Abstract

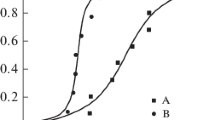

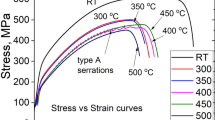

We present a large volume of unique experimental data on local fracture parameters and crack resistance characteristics of different structural alloys, including steels 15Kh2MFA and 15Kh2NMFA and their welded joints, subjected to different heat treatments, simulating exposure to different doses of radiation bombardment and used in manufacturing VVÉR-440 and VVÉR-1000 atomic reactor pressure vessels. These experimental results allow us to generalize the scientific conclusions concerning the scale effect in fracture mechanics, since they were obtained by investigating many materials (σ0.2 = 270–1500MPA) over a broad range of variation in specimen thickness (t=12.5–150 mm) and experimental temperature (T=77–573 K).

The data on the fracture toughness characteristics of a broad class of structural alloys suggest that the scale effect is complex and contradictory, depending first of all on the range of variation in the specimen thickness and the physicomechanical properties of the material, including those determined by the effect of production and service factors.

On the whole, the experimental data support the possibility noted in various literature sources that there are three different types of dependences of the fracture toughness on the specimen size (the fracture toughness can increase, decrease, or stay the same as the specimen size increases). It does not seem possible to predict and explain these dependences within approaches proposed earlier.

Similar content being viewed by others

References

F. G. Nelson, P. E. Schilling, and I. G. Kaufmann, “The effect of specimen size on the results of plane-strain fracture-toughness tests,” Eng. Fract. Mech.,4, No. 1, 33–50 (1972).

D. Munz, “The size effect of fracture toughness and the Irwin adjustment,” Int. J. Fract.,22, R17-R19 (1986).

I. G. Kaufman and F. G. Nelson, “More on specimen size in fracture toughness testing,” ASTM STP, No. 599, 74–85 (1974).

D. Munz, K. H. Galda, and F. Link, “Effect of specimen size on fracture toughness of a titanium alloy,” ASTM STP, No. 590, 219–234 (1976).

K. Markstrom, “On fracture toughness and its size dependence for steels showing thickness delamination,” Eng. Fract. Mech.,4, No. 4, 593–603 (1972).

H. P. Keller and D. Munz, “Effect of specimen size onJ-integral and stress intensity factor at the onset of crack extension,” ASTM STP, No. 631, 217–231 (1977).

G. S. Pisarenko, V. P. Naumenko, and G. S. Volkov, “Effect of strain constraint on fracture toughness of plastic steels,” Probl. Prochn., No. 11, 45–51 (1977).

J. C. Ritter, “Modified thickness criterion for fracture toughness testing,” Eng. Fract. Mech.,9, No. 3, 529–540 (1977).

W. Seidl, “Specimen size effect on the determination ofK Ic values in the range of elastic-plastic material behavior,” Eng. Fract. Mech.,12, No. 4, 581–597 (1979).

J. I. Bluhm, “A model for the effect of thickness on fracture toughness,” ASTM Proc., 61, 1324–1331 (1961).

D. Munz, “Minimum specimen size for the application of linear-elastic fracture mechanics,” ASTM STP, No. 668, 406–425 (1979).

C. Berger, H. P. Keller, and D. Munz, “Determination of fracture toughness with linear-elastic and elastic-plastic methods,” ASTM STP, No. 668, 378–405 (1979).

T. Ogata, K. Ishikawa, T. Yuri, et al., “Effects of specimen size, side-grooving and precracking temperature,” in: Adv. Cryog. Eng. Mater. [Proceedings, 7th Conference (ICMC), June 14–18, 1987],34, 259–266 (1988).

W. R. Andrews, V. Kumar, and M. M. Little, “Small-specimen brittle-fracture toughness testing,” ASTM STP, No. 743, 576–598 (1981).

C. M. Gilmore, V. Provenzano, F. A. Smidt, and J. R. Hawthorne, “Influence of thickness and temperature on stretched zone size specimens,” Met. Sci.,17, 177–185 (1983).

M. G. Daves, “Elastic-plastic fracture toughness based on the COD andJ-contour integral concepts,” ASTM STP, No. 668, 307–333 (1979).

N. B. Shaw and G. M. Spink, “The effect of temperature, specimen size and geometry on the fracture toughness of a 3PCT Ni−Cr−Mo−V low pressure turbine disc steel,” Met. Trans.,14A, 751–759 (1983).

B. Marandet, G. Philippeak, and G. Rousselier, “Effect of specimen size onJ Ic for a Ni−Cr−Mo rotor steel in the upper shelf region,” in: Adv. Fract. Res. [Preprints, Fifth International Confernece on Fracture, Cannes, 1981],2, 871–879 (1981).

P. De Roo, B. Marandet, G. Phelippeau, and G. Rousselier, “Effect of specimen dimensions on criticalJ-value at the onset of crack extension,” ASTM STP, No. 833, 604–621 (1984).

W. J. Wills, “Fracture toughness behavior of unirradiated and irradiated 2.25-Cr−1Mo steel plate and weldment,” Nucl. Technol.,64, No. 2, 175–185 (1984).

D.-Z. Sun, D. Dormagen, and W. Dahl, “Influence of specimen geometry on fracture mechanics values at the onset of stable crack extension,” Steel Res.,56, No. 8, 445–449 (1985).

G. P. Gibson, S. G. Druce, and C. E. Turner, “Effect of specimen size and geometry on ductile crack growth resistance in a Cr−Mn steel,” Int. J. Fract.,32, 219–240 (1987).

T. Iwadate, Y. Tanaka, S. Ono, and J. Watanale, “Analysis ofJ Ic measurement in transition region,” J. Soc. Mal. Sci.,1, No. 344, 430–436 (1982).

K. Machida, M. Kikushi, and H. Miyamoto, “The thickness effects of the side-grooved CCT specimens (fracture toughness of SUS 316 steel),” in: Proceedings, International Conference of Pressure Vessel Technology,5, 724–731 (1984).

S. G. Druce, “Effect of specimen geometry on the characterisation of ductile crack extension in C−Mn steel,” Adv. Fract. Res. [Preprint, Fifth International Conference on Fracture, Cannes],2, 843–854 (1981).

D. Sumamoto, M. Satoh, T. Funado, and M. Tomimatsu, “Specimen size effect onJ-integral fracture toughness,” in: Adv. Res. Strength and Fract. Mater. [Fourth International Conference on Fracture, Waterloo],3A, 267–272 (1977).

I. Milne and G. G. Chell, “Effect of size on theJ fracture criterion,” ASTM STP, No. 668, 358–377 (1979).

S. K. Putatunda, J. M. Rigsbee, and H. T. Corten, “Effect of size on elastic-plastic fracture toughness parameters,” J. of Test. and Eval., JTEVA,13, No. 3, 181–190 (1985).

G. W. Wellman, W. A. Sorew, R. H. Dodds, and S. T. Rolfe, “Specimen thickness effects for elastic-plastic CTOD toughness of an A36 steel,” WRC Bulletin, No. 328, 1–11 (1987).

T. Inghaw, J. T. Bland, and G. Wardle, “The influence of specimen size on the upper shelf toughness of SA 533-1 steel,” SMIRT 7, Chicago, August 1983, Paper G213, pp. 39–46.

K. Nagai, S. Shimizu, M. Iwadata, and S. Kawano, “The size effect on brittle fracture toughness under the large scale yielding,” Trans. Japan Welding Soc.,12, 14–18 (1981).

K. Wallin, “The size effect inK Ic results,” Eng. Fract. Mech.,22, No. 1, 149–163 (1985).

W. A. Sorem, R. H. Dodds, and S. T. Rolfe, “An analytical and experimental comparison of rectangular and square CTOD fracture specimens of an A36 steel,” Bulletin WPC, No. 328, 12–23 (1987).

F. Minami, M. Toyoda, and K. Satoh, “A probablistic analysis on thickness effect in fracture toughness,” Eng. Fract. Mech.,26, No. 3, 433–444 (1987).

V. T. Troshchenko, V. V. Pokrovskii, V. G. Kaplunenko et, al., “Effect of specimen size on the crack resistance of heat-resistant pressure-vessel steels,” Probl. Prochn., No. 10, 3–11 (1982).

V. T. Troshchenko, V. V. Pokrovskii, and V. G. Kaplunenko, “Effect of specimen size on the characteristic of cyclic crack resistance of heat-resistant steels. Communication 1,”Probl. Prochn., No. 4, 3–9 (1986).

V. V. Pokrovsky, V. T. Troschenko, V. G. Kaplunenko, et al., “A promising method for enhancing resistance of pressure vessels to brittle fracture,” Int. J. Press. Vess. and Piping,58, 9–24 (1994).

W. Dahl and V. Anton (eds.), Static Strength and Fracture Mechanics of Steels [Russian translation], Metallurgiya, Moscow (1986).

L. A. Kopel'man, Resistance of Weldments to Brittle Fracture [in Russian], Mashinostroenie, Leningrad (1987).

G. P. Karzov, B. Z. Margolin, and V. A. Shvetsova, “Some physicomechanical approaches to analysis of macroscopic fracture criteria. Communication, 3. Brittle fracture,” Probl. Prochn., No. 6, 7–14 (1989).

G. P. Karzov, B. Z. Margolin, A. A. Prus, and V. A. Shvetsova, “Analysis of brittle fracture initiation conditions,” Probl. Prochn., No. 11, 9–13 (1989).

G. P. Karzov, B. Z. Margolin, and V. A. Shvetsova, “Strain and mechanical criteria for brittle fracture,” in: Problems of Modern Fracture Mechanics [in Russian], Izdat. LGU, Leningrad (1990), pp. 102–121.

W. Dahl, D. Dormagen, and A. Halim, “Micromechanisms of fracture,” in: Proceedings, ECF6/Sixth Biennial European Conference on Fracture Control of Engineering Structures,6, 1467–1489 (1986).

K. Wallin, “The effect of ligament size on cleavage fracture toughness,” Eng. Fract. Mech.,32, No. 3, 449–457 (1989).

B. Faucher and W. R. Tyson, “A study of variability size and temperature effects on the fracture toughness of an arctic-grade steel plate,” ASTM, STP, No. 945, 164–178 (1988).

A. Bruckner-Foit, W. Ehl, D. Munz, and B. Trolldenier, “The size effect of microstructural implications of the weakest link model,” Fatig. Fract. Eng. Mat. Struct.,13, No. 3, 185–200 (1990).

D. Z. Sun, D. Dormagen, and W. Dahl, “Statistical characterization of fracture in the brittle-ductile transition regime of structural steels,” Steel Research,58, No. 1, 40–45 (1987).

H. Braam and J. Prij, “A statistical evaluation of the thickness effect of SENB4 using theJ distribution along the crack front,” in: Struct. Mech. React. Techn.: Transactions of the Ninth International Conference, Lausunna, 1987; (1987), Vol. G, pp. 33–38.

K. Wallin and K. Torronen, “Mechanisms based statistical requirements for fracture toughness testing,” in: Proceedings, ECF6 European Conference on Fracture Control of Engineering Structures (1986), pp. 563–575.

D. J. Naville and J. F. Knott, “Statistical distributions of toughness and fracture stress for homogeneous and inhomogeneous materials,” J. Mech. Phys. Solids,14, No. 3, 243–291 (1986).

B. Faucher and W. R. Tyson, “A statistical description of the effect of strain rate, thickness and temperature on the brittle fracture toughness of an arctic grade steel,” in: Proceedings, Eighth International Conference on Strength of Metals and Alloys, 1988 (ISMA 8); Vol. 3, pp. 1077–1082 (1989).

D. M. Shur, “Determination of the critical stress intensity factor from the specimen thickness-dependent nonlinearity tolerance of the stress—displacement diagram,” Zavod. Lab.,47, No. 1, 73–75 (1981).

A. Ya. Krasovskii, Brittleness of Metals at Low Temperatures [in Russian], Nauk. Dumka, Kiev (1980).

“Strength calculations and tests. Methods for mechanical tests of materials. Determination of the characteristics of crack resistance (fracture toughness) on static loading,” GOST 25.506-85, Izdat. Standartov, Moscow (1985).

S. Jun, D. Zengjie, and L. Zhounghua, “Effect of stress triaxiality in crack tip field on validity ofJ-dominance,” Eng. Fract. Mech.,34, No. 3, 637–643 (1989).

S. Jun, D. Zenjie, and L. Zhenghua, “Constraint intensity in crack tip field and elastic-plastic fracture criterion,” Eng. Fract. Mech.,34, No. 2, 413–418 (1989).

S. Jun, D. Zhengjie, L. Zhonghua, and T. Mingjing, “Stress triaxiality in crack tip regions of bend specimens with different crack-depth and fracture criterion at initiation,” Eng. Fract. Mech.,36, No. 2, 321–326 (1991).

J. W. Hancock and M. J. Cowling, “Role of state of stress in crack-tip failure processes,” Met. Sci.,14, 293–304 (1980).

J. W. Hancock and A. C. Mackenzie, “On the mechanism of ductile failure in high-strength steels subjected to multi-axial stress-states,” J. Mech. Phys. Solids.,24, 147–169 (1976).

J. R. Rice and D. M. Tracey, “On the ductile enlargement of voids in triaxial stress fields,”17, 201–217 (1969).

C. Q. Zheng and J. C. Radon, “The correlation of triaxial states of stress and the failure strain,” in: Proceedings, ICF International Symposium on Fracture Mechanics (Beijing); (1983), pp. 1057–1062.

V. R. Ranganath, A. N. Kumar, and R. K. Pandey, “Influence of notch tip state of stress on the fracture characteristics of a HSLA steel,” in: Proceedings of the International Conference on Mechanical Behavior of Materials. 5, Beijing, China (1988), 1, pp. 309–316.

D. Holland, A. Halim, and W. Dahl, “Influence of stress triaxiality upon ductile crack propagation,” Steel Res.,61, No. 10, 504–506 (1990).

V. G. Kaplunenko, “Technique for investigation of crack resistance of structural steel at the moment when a crack starts and stops,” Probl. Prochn., No. 10, 59–63 (1984).

V. T. Troshchenko, V. V. Pokrovskii, and P. V. Yasnii, “Effect of temperature on the crack resistance characteristics of steel with different strength levels,” Probl. Prochn., No. 9, 8–13 (1986).

V. T. Troshchenko, P. V. Yasnii, and V. V. Pokrovski, “Prediction of the effect of asymmetry of the loading cycle on the cyclic fracture toughness of structural alloys,” Probl. Prochn., No. 11, 20–25 (1985).

V. T. Troshchnko, V. V. Pokrovskii, V. G. Kaplunenko, and B. T. Timofeev, “Effect of specimen size and asymmetry of the cycle on the characteristics of unstable (jumpwise) crack propagation under cyclic loading,” Probl. Prochn., No. 3, 8–12 (1987).

V. V. Pokrovskii, V. G. Kaplunenko, Yu. L. Zvezdin, and B. T. Timofeev, “Effect of loading cycle asymmetry on the cyclic crack resistance characteristics of heat-resistant steels,” Probl. Prochn., No. 11, 8–13 (1987).

P. W. Bridgman, Studies in Large Plastic Flow and Fracture With Special Emphasis on the Effects of Hydrostatic Pressure [Russian translation], Izdat. Inostr. Lit., Moscow (1955).

P. Bowen and J. F. Knott, “Size effect on the microscopic cleavage fracture stress in martensitic microstructure,” Met. Trans.,17A, 231–241 (1986).

D. A. Curry, “Influence of hydrostatic tension on cleavage fracture of bainitic pressure vessel steel,” Met. Sci.,16, 435–440 (1982).

B. Z. Margolin, “Structural mechanics modeling of fracture of metallic materials and prediction of the durability of members of heavily loaded structures,” Dissertation in competition for the academic degree of Doctor of Technical Sciences, St. Petersburg (1992).

F. M. Beremin, “A local criterion for cleavage fracture of a nuclear pressure vessel steel,” Met. Trans.,14A, 2277–2286 (1983).

J. D. G. Groom and J. F. Knot, “Cleavage fracture in prestrained mild steel,” Met. Sci.,9, 390–400 (1975).

R. Sandstrom, G. Engberg, and Y. Bergstrom, “Influence of prestrain and strain aging on cleavage fracture in C—Mn-steel,” Met. Sci.,15, 401–412 (1981).

F. Mudry, “A local approach to cleavage fracture,” Nucl. Eng. and Design,105, No. 1, 65–76 (1987).

J. G. Sevillano, “Cleavage-limited maximum strength of work-hardened BCC polycrystals,” Acta Met.,24, No. 8, 1473–1485 (1986).

F. A. McClintock, “A criterion for ductile fracture by the growth of holes,” J. Appl. Mech., Trans. ASME, Ser. H.,25, 363–374 (1958).

B. Marini, F. Mudry, and A. Pineau, “Ductile rupture of A508 steel under nonradial loading,” Eng. Fract. Mech.,22, No. 3, 375–386 (1985).

Y. W. Shi, J. T. Barnby, and A. S. Nadkarni, “Estimation of stress triaxiality ahead of a notch by means of void growth studies,” in: Proceedings of the International Conference on Adv. Fracture Research, 6, ICF 6, New Delhi (1984), pp. 1329–1336.

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 5–25, January–February, 1997.

Rights and permissions

About this article

Cite this article

Troshchenko, V.T., Pokrovskii, V.V. & Kaplunenko, V.G. Prediction of crack resistance for heat-resistant steels taking into account the specimen size effect. Communication 1. Results of experimental investigations. Strength Mater 29, 1–15 (1997). https://doi.org/10.1007/BF02767570

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767570