Abstract

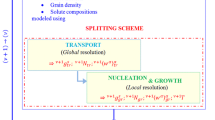

Modeling the development of micro- and macrosegregation patterns and grain structures in the equiaxed solidification of metal alloys under the combined influences of melt convection and the motion of free solid has been the subject of intense recent research efforts. This article presents a summary of selected experimental and theoretical studies aimed at understanding the convective transport processes both for a single grain and at the scale of a casting. The need for much additional research is emphasized.

Similar content being viewed by others

References

D.G. McCartney, “Grain Refining of Aluminum and Its Alloys Using Inoculants,”Int. Mat. Rev., 34 (1989), pp. 247–260.

M. Rappaz, “Modeling of Microstructure Formation in Solidification Processes,”Int. Mat. Rev., 34 (1989), pp. 93–123.

D.M. Stefanescu, “Critical Review of the Second Generation of Solidification Models for Castings: Macro Transport—Transformation,”Modeling of Casting, Welding and Advanced Solidification Processes VI (Warrendale, PA: TMS, 1993), pp. 3–20.

M. Rappaz and Ph. Thevoz, “Solute Diffusion Model for Equiaxed Dendritic Growth,”Acta Metall., 35 (1987), pp. 1487–1497.

C.J. Paradies et al., “The Effect of Flow Interactions with Dendritic Mushy Zones: A Model Experiment,”Modeling of Casting, Welding and Advanced Solidification Processes VI (Warrendale, PA: TMS, 1993), pp. 309–316.

J.A. Ortega and J. Beech, “Influence of Forced Convection on the Macrostructure of Aluminium and Aluminium-Copper Castings,”Modeling of Castiing VII (Warrendale, PA: TMS, 1995), pp. 117–125.

R. Zakhem, P.D. Weidman, and H.C. de Groh, III, “On the Drag of Model Dendrite Fragments at Low Reynolds Number,”Metall. Trans. A, 23A (1992), pp. 2169–2181.

S. Ahuja, M.S. thesis, University of Iowa, 1992.

R. Anaparti, M.S. thesis, University of Iowa, 1996.

H.C. de Groh III, et al., “Calculation of Dendrite Settling Velocity Using a Porous Envelope,”Metall. Trans. B, 24B (1993), pp. 749–753.

C.Y. Wang et al., “Multiparticle Interfacial Drag in Equiaxed Solidification,”Metall. Mater. Trans. B, 26B (1995), pp. 111–119.

D.R. Poirier and S. Ganesan, “Permeability for Flow of Interdendritic Liquid in Equiaxial Structures,”Mater. Sci. and Eng., A157 (1992), pp. 113–123.

A. Ramani, M.S. thesis, University of Iowa, 1995.

P.A. Agarwal, “Transport Phenomena in Multi-Particle Systems—II. Particle-Fluid Heat and Mass Transfer,”Chem. Sci. Eng., 43 (1988), pp. 2501–2510.

C.Y. Wang and C. Beckermann, “Equiaxed Dendritic Solidification with Convection. Part I. Multiscale/Multiphase Modeling,”Metall. Mat. Trans. A, 27A (1996), pp. 2754–2764.

W. Kurz and D.J. Fisher:Fundamentals of Solidification (Aedermannsdorf, Switzerland: Trans Tech, 1989).

R. Ananth and W.N. Gill, “Self-Consistent Theory of Dendritic Growth with Convection,”J. Crystal Growth, 108 (1991), pp. 173–189.

I.M. Krieger, “Rheology of Monodisperse Lattices,”Adv. Colloid Interf. Sci. B (1972), pp. 111–136.

L. Amberg, G. Chai, and L. Backerud, “Determination of Dendritic Coherency in Solidifying Melts by Rheological Measurements,”Mater. Sci. Eng., A173 (1993), pp. 101–103.

C. Beckermann and C.Y. Wang, “Multiphase/-scale Modeling of Alloy Solidification,”Annual Review of Heat Transfer VI (New York: Begell House, 1995), pp. 115–198.

C. Beckermann and C.Y. Wang, “Incorporation of Interfacial Phenomena in Solidification Models,”JOM, 46 (1994), pp. 42–47.

C. Beckermann and C. Y. Wang, “Equiaxed Dendritic Solidification with Convection, Part III. Comparisons with NH4Cl−H2O Experiments,”Metall. Mat. Trans. A, 27A (1996), pp. 2784–2795.

C.Y. Wang and C. Beckermann, “Equiaxed Dendritic Solidification with Convection, Part II. Numerical Simulations for an Al-4 Wt PctCu Alloy,”Metall. Mat. Trans. A, 27A (1996), pp. 2765–2783.

Additional information

C. Beckermann earned his Ph.D. in mechanical engineering at Purdue University in 1987. He is currently a professor at the University of Iowa. He is also a member of TMS.

Rights and permissions

About this article

Cite this article

Beckermann, C. Modeling segregation and grain structure development in equiaxed solidification with convection. JOM 49, 13–17 (1997). https://doi.org/10.1007/BF02914649

Issue Date:

DOI: https://doi.org/10.1007/BF02914649