Abstract

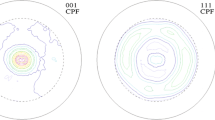

Through-thickness crystallographic texture, defect structure, and tensile embrittlement of 35 μm thick electrodeposit are characterized by successive thinning. An initially random grain structure, inherited from the substrate, evolves into a strong <220> fiber texture. The random to oriented grain transformation begins at the inception of thickening and is complete after about 15 μm deposit thickness, where about 0.9 volume fraction of grains become oriented near <220>. Further thickening of the deposit sharpens the texture, reducing the scatter around the <220> ideal orientation. A duplex coarse/fine particle (coherent domain) structure is obtained. Coarse particles along <220> are less defective and have smaller lattice strains; fine particles along <200>, presumably associated with the random grains, are defect-saturated with finely spaced twins, high dislocation density and enhanced lattice strains. With increasing distance from the shiny surface (of initial film formation), especially following the initial 10 μm deposit thickness, (a) along <220>: particle size and twin spacing increase whereas dislocation density and root mean square (rms) strains decrease, (b) along <200>: particle size increases gradually, dislocation density and rms strains increase sharply and the already fine twin spacing remains unchanged, and (c) the effective particle size ratio Deff<220>:Deff<200> exceeds 1.4, suggesting a twinning-induced z-direction particle shape anisotropy. A substantial decrease in tensile elongation is observed at 180°C. The embrittlement increases with the deposit thickness, attributed to the development of low density regions in the morphological boundaries. High elongation and embrittlement directional anisotropies are observed near the shiny surface, perhaps due to preferred nucleation on the substrate asperities.

Similar content being viewed by others

References

L.S. Palatnik and A.I. Il’inskii,Soviet Phys. Uspekhi 11, 564 (1969).

I.T. Aleksanyan, L.A. Tumanova and T.D. Shemargor,Phys. Met. Metall. 34 (3), 200 (1972).

N.A. Pangarov, S.D. Vitkova and I. Vzunova,Electrochim. Acta 11, 1747(1966).

N. Atanassov, S. Vitkova and S. Rashkov,Surf. Tech. 13,215 (1981).

I. Tomav,Mats. Sci. Forum 133–136, 175 (1993).

J. Bebczuk de Cusminsky,J. Cryst. Growth 41, 330 (1977).

H.D. Merchant,J. Electron. Mater. 22, 631 (1993).

L. G. Shultz,J. Appl. Phys. 20, 1030 (1949).

R. Junginger and G. Eisner,J. Electroch. Soc. 135, 2305 (1988).

E.M. Hofer and H.E. Hintermann,J. Electroch. Soc. 112,165 (1965).

D.E. Warren,X-ray Diffraction, (Reading, MA: Addison Wesley, 1969), p. 251.

D.B. Knorr, D.P. Tracy and T.M. Lu,Textures and Micro-structures 14–18, 543 (1991).

W.P. Chernock and P.A. Beck,J. Appl. Phys. 23, 341 (1952).

H.P. Klug and L.E. Alexander,X-Ray Diffraction Procedures, (New York: John Wiley, 1954).

D.B. Knorr,Mater. Res. Soc. Proc. 309, 75 (1993).

P. Ganesan, H.K. Kuo and R.J. DeAngelis,J. Catalysis 55, 310 (1978).

O.B. Girin, V.P. Khlyntsev and G.M. Vorobev,Russ. Met. (4) 172 (1988).

O.B. Girin,Russ. Met. (4) 130 (1990);Indus. Lab. 49, 55 (1983).

K. Lin and K.G. Sheppard,Plating Surf. Fin. 80, 40 (Aug. 1993).

T..Chen and P. Cavalotti,IEEE Trans. Magn. 18,1125(1982).

Y. Maeda,Jpn. J. Appl. Phys. Part 2, 24, L951 (1985).

N. Atanassov, S. Vitkova and S. Rashkov,Surf. Tech. 13,215 (1981).

C. Schmidt,Galvanotechnik 82, 3800 (1991).

E.A. Mamontov, L.A. Kurzbatova and A.P. Volenko,Soviet Electroch. 22, 589 (1986).

O.B. Girin and V.R. Khlyntsev,Russ. Met. (6) 151 (1990).

M. Froment and G. Maurin,J. Microsc. Spectrosc. Electron. 12, 379 (1987).

B. Grushko and G.R. Stafford,Scripta Metall. 23, 557, 1043 (1989);Metall. Trans. 20A, 1351 (1989); 21A, 2869 (1990).

V.G. Shadrow, A.V. Boltushkin and T.A. Tochitskit,Russ. Met. (4) 61 (1990).

V.V. Gubin et al.,Soviet Electroch. 20, 671 (1984).

K. Farrel and J.T. Houston,Metall. Trans, 1, 1979 (1970).

S. Nakahara and Y. Okinaka,Annu. Rev. Mater. Sci. 21, 93 (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

De Angelis, R.J., Knorr, D.B. & Merchant, H.D. Through-thickness characterization of copper electrodeposit. J. Electron. Mater. 24, 927–933 (1995). https://doi.org/10.1007/BF02652963

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02652963