Abstract

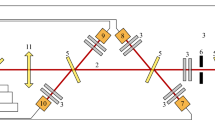

Heat and mass transport, structurization, and residual-stress formation in the course of laser-ultrasonic hardening, near-surface alloying, rapid crystallization of melts, and pattern cutting are experimentally studied with allowance made for the theoretical concept that ultrasound influences the processes of phase transformations and diffusion under conditions of high-rate laser heating and subsequent cooling. It is shown that harder and deeper hardening zones and melt baths are formed under the laser-ultrasonic treatment. Plastic deformation of the surface by ultrasound significantly affects the completeness of austenitic transformation and thus makes it possible to efficiently control the strained state of the surface in the zone exposed to laser radiation. Acoustic flows emerging in the laser-induced melt smooth the temperature nonuniformities and the topography of the melt surface efficiently even when the duration of the laser exposure is about 1 ms. The influence of the geometry of injecting the ultrasound on the structurization and formation of residual stresses during rapid crystallization of the laser-induced melt and the subsequent tempering was observed. It was established that the injection of ultrasound into the laser-induced melt brings about a more efficient alloying and better micromechanical characteristics of the surface. The laser-ultrasonic pattern cutting of metal without the formation of flashes was realized.

Similar content being viewed by others

References

H. Haken,Advanced Synergetics: Instability Hierarchies of Self-Organizing Systems and Devices, Springer, New York (1983).

O. V. Abramov, V. I. Dobatkin, V. F. Kazatsev, et al.,The Influence of High-Power Ultrasound on the Interphase Surface in Metals [in Russian], Nauka, Moscow (1986).

L. D. Landau and E. M. Lifshits,Hydrodynamics [in Russian], Nauka, Moscow (1986).

V. N. Gridnev, Yu. Ya. Meshkov, S. P. Oshkaderov, and V. I. Trefilov,Physical Basics of Electrothermal Hardening of Steel [in Russian], Naukova Dumka, Kiev (1973).

S. S. D'yachenko,Formation of Austenite in Iron-Carbon Alloys [in Russian], Metallurgiya, Moscow (1982).

S. I. Mednikov and D. M. Gureev,Pis'ma Zh. Tekh. Fiz.,18, 25 (1992).

I. K. Kikoin,The Tables of Physical Quantities. A Reference Book [in Russian], Atomizdat, Moscow (1976).

V. I. Sindeev and G. A. Iskhakova,Fiz. Khim. Obrab. Mater., No. 2, 59 (1988).

D. M. Gureev,Kvantovaya Élektron.,25, 282 (1998).

Basics of the Physics and Technology of Ultrasound [in Russian], Nauka, Moscow (1987).

L. Ya. Popilov,A Reference Book of Electrical and Ultrasonic Methods for Treatment of Materials [in Russian], Mashgiz, Moscow (1963).

L. I. Mirkin,A Reference Book of X-Ray Diffraction Analysis of Polycrystals [in Russian], Fizmatgiz, Moscow (1961).

D. M. Gureev, S. I. Mednikov, S. V. Yamshchikov, and I. A. Balashov,Fiz. Khim. Obrab. Mater., No. 3, 109 (1993).

D. M. Gureev,Kvantovaya Élektron.,21, 810 (1994).

D. M. Gureev,Kvantovaya Élektron.,24, 338 (1997).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 1, 73 (1998).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 2, 41 (1998).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 1, 27 (1994).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 2, 102 (1994).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 1, 31 (1993).

D. M. Gureev, V. A. Evstratov, V. A. Katulin, et al.,Kvantovaya Élektron.,9, 815 (1982).

D. M. Gureev, V. K. Shukhostanov, and S. V. Yamshchikov,Fiz. Khim. Obrab. Mater., No. 6, 53 (1990).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 6, 139 (1994).

D. M. Gureev,Fiz. Khim. Obrab. Mater., No. 6, 126 (1994).

Author information

Authors and Affiliations

Additional information

Translated from a manuscript submitted October 23, 1998.

Rights and permissions

About this article

Cite this article

Gureev, D.M. Prospects for laser-ultrasonic treatment for surface modification, welding, and pattern cutting. J Russ Laser Res 20, 27–66 (1999). https://doi.org/10.1007/BF02508792

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02508792