Abstract

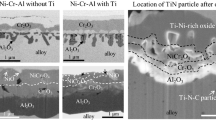

The solidification behaviour of tin droplets embedded in an aluminium matrix in a rapidly solidified Al-5 wt % Sn alloy has been investigated by a combination of transmission electron microscopy and differential scanning calorimetry. Detailed transmission electron microscopy shows that rapidly solidified Al-5 wt % Sn consists of about 5 μm diameter columnar aluminium grains, with a fine-scale distribution of 20–300 nm sized tin particles embedded within the aluminium grains, and 100–400 nm sized tin particles at the aluminium grain boundaries. The tin particles exhibit two different orientation relationships with the aluminium matrix and a variety of different faceted shapes: {1 1 1}Al∥{1 0 0}Sn and 〈¯2 1 1〉Al∥〈0 1 0〉Sn, with the main facet parallel to {1 1 1}Al, and {1 0 0}Sn; and {1 0 0}Al∥{1 0 0}Sn and 〈0 1 1〉Al∥〈0 1 1〉Sn, with the main facet parallel to {1 0 0}Al and {1 0 0}Sn.In situ heating in the transmission electron microscope shows that the different tin particle shapes are not affected by heat treatment in the solid state, but change into a truncated octahedral shape bounded by {1 1 1}Al and {1 0 0}Al facets when the tin particles melt. The {1 0 0}Al-liquid Sn interfacial energy is about 9% larger than the {1 1 1}Al-liquid Sn interfacial energy just above the tin particle melting point, and the {1 0 0}Al/{1 1 1}Al interfacial energy anisotropy decreases gradually as the temperature increases above the melting point. Differential scanning calorimeter experiments show that the liquid tin droplets solidify in three stages. Firstly, the larger tin droplets at the aluminium grain boundaries solidify by nucleation on catalytic trace impurities, over a temperature range of 170–140 °C. Secondly and thirdly, the smaller tin particles embedded within the aluminium grains solidify by catalytic nucleation on the {1 0 0}Al and {1 1 1}Al facets, over the two temperature ranges of 140–128 °C and 128-115°C. Catalytic nucleation of the solidification of tin takes place at special sites such as steps or dislocations on the {1 0 0}Al and {1 1 1}Al facets with contact angles of 55° and 59°.

Similar content being viewed by others

References

J. W. Christian, “The Theory of Transformations in Metals and Alloys” (Pergamon, Oxford 1975).

B. Vonnegut,J. Colloid Sci. 3 (1948) 563.

D. Turnbull,J. Chem. Phys. 18 (1950) 768.

J. H. Perepezko, D. H. Rasmussen, I. E. Anderson andC. R. Roper, “Solidification and Casting of Metals” (Metals Society, London, 1979) p. 169.

Y. Miyazawa andG. M. Pound,J. Crystal Growth 23 (1974) 45.

J. H. Perepezko et al., “Rapid Solidification Processing: Principles and Technology”, edited by R. Mehrabian, B. H. Kear and M. Cohen (Claitors, Baton Rouge, 1980) p. 56.

J. H. Perepezko,Mater. Sci. Engng 65 (1984) 125.

J. H. Perepezko andJ. S. Smith,J. Non-Cryst. Solids 44 (1981) 65.

J. H. Perepezko andJ. S. Paik,ibid 61/62 (1984) 113.

M. G. Chu, Y. Shiohara andM. C. Flemings,Met. Trans. 15A (1984) 1303.

D. Turnbull andR. E. Cech,J. Appl. Phys. 21 (1950) 804.

D. Turnbull,J. Metals 188 (1950) 1144.

M. J. Stowell,Phil. Mag. 22 (1970) 1.

R. E. Sundquist andL. F. Mondolfo,Trans. AIME 221 (1961) 157.

R. E. Cech andD. Turnbull,ibid. 206 (1956) 124.

A. J. Drehman andA. L. Greer,Acta Metall. 32 (1984) 323.

A. J. Drehman andD. Turnbull,Scripta Metall. 15 (1981) 543.

G. H. Abbaschian andM. C. Flemings,Met. Trans. 14A (1983) 1147.

T. Z. Kattamis andM. C. Flemings,Trans. TMS-AIME 236 (1966) 1523.

W. T. Kim, PhD thesis, Seoul National University, Seoul (1987).

J. Fehling andE. Scheil,Z. Metallkde 53 (1962) 593.

S. N. Ojha, T. R. Anantharaman andP. Ramachandrarao,J. Mater. Sci. 17 (1982) 264.

T. Z. Kattamis andM. C. Flemings,Met. Trans. 1 (1970) 1449.

K. I. Moore, D. L. Zhang andB. Cantor,Acta Metall., in press.

C. C. Wang andC. S. Smith,Trans. AIME 188 (1950) 136.

R. T. Southin andG. A. Chadwick,Acta Metall. 26 (1978) 223.

P. G. Boswell andG. A. Chadwick,ibid. 28 (1980) 209.

K. I. Moore, K. Chattopadhyay andB. Cantor,Proc. Roy. Soc. A414 (1987) 499.

K. I. Moore andB. Cantor, in “Solidification and Casting of Metals II” (Metals Society, London, 1987) p. 515.

D. L. Zhang andB. Cantor,J. Mater. Sci., in press.

Idem, Phil. Mag.,A62 (1990) 557.

A. J. McAlister andD. J. Kahan,Bull. Alloy Phase Diag. 4 (1983) 410.

G. Wulff,Z. Kristallogr. 53 (1901) 440.

D. Turnbull,J. Appl. Phys. 21 (1950) 1022.

B. Cantor andR. D. Doherty,Acta Metall. 27 (1979) 33.

W. T. Kim, D. L. Zhang andB. Cantor,Met. Trans. in press.

L. M. Mondolfo, N. L. Parisi andG. J. Kardys,Mat. Sci. Engng 68 (1984–85) 249.

E. A. Brandes andC. J. Smithells, “Metals Reference Book”, 6th Edn (Butterworths, London, 1983).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, W.T., Cantor, B. Solidification of tin droplets embedded in an aluminium matrix. J Mater Sci 26, 2868–2878 (1991). https://doi.org/10.1007/BF01124815

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01124815