Abstract

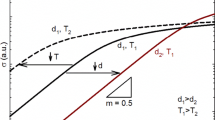

In several recent experiments on the Zn-22% Al eutectoid and the Pb-62% Sn eutectic, a sigmoidal relationship between stress and strain rate is noted and the mechanical behaviour has been divided into three regions: low-stress region (region I), intermediatestress region (the superplastic region or region II), and high-stress region (region III). In region II, the stress exponent,n, is ≃ 2 and the apparent activation energy,Q, is close to grain-boundary diffusion,Q gb, but in both regions I and III the stress exponent and the activation energy increase (n > 2 andQ >Q gb). Analysis of the experimental data of the two superplastic alloys suggests that the transition in behaviour between region II and region I may not necessarily reflect a change in deformation process but can arise from the presence of a threshold stress which decreases strongly with increasing temperature. Based on consideration of various possible threshold stress processes during superplastic flow, it seems most likely that a threshold stress which depends strongly on temperature may result from impurity atom segregation at boundaries and their interaction with boundary dislocations.

Similar content being viewed by others

References

J. B. Bird, A. K. Mukherjee andJ. E. Dorn, in “Quantitative Relations Between Properties and Microstructure”, edited by D. G. Brandon and A. Rosen (Israel Universities Press, Jerusalem, 1969) p. 255.

F. A. Mohamed andT. G. Langdon,Acta. Metall. 23 (1975) 117.

F. A. Mohamed, S. A. Shei andT. G. Langdon,ibid. 23 (1975) 1443.

F. A. Mohamed andT. G. Langdon,Phil. Mag. 32 (1975) 697.

G. Rai andN. J. Grant,Met. Trans. 6A (1975) 385.

A. Arieli andA. K. Mukherjee,Scripta Metall. 13 (1979) 331.

D. Grivas, Report No. LBL-7375, Lawrence Berkeley Laboratory, University of California, Berkeley (1978).

S. H. Vale, D. J. Eastgate andP. M. Hazzledine,Scripta Metall. 13 (1979) 1157.

D. W. Livesey andN. Ridley,ibid. 16 (1982) 165.

F. A. Mohamed andT. G. Langdon,Acta. Metall. 29 (1981) 911.

R. H. Johnson,Met. Rev. 15 (1970) 115.

A. V. Karim andW. A. Backofen,Met. Trans. ASM 3 (1972) 709.

B. Burton,Scripta Metall. 5 (1971) 669.

M. F. Ashby andR. A. Verrall,Acta Metall 21 (1973) 148.

J. H. Gittus,J. Eng. Mater. Technol. 99 (1977) 244.

T. G. Langdon andF. A. Mohamed,Scripta Metall. 11 (1977) 575.

Idem, J. Aust. Inst. Met. 22 (1977) 189.

R. C. Gifkins,Met. Trans. 7A (1976) 1225.

Idem, J. Mater. Sci. 13 (1978) 1928.

C. I. Smith, B. Norgate andN. Ridley,Scripta Metall. 8 (1974) 159.

F. A. Mohamed andT. J. Ginter,J. Mater. Sci. 16 (1981) 2890.

F. A. Mohamed,ibid. 17 (1982) 1381.

H. Ishikawa, F. A. Mohamed andT. G. Langdon,Phil. Mag. 32 (1979) 269.

A. Ball andM. M. Hutchinson,Met. Sci. J. 3 (1969) 1.

A. K. Mukherjee,Mater. Sci. Eng. 8 (1971) 83.

M. F. Ashby,Scripta Metall. 3 (1969) 837.

Idem, Surface Sci. 31 (1972) 498.

C. A. P. Horton,Scripta Metall. 8 (1974) 1.

J. Friedel, “Dislocations” (Pergamon Press, Oxford, 1964) Ch. 16.

J. Weertman.Acta Metall. 25 (1977) 1393.

Idem, Trans. Amer. Inst. Min. Eng. 218 (1960) 207.

J. D. Eshelby,Phil. Mag. 6 (1961) 953.

F. R. N. Nabarro, Report of a Conference on Strength on Solids (The Physical Society, London, 1948) p. 78.

C. Herring,J. Appl. Phys. 21 (1950) 437.

R. L. Coble,Ibid. 34 (1963) 1679.

B. Burton, “Diffusional Creep on Poly crystalline Material” (Trans. Tech. Publications, Bay Village, Ohio, 1977).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mohamed, F.A. Interpretation of superplastic flow in terms of a threshold stress. J Mater Sci 18, 582–592 (1983). https://doi.org/10.1007/BF00560647

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00560647