by about an order of magnitude with respect to the process using TDMAS. As shown in Fig. 9b-1 and 9b-2, the average residual carbon impurity concentrations in the annealed layer, using both Si precursors, were reduced by about a half order of magnitude compared with the as-deposited layers. Furthermore, as the carbon impurity concentrations near the surface of the annealed layers were about  for both Si precursors, it was considered that the electrical properties would be almost the same for the Hf-silicate gate stacks with the same Hf content.

for both Si precursors, it was considered that the electrical properties would be almost the same for the Hf-silicate gate stacks with the same Hf content.

Figure 9. SIMS depth profiles of ALD Hf-silicate films using TDMAS (a) and BDMAS (b) precursors. (a-1) and (b-1) The as-deposited case, and (a-2) and (b-2) that treated by high-temperature annealing at  for

for  in

in  -diluted oxygen atmosphere (

-diluted oxygen atmosphere ( concentration of 0.1%), respectively.

concentration of 0.1%), respectively.  ratios of 1:1 were used in each ALD Hf-silicate film formation and all the films were deposited at

ratios of 1:1 were used in each ALD Hf-silicate film formation and all the films were deposited at  . SIMS analyses were done with a

. SIMS analyses were done with a  cesium primary ion

cesium primary ion  beam. The concentrations

beam. The concentrations  of carbon and hydrogen impurities are indicated by the left ordinate and the secondary ion intensities of Hf and Si (counts/s) are indicated by the right ordinate.

of carbon and hydrogen impurities are indicated by the left ordinate and the secondary ion intensities of Hf and Si (counts/s) are indicated by the right ordinate.

Conclusions

We investigated the electrical properties of poly-Si/ALD Hf-silicate gate stacks fabricated using BDMAS and TDMAS precursors. The high- films were fabricated using atomic layer deposition (ALD) employing

films were fabricated using atomic layer deposition (ALD) employing  and each of the Si precursors, in which the

and each of the Si precursors, in which the  composition was controlled. The EOTs were reduced in line with increasing Hf contents: the very thin dielectric

composition was controlled. The EOTs were reduced in line with increasing Hf contents: the very thin dielectric  was fabricated with a

was fabricated with a  composition of 74%. The

composition of 74%. The  shifts of p-MOSFETs were improved by reducing the

shifts of p-MOSFETs were improved by reducing the  composition: the value of the

composition: the value of the  shifts was improved to about

shifts was improved to about  for Hf-silicate gate stacks in which

for Hf-silicate gate stacks in which  composition was reduced from 72–74% to 21–23%. The subthreshold swings were dependent on the Hf content in the p-MOSFETs for both Si precursors.

composition was reduced from 72–74% to 21–23%. The subthreshold swings were dependent on the Hf content in the p-MOSFETs for both Si precursors.  values were varied from

values were varied from  /dec for

/dec for  compositions from 21 to 74%, respectively, due to the Fermi-level pinning problem

compositions from 21 to 74%, respectively, due to the Fermi-level pinning problem  . Inspecting the subthreshold characteristics of n-MOSFETs, the values of

. Inspecting the subthreshold characteristics of n-MOSFETs, the values of  at

at  were greater than

were greater than  and

and  was lower than

was lower than  with both Si precursors

with both Si precursors  . With p-MOSFETs, the values of

. With p-MOSFETs, the values of  at

at  for Hf-silicate gate stacks in which

for Hf-silicate gate stacks in which  was about

was about  greater than those in which

greater than those in which  . The leakage current densities were dependent on the Hf content in the Hf-silicate gate stacks. However, those were independent of the Si precursors for the Hf-silicate gate stacks with the same Hf content, because the carbon impurity concentrations near the surface of the annealed layers at

. The leakage current densities were dependent on the Hf content in the Hf-silicate gate stacks. However, those were independent of the Si precursors for the Hf-silicate gate stacks with the same Hf content, because the carbon impurity concentrations near the surface of the annealed layers at  were about

were about  for both Si precursors.

for both Si precursors.

Acknowledgment

The authors thank Dr. K. Nakamura for his encouragement and useful discussions.

Semiconductor Leading Edge Technologies (Selete), Incorporated, assisted in meeting the publication costs of this article.