Abstract

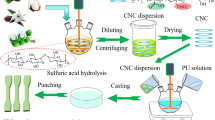

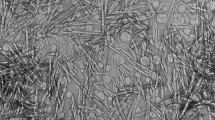

Low molecular weight poly(ethylene glycol) (PEG)-based polyurethane (PU)/cellulose nanocrystal (CNC) nanocomposites were prepared using in situ polymerization and pre-polymer approach. PEG was used as soft segment, and 1,4-butanediol (BDO) as chain extender and hexamethylene diisocyanate (HDI) were used as hard segment. Also, effect of CNC loading on different properties of the resulting nanocomposites such as microstructure, thermal properties, and microphase separation of soft and hard segments was investigated. Mechanical properties and shape memory behaviors were determined by tensile and shape memory tests, respectively. Due to low molecular weight of soft segment, the net effect of hydrogen bonding on different properties of nanocomposites is well investigated here. Results showed that introduction of CNCs into PU matrix influenced the hydrogen bonding between different moieties of structure, which resulted in different microphase separation states. Also, CNCs had no significant effect on thermophysical and thermal properties. However, tensile strength, elongation at break, and modulus as mechanical properties were affected significantly. Nanocomposites containing up to 0.5 wt.% of CNC had improved modulus, tensile strength, and elongation at break compared to neat PU, whereas higher amounts of CNC resulted in lower modulus, tensile strength, and elongation at break. Shape memory behaviors were evaluated using tensile test. Nanocomposites showed shape memory behavior up to 0.5 wt.% of CNCs, and at higher CNCs loading, no shape memory behavior was observed.

Similar content being viewed by others

References

R. Behnam, H. Roghani-Mamaqani, M. Salami-Kalajahi, Incorporation of silica nanoparticles and polyurethane into hybrid composites for increase of char residue. J. Therm. Anal. Calorim. 135, 3311–3319 (2019)

B.Q.Y. Chan, S.S. Liow, X.J. Loh, Organic-inorganic shape memory thermoplastic polyurethane based on polycaprolactone and polydimethylsiloxane. RSC Adv. 6, 34946–34954 (2016)

R. Behnam, H. Roghani-Mamaqani, M. Salami-Kalajahi, Preparation of carbon nanotube and polyurethane-imide hybrid composites by sol-gel reaction. Polym. Compos. 40, E1903–E1909 (2019)

G. Zheng, M. Lu, X. Rui, The effect of polyether functional polydimethylsiloxane on surface and thermal properties of waterborne polyurethane. Appl. Surf. Sci. 399, 272–281 (2017)

Z. Wu, H. Wang, X. Tian, P. Cui, X. Ding, X. Ye, The effects of polydimethylsiloxane on transparent and hydrophobic waterborne polyurethane coatings containing polydimethylsiloxane. Phys. Chem. Chem. Phys. 16, 6787–6794 (2014)

H. Nemati, H. Roghani-Mamaqani, M. Salami-Kalajahi, Preparation of polyurethane-acrylate and silica nanoparticle hybrid composites by a free radical network formation method. Bull. Mater. Sci. 42, 219 (2019)

F. Joki-Korpela, T.T. Pakkanen, Incorporation of polydimethylsiloxane into polyurethanes and characterization of copolymers. Eur. Polym. J. 47, 1694–1708 (2011)

M.M. Rahman, A. Hasneen, H.-D. Kim, W.K. Lee, Preparation and properties of polydimethylsiloxane (PDMS)/polytetramethyleneadipate glycol (PTAd)-based waterborne polyurethane adhesives: effect of pdms molecular weight and content. J. Appl. Polym. Sci. 125, 88–96 (2012)

M.M. Rahman, H.D.J. Kim, Characterization of waterborne polyurethane adhesives containing different soft segments. J. Adhesion Sci. Technol. 21, 81–96 (2007)

P. Khadivi, M. Salami-Kalajahi, H. Roghani-Mamaqani, Evaluation of in vitro cytotoxicity and properties of polydimethylsiloxane-based polyurethane/crystalline nanocellulose bionanocomposites. J. Biomed. Mater. Res. A 107, 1771–1778 (2019)

A. Pei, J.-M. Malho, J. Ruokolainen, Q. Zhou, L.A. Berglund, Strong nanocomposite reinforcement effects in polyurethane elastomer with low volume fraction of cellulose nanocrystals. Macromolecules 44, 4422–4427 (2011)

R.L.M. Sofla, M. Rezaei, A. Babaie, M. Nasiri, Preparation of electroactive shape memory polyurethane/graphene nanocomposites and investigation of relationship between rheology, morphology and electrical properties. Compos. Part B-Eng. 175, 107090 (2019)

M.V. Pergal, J. Nestorov, G. Tovilovic, S. Ostojic, D. Godevac, D. Vasiljevic-Radovic, J. Djonlagic, Structure and properties of thermoplastic polyurethanes based on poly(dimethylsiloxane): assessment of biocompatibility. J. Biomed. Mater. Res. A 102, 3951–3964 (2014)

R.L.M. Sofla, M. Rezaei, A. Babaie, Investigation of the effect of graphene oxide functionalization on the physical, mechanical and shape memory properties of polyurethane/reduced graphene oxide nanocomposites. Diamond Relat. Mater. 95, 195–205 (2019)

A. Babaie, M. Rezaei, R.L.M. Sofla, Investigation of the effects of polycaprolactone molecular weight and graphene content on crystallinity, mechanical properties and shape memory behavior of polyurethane/graphene nanocomposites. J. Mech. Behav. Biomed. Mater. 96, 53–68 (2019)

G. Pompe, A. Pohlers, P. Pötschke, J. Pionteck, Influence of processing conditions on the multiphase structure of segmented polyurethane. Polymer 39, 5147–5153 (1998)

J.R. Lin, L.W. Chen, Study on shape-memory behavior of polyether-based polyurethanes. I. Influence of the hard-segment content. J. Appl. Polym. Sci. 69, 1563–1574 (1998)

D.J. Martin, L.A. Poole Warren, P.A. Gunatillake, S.J. McCarthy, G.F. Meijs, K. Schindhelm, Polydimethylsiloxane/polyether-mixed macrodiol-based polyurethane elastomers: biostability. Biomaterials 21, 1021–1029 (2000)

Y.H. Lee, E.J. Kim, H.D. Kim, Synthesis and properties of waterborne poly(urethane urea)s containing polydimethylsiloxane. J. Appl. Polym. Sci. 120, 212–219 (2011)

K. Karl, G. Werner, Shape memory polymers. Angew. Chem. Int. Ed. 41, 2034–2057 (2002)

M.L. Auad, M.A. Mosiewicki, T. Richardson, M.I. Aranguren, N.E. Marcovich, Nanocomposites made from cellulose nanocrystals and tailored segmented polyurethanes. J. Appl. Polym. Sci. 115, 1215–1225 (2010)

F. Li, X. Zhang, J. Hou, M. Xu, X. Luo, D. Ma, B.K. Kim, Studies on thermally stimulated shape memory effect of segmented polyurethanes. J. Appl. Polym. Sci. 64, 1511–1516 (1997)

Y. Liu, K. Gall, M.L. Dunn, P. Mccluskey, Thermomechanical recovery couplings of shape memory polymers in flexure. Smart Mater. Struct. 12, 947–954 (2003)

A. Lendlein, A.M. Schmidt, R. Langer, AB-polymer networks based on oligo(Ɛ-caprolactone) segments showing shape-memory properties. Proc. Natl. Acad. Sci. U. S. A. 98, 842–847 (2001)

K. Gall, M.L. Dunn, Y. Liu, D. Finch, M. Lake, N.A. Munshi, Shape memory polymer nanocomposites. Acta Mater. 50, 5115–5126 (2002)

M.O. Seydibeyoglu, K. Oksman, Novel nanocomposites based on polyurethane and micro fibrillated cellulose. Compos. Sci. Technol. 68, 908–914 (2008)

Q.J. Wu, M. Henriksson, X. Liu, L.A. Berglund, A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromol 8, 3687–3692 (2007)

S.-A. Safavi-Mirmahalleh, M. Salami-Kalajahi, H. Roghani-Mamaqani, Effect of surface chemistry and content of nanocrystalline cellulose on removal of methylene blue from wastewater by poly(acrylic acid)/nanocrystalline cellulose nanocomposite hydrogels. Cellulose 26, 5603–5619 (2019)

M.L. Auad, V.S. Contos, S. Nutt, M.I. Aranguren, N.E. Marcovich, Characterization of nanocellulose reinforced shape memory Polyurethanes. Polym. Int. 57, 651–659 (2008)

J.F. Vincent, From cellulose to cell. J. Exp. Biol. 202, 3263–3268 (1999)

A.A. Septevani, D.A.C. Evans, P.K. Annamalai, D.J. Martin, The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crops Prod. 107, 114–121 (2017)

G. Mondragon, A. Santamaria-Echart, M.E.V. Hormaiztegui, A. Arbelaiz, C. Pena-Rodriguez, V. Mucci, M. Corcuera, M.I. Aranguren, A. Eceiza, Nanocomposites of waterborne polyurethane reinforced with cellulose nanocrystals from sisal fibres. J. Polym. Environ. 26, 1869–1880 (2018)

H.U. Ko, H.C. Kim, J.W. Kim, L. Zhai, T. Jayaramudu, J. Kim, Fabrication and characterization of cellulose nanocrystal based transparent electroactive polyurethane. Smart Mater. Struct. 26, 085012 (2017)

M. Haqani, H. Roghani-Mamaqani, M. Salami-Kalajahi, Synthesis of dual-sensitive nanocrystalline cellulose-grafted block copolymers of N-isopropylacrylamide and acrylic acid by reversible addition-fragmentation chain transfer polymerization. Cellulose 24, 2241–2254 (2017)

M. Haghayegh, G.M.M. Sadeghi, B. Shamayeli, Synthesis of shape memory polyurethane/nanoclay composites: chemical structure and interactions between polymer and nanoclay particles, Iran. J. Polym Sci. Technol. 25, 19–30 (2012)

Z. Abousalman-Rezvani, P. Eskandari, H. Roghani-Mamaqani, M. Salami-Kalajahi, Synthesis of coumarin-containing multi-responsive CNC-grafted and free copolymers with application in nitrate ion removal from aqueous solutions. Carbohydr. Polym. 225, 115247 (2019)

L. Noein, V. Haddadi-Asl, M. Salami-Kalajahi, Grafting of pH-sensitive poly (N, N-dimethylaminoethyl methacrylate-co-2-hydroxyethyl methacrylate) onto halloysite nanotubes via surface-initiated atom transfer radical polymerization for controllable drug release. Int. J. Polym. Mater. Polym. Biomater. 66, 123–131 (2017)

Z. Abousalman-Rezvani, P. Eskandari, H. Roghani-Mamaqani, H. Mardani, M. Salami-Kalajahi, Grafting light-, temperature, and CO2-responsive copolymers from cellulose nanocrystals by atom transfer radical polymerization for adsorption of nitrate ions. Polymer 182, 121830 (2019)

H. Zhang, J. Zhang, S. Song, G. Wu, J. Pu, Modified nanocrystalline cellulose from two kinds of modifiers used for improving formaldehyde emission and bonding strength of urea-formaldehyde resin adhesive. BioResources 6, 4430–4438 (2011)

C. Prisacariu, Polyurethane Elastomers (Springer, Berlin, 2011)

P. Panahian, M. Salami-Kalajahi, M.S. Hosseini, Synthesis of dual thermoresponsive and pH-sensitive hollow nanospheres by atom transfer radical polymerization. J. Polym. Res. 21, 455 (2014)

V. Kupka, Q. Zhou, F. Ansari, H. Tang, M. Slouf, L. Vojtova, L.A. Berglund, J. Janccar, Well-dispersed polyurethane/cellulose nanocrystal nanocomposites synthesized by a solvent-free procedure in bulk. Polym. Compos. 40, E456–E465 (2019)

I.M. Pereira, R.L. Orefice, Study of the morphology exhibited by linear segmented polyurethanes. Macromol. Symp. 299, 190–198 (2011)

V.W. Srichatrapimuk, S.L. Cooper, Infrared thermal analysis of polyurethane block polymers. Macromol. Sci. 15, 267–311 (1978)

N. Ren, Y. Song, C. Tao, B. Cong, Q. Cheng, Y. Huang, G. Xu, J. Bao, Effect of the soft and hard segment composition on the properties of waterborne polyurethane-based solid polymer electrolyte for lithium ion batteries. J. Solid State Electrochem. 22, 1109–1121 (2017)

D. Pedrazzoli, I. Manas-Zloczower, Understanding phase separation and morphology in thermoplastic polyurethanes nanocomposites. Polymer 90, 256–263 (2016)

N. Akram, K.M. Zia, M. Saeed, A. Mansha, W.G. Khan, Morphological studies of polyurethane based pressure sensitive adhesives by tapping mode atomic force microscopy. J. Polym. Res. 25, 194 (2018)

M. Song, H.S. Xia, K.J. Yao, D.J. Hourston, A study on phase morphology and surface properties of polyurethane/organoclay nanocomposites. Eur. Polym. J. 41, 259–266 (2005)

M. Golshan, M. Salami-Kalajahi, H. Roghani-Mamaqani, M. Mohammadi, Poly(propylene imine) dendrimer-grafted nanocrystalline cellulose: doxorubicin loading and release behavior. Polymer 117, 287–294 (2017)

A. Pirayesh, M. Salami-Kalajahi, H. Roghani-Mamaqani, E. Dehghani, Investigation of thermophysical and adhesion/mechanical properties of amine-cured epoxidized polysulfide polymer/epoxidized graphene nanocomposites. Prog. Org. Coat. 131, 211–218 (2019)

S. Moqadam, M. Salami-Kalajahi, M. Mahdavian, Synthesis and characterization of sunflower oil-based polysulfide polymer/cloisite 30B nanocomposites, Iran. J. Chem. Chem. Eng. 37, 185–192 (2018)

R. Cha, Z. He, Y. Ni, Preparation and characterization of thermal/pH-sensitive hydrogel from carboxylated nanocrystalline cellulose. Carbohydr. Polym. 88, 713–718 (2012)

A. Bahadur, A. Saeed, S. Iqbal, M. Shoaib, M.S.U. Rahman, M.I. Bashir, M. Asghar, M.A. Ali, T. Mahmood, Biocompatible waterborne polyurethane-urea elastomer as intelligent anticancer drug release matrix: a sustained drug release study. React. Funct. Polym. 119, 57–63 (2017)

A. Abbasi, G.M.M. Sadeghi, I. Ghasemi, M. Shahrousvand, Shape memory performance of green in situ polymerized nanocomposites based on polyurethane/graphene nanoplatelets: synthesis, properties, and cell behavior. Polym. Compos. 39, 4020–4033 (2018)

F.K. Molavi, I. Ghasemi, M. Messori, M. Esfandeh, Nanocomposites based on poly(L-lactide)/poly(ε-caprolactone) blends with triple-shape memory behavior: effect of the incorporation of graphene nanoplatelets (GNps). Compos. Sci. Technol. 151, 219–227 (2017)

A. Saralegi, M.L. Gonzalez, A. Valea, A. Eceiza, M.A. Corcuera, The role of cellulose nanocrystals in the improvement of the shape-memory properties of castor oil-based segmented thermoplastic polyurethanes. Compos. Sci. Technol. 92, 27–33 (2014)

M.S. Kim, J.K. Jun, H.M. Jeong, Shape memory and physical properties of poly(ethyl methacrylate)/Na-MMT nanocomposites prepared by macroazoinitiator intercalated in Na-MMT. Compos. Sci. Technol. 68, 1919–1926 (2008)

A.E. Kalajahi, M. Rezaei, F. Abbasi, G.M.M. Sadeghi, The effect of chain extender type on the physical, mechanical and shape memory properties of poly (ε-caprolactone)-based polyurethane-ureas. Polym.-Plast. Technol. Eng. 56, 1977–1985 (2017)

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khadivi, P., Salami-Kalajahi, M., Roghani-Mamaqani, H. et al. Fabrication of microphase-separated polyurethane/cellulose nanocrystal nanocomposites with irregular mechanical and shape memory properties. Appl. Phys. A 125, 779 (2019). https://doi.org/10.1007/s00339-019-3082-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-3082-y