Abstract

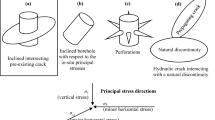

Explosive loading in borehole configurations has been investigated to assess the relative importance of internal gas pressurization and stress-wave-induced circumferential tensions for extending radial cracks originating at the borehole walls. Simple calculations of an extending crack (with and without confining pressure) were performed to estimate an upper bound on crack length resulting solely from internal pressurization for comparison with the crack length resulting solely from tensile stresses. These calculations indicated that a internal gas pressure could increase the crack length by a factor of 10 to 100 (no confining pressure) or 3 to 25 [6.9-MPa (1000-psi) confining pressure] compared with the tensile stresses acting alone. Simple laboratory experiments were performed using 3.2 × 10−3m diameter (1/8in.) by 1.52 × 10−1m long (6 in.) borehole charges centered in a 1.3 × 10−2m diameter (1/2in.) borehole in transparent Plexiglas cylinders 3 × 10−1m in diameter by 3 × 10−1m long (12in. by 12in.) to verify these computational results. Two tests were performed: one with a thin (5.08 × 10−4m) steel liner to contain the explosive gases and one without a liner so that the explosive gases could enter and pressurize the fractures. A confining pressure of 6.9 MPa (1000 psi) was applied to the Plexiglas cylinders in both experiments to better simulate field conditions and to contain the cracks within the cylinder; all other experimental conditions were identical. These experiments indicated that the primary effect of the explosive gases was to increase crack length by a factor of five to ten compared with the tensile stresses acting alone, in approximate agreement with the predictions.

Résumé

Une mise en charge explosive dans des configurations d'alésages a été étudiée en vue d'établir l'importance relative de la pression interne de gaz et des tensions circonférentielles induites par l'onde des contraintes pour des fissures radiales en cours d'extension prenant leur origine sur les parois de l'alésage. Des calculs simples d'une fissure en cours d'extension avec ou sans pression de confinement on été effectués en vue d'estimer une frontière supérieure de longueur de fissure qui résulterait seulement de la pression interne, à comparer avec la longueur de fissure qui résulterait seulement des contraintes de traction. Ces calculs ont indiqué que la pression interne de gaz pouvait accroitre la longueur d'une fissure d'un facteur 10 à 100 (sans pression de confinement) ou de 3 à 25 (dans le cas d'une pression de confinement de 6,5 MPa (1000-psi)), lorsqu'on se rapporte à l'action simple des contraintes de traction. Des essais simples de laboratoire ont été effectués en utilisant des charges cylindriques de 3,2 mm 0 sur 152 mm de long disposées dans un alésage de 13 mm 0 foré dans des cylindres de plexiglas transparent de 30 mm 0 sur 30 mm de long, en vue de vérifier les résultats du calcul. Deux essais ont été effectués: l'un recourant à un mince chambrage en acier (1/2 mm) en vue de contenir les gaz de l'explosion et l'autre sans chambrage, de sorte que les gaz de l'explosion pouvaient pénétrer et pressuriser les fissures. Une pression de confinement de 6,9 MPa (1000-psi) a été appliquée aux cylindres de plexiglas dans les deux types d'essai en vue de simuler au mieux les conditions réelles et de contenir les fissures dans le cylindre; toutes les autres conditions d'essai étaient identiques. Ces essais ont indiqué que l'effet principal des gaz résultant de l'explosion était d'accroitre la fissure d'un facteur de 5 à 10, par rapport au cas où les contraintes de traction agissent seules. Ceci est en accord approximatif avec les prédictions.

Similar content being viewed by others

References

S.L. McHugh, P.S. De Carli, and D. Keough, “Small-Scale Field Experiments with An Analysis to Evaluate the Effects of Tailored Pulse Loading on Fracture and Permeability”, SRI Annual Report to Department of Energy, Morgantown Energy Technology Center, Morgantown, WV, SRI Project PYU 8621, SRI International Menlo Park (1980).

R.A. Schmidt, N.R. Warpinski, P.W. Cooper, “In Situ Evaluation of Several Tailored-Pulse Well-Shooting Concepts”, paper presented at Society off Petroleum Engineers Meeting, Pittsburg, PA (May 1980).

I.N. Sneddon and H.A. Elliott,Quarterly Applied Mathematics 4 (1946) 262–267.

O.L. Bowie,Journal of Mathematics and Physics 35 (1956) 60–71.

H. Kutter,International Journal of Fracture Mechanics 6 (1970) 233–247.

T.P. Bligh, inAdvances in Rock Mechanics, Proceedings of the Third Congress of the International Society for Rock Mechanics (Denver, CO) Vol. 2, Part B (1974) 1421–1425.

M.P. Hardy, “Fracture Mechanics Applied to Rock,” Pb.D. thesis, University of Minnesota (1973).

C.M. Lownds,Journal of South African Institute of Mining and Metallurgy 165–180.

R.A. Westmann,Journal of Mathematics and Physics 44 (1977) 619–624.

P.S. Theocaris and N.J. Ioakimidis,Journal of Applied Mechanics 44 (1977) 619–624.

U. Langefors and B. Kihlstrom,The Modern Technique of Rock Blasting, third edition, Halstead Press, John Wiley and Sons (1978).

F. Ouchterlony, inProceedings of the Third Congress ofthe International Society Rock Mechanics (Denver, CO) (1974) 1377–1383.

L.D. Clark and S.S. Saluja,Transactions American Institute of Mining Engineers 229 (1964) 78–90.

S.S. Saluja, inStatus of Practical Rock Mechanics, Proceedings of the Ninth Symposium on Rock Mechanics (Golden, CO) American Institute of Mining Engineers (1968) 297–319.

C.H. Johansson and P.A. Persson, inProceedings of the Third Congress of the International Society for Rock Mechanics (Denver, CO) (1974) 1557–1566.

F. Ouchterlony,Engineering Fracture Mechanics 8 (1976) 447–448.

H.K. Kutter and C. Fairhurst, inPractical Rock Mechanics, Proceedings Ninth Symposium on Rock Mechanics (Golden, CO) American Institute of Mining Engineers (1968) 265–284.

D.D. Porter and C. Fairhurst, inDynamic Rock Mechanics, Proceedings of the Twelfth Symposium on Rock Mechanics (Rolla, MO) American Institute of Mining Engineers (1971) 497–515.

N.R. Warpinski, R.A. Schmidt, H.C. Walling, P.W. Cooper and S.J. Finley, “High Energy Gas Frac.,” Sandia Report SAND 78-2342, Sandia Laboratories, Albuquerque, NM (December 1978).

J.W. Dally, W.L. Fourney and D.C. Holloway,International Journal of Rock Mechanics Mining Science and Geomechanics, Abstract 12 (1975) 5–12.

D.L. Coursen,Acta Astronautica 6 (1979) 341–363.

L. Seaman, “A Computational Model for Dynamic Tensile Microfracture with Damage in One Plane,” SRI Poulter Laboratory Technical Report 001-80, SRI International, Menlo Park (February 1980).

L. Seaman, and D.R. Curran, “PUFF 8 Computer Program For One-Dimensional Stress Wave Propagation,” SRI Final Report to U.S. Army Ballistics Research Laboratory, MD, SRI Project PYU 6802, SRI International, Menlo Park (1978).

S.L. McHugh, W.J. Murri, L. Seaman, D.R. Curran and D.D. Keough, “Fracture of Devonian Shale by Tailored Pulse Loading,” SRI Final Report to Department of Energy, Morgantown Energy Technology Center, Morgantown, WV, SRI Project PYU 6700, SRI International, Menlo Park (December 1978).

S.L. McHugh, “The Effect of Explosive Gases on the Fracture Process in a Geologic Solid,” SRI Poulter Laboratory Technical Report 002-79, SRI International, Menlo Park (November 1979).

D.J. Cagliostro, “Experiments on the Response of Hexagonal Subassembly Ducts to Radial Loads,” SRI Second Interim Report to Argonne National Laboratory, SRI Project PYD 1960, SRI International, Menlo Park (August 1975).

A.H. Shapiro,The Dynamics and Thermodynamics of Compressible Fluid Flow, Volumes I and II, Ronald Press Co., New York (1953).

Author information

Authors and Affiliations

Additional information

This work was partially sponsored by the Department of Energy, Morgantown Energy Technology Center, Morgantown, WV, under Contract No. DE-AC21-79-MC11577.

Rights and permissions

About this article

Cite this article

McHugh, S. Crack extension caused by internal gas pressure compared with extension caused by tensile stress. Int J Fract 21, 163–176 (1983). https://doi.org/10.1007/BF00963386

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00963386