Abstract

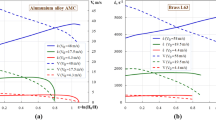

The nominally isothermal, uniaxial hot compression test has been analyzed with special reference to the effects of temperature nonuniformities and friction on sample deformation and flow stress estimates. A simple one-dimensional analysis was used to establish the influence of initial temperature nonuniformities, strain rate, and the temperature dependence of the flow stress on flow localization tendencies. Noticeable strain concentrations were predicted to occur only at high strain rates (∼10 s−1) in materials such as titanium alloys, but not in steels, for typical values of the initial temperature nonuniformity. More extensive numerical (finite element method) simulations of the compression test with various values of the friction shear factor corroborated the conclusions of the flow localization analysis. In addition, it was established that initial temperature nonuniformities, as well as friction, have an almost negligible effect on flow stress data deduced from measurements of average pressurevs true height strain, at least for reductions of the order of 50 pct. The analysis results were supported by observations of the deformation behavior of a near-gamma titanium aluminide and a low-alloy steel.

Similar content being viewed by others

Reference

G.E. Dieter:Workability Test Techniques, ASM, Metals Park, OH, 1984.

J.R. Newby:Metals Handbook, Volume 8: Mechanical Testing, 9th ed., ASM, Metals Park, OH, 1985.

T. Altan, S.I. Oh, and H.L. Gegel:Metal Forming: Fundamentals and Applications, ASM, Metals Park, OH, 1983.

J.J. Jonas and M.J. Luton: inAdvances in Deformation Processing, J.J. Burke and V. Weiss, eds., Plenum Press, New York, NY, 1978, pp. 215–43.

S.L. Semiatin and J.J. Jonas:Formability and Workability of Metals: Plastic Instability and Flow Localization, ASM, Metals Park, OH, 1984.

J.J. Jonas, R.A. Holt, and C.E. Coleman:Acta Metall., 1976, vol. 24, pp. 911–18.

C. G’sell, N.A. Aly-Helal, and J.J. Jonas:J. Mater. Sci., 1983, vol. 18, pp. 1731–42.

W.J. McG. Tegart:Ductility, ASM, Metals Park, OH, 1968, pp. 133–77.

C.M. Sellars and W.J. McG. Tegart:Int. Metall. Rev., 1972, vol. 17, pp. 1–24.

E. Rauch, G.R. Canova, J.J. Jonas, and S.L. Semiatin:Acta Metall., 1985, vol. 33, pp. 465–76.

S.L. Semiatin, N. Frey, C.R. Thompson, J.D. Bryant, S. El-Soudani, and R. Tisler:Scripta Metall. Mater., 1990, vol. 24, pp. 1403–08.

T.B. Nikander, S.L. Semiatin, and P.S. Raghupathi: Battelle, Columbus, OH, unpublished research, 1981.

S.L. Semiatin, E.W. Collings, V.E. Wood, and T. Altan:J. Eng. Ind., Trans. ASME, 1987, vol. 109, pp. 49–57.

P.R. Burte, S.L. Semiatin, and T. Altan:Proc. NAMRC XVIII, SME, Dearborn, MI, 1990, pp. 59–66.

S.L. Semiatin and G.D. Lahoti:Metall. Trans. A, 1981, vol. 12A, pp. 1705–17.

Author information

Authors and Affiliations

Additional information

S.I. OH, formerly Research Leader, Net Shape Manufacturing Group, Battelle Memorial Institute, Columbus, OH, 43201.

S.L. SEMIATIN, formerly Senior Research Scientist, Metalworking Group, Battelle Memorial Institute, Columbus, OH 43201.

Rights and permissions

About this article

Cite this article

Oh, S.I., Semiatin, S.L. & Jonas, J.J. An analysis of the isothermal hot compression test. Metall Trans A 23, 963–975 (1992). https://doi.org/10.1007/BF02675571

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02675571