Abstract

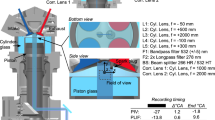

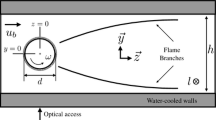

This paper shows the results of spatially resolved temperature measurements of the piston surface of an optically accessible direct injection spark ignition engine during flame impingement. High-speed thermographic phosphor thermometry (TPT), using Gd3Ga5O12:Cr,Ce, and planar laser-induced fluorescence of the hydroxyl radical (OH-PLIF) were used to investigate the temperature increase and the time and position of flame impingement at the piston surface. Measurements were conducted at two operating cases and showed heating rates of up to 16,000 K/s. The OH-PLIF measurements were used to localize flame impingement and calculate conditioned statistics of the temperature profiles. The TPT coating was characterized and its influence on the temperature measurements evaluated.

Similar content being viewed by others

Abbreviations

- CA50%:

-

Crank angle degree where 50% of the heat is released

- CAD:

-

Crank angle degree

- CADdQmax :

-

Crank angle degree of maximum heat release

- CADPmax :

-

Crank angle degree of maximum pressure

- CMOS:

-

Complementary metal–oxide–semiconductor

- COV:

-

Coefficient of variation

- FWHM:

-

Full width half maximum

- HCCI:

-

Homogeneous charge compression ignition

- IC:

-

Internal combustion

- IMEP:

-

Indicated mean effective pressure

- PLIF:

-

Planar laser-induced fluorescence

- OH:

-

Hydroxyl radical

- Std:

-

Standard deviation

- TPT:

-

Thermographic phosphor thermography

- UV:

-

Ultraviolet

- a:

-

Thermal diffusivity

- Bi:

-

Biot number

- cp :

-

Heat capacity

- ∆T :

-

Temperature difference

- Fo :

-

Fourier number

- k:

-

Heat conductivity

- L:

-

Length

- p:

-

Pressure

- t:

-

Time

- α:

-

Heat transfer coefficient

- δ:

-

Thickness

- λ:

-

Air/fuel ratio

- μ:

-

Absorption coefficient

- ρ:

-

Density

- abs:

-

Absorption

- c:

-

Coating

- g:

-

Gas

References

S.W. Allison, G.T. Gillies, Rev. Sci. Instrum. 68, 2615 (1997)

J. Brübach, C. Pflitsch, A. Dreizler, B. Atakan, Prog. Energy Combust. Sci. 39, 37 (2013)

J.S. Armfield, R.L. Graves, D.L. Beshears, M.R. Cates, T.V. Smith, S.W. Allison, Phosphor thermometry for internal combustion engines, in: International Spring Fuels & Lubricants Meeting & Exposition (SAE International400 Commonwealth Drive, Warrendale, PA, United States 1997)

C. Wilhelmsson, A. Vressner, P. Tunestål, B. Johansson, G. Särner, M. Aldén, Combustion chamber wall temperature measurement and modeling during transient HCCI operation, in: Powertrain & Fluid Systems Conference & Exhibition (SAE International 2005)

T. Aizawa, H. Kosaka, SAE Int. J. Fuels Lubr. 1, 549 (2009)

M. Aldén, A. Omrane, M. Richter, G. Särner, Prog. Energy Combust. Sci. 37, 422 (2011)

N. Fuhrmann, C. Litterscheid, C.-P. Ding, J. Brübach, B. Albert, A. Dreizler, Appl. Phys. B 116, 293 (2014)

J.T. Kashdan, G. Bruneaux, Laser-induced phosphorescence measurements of combustion chamber surface temperature on a single-cylinder diesel engine, in: SAE International Powertrains, Fuels and Lubricants Meeting (SAE International 2011)

K. Fukui, Y. Wakisaka, K. Nishikawa, Y. Hattori, H. Kosaka, A. Kawaguchi, Development of instantaneous temperature measurement technique for combustion chamber surface and verification of temperature swing concept, in: SAE 2016 World Congress and Exhibition (SAE International 2016)

N. Fuhrmann, M. Schneider, C.-P. Ding, J. Brübach, A. Dreizler, Meas. Sci. Technol. 24, 095203 (2013)

H. Becker, A. Arnold, R. Suntz, P. Monkhouse, J. Wolfrum, R. Maly, W. Pfister, Appl. Phys. B 50, 473 (1990)

C.F. Kaminski, J. Hult, M. Aldén, Appl. Phys. B. 68, 757 (1999)

J.D. Miller, M. Slipchenko, T.R. Meyer, N. Jiang, W.R. Lempert, J.R. Gord, Opt. Lett. 34, 1309 (2009)

S.H.R. Müller, B. Böhm, M. Gleißner, S. Arndt, A. Dreizler, Appl. Phys. B 100, 447 (2010)

C. Knappe, M. Algotsson, P. Andersson, M. Richter, M. Tunér, B. Johansson, M. Aldén, Combust. Flame 160, 1466 (2013)

B. Atakan, D. Roskosch, Proc. Combust. Inst. 34, 3603 (2013)

E. Baum, B. Peterson, B. Böhm, A. Dreizler, Flow Turbul. Combust. 92, 269 (2014)

J. Brübach, J. Janicka, A. Dreizler, Optics Lasers Eng. 47, 75 (2009)

VDI-Wärmeatlas, (Springer, Berlin, 2013)

G.P. Merker, C. Schwarz, Grundlagen Verbrennungsmotoren. (Vieweg + Teubner, Wiesbaden, 2009)

Acknowledgements

The authors gratefully acknowledge the financial support of the DFG (Deutsche Forschungsgemeinschaft) project DR 374/7 − 2 and the Gottfried Wilhelm Leibniz program. The support of Prof. Albert and the Eduard-Zintl-Institut für Anorganische und Physikalische Chemie, Technische Universität Darmstadt, in determining the thermographic phosphor properties, is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

This section explains the post-processing steps undertaken to determine the flame impingement at the piston surface. The post-processing was done using MATLAB. Figure 10 shows the results of the flame position detection for an example cycle. The three displayed images are recordings of the flame and show the recorded OH-PLIF signal after the background subtraction. The white line highlights the flame position, which was determined using the following sequence of processing steps.

After subtracting the background image, a median filter (17 pixels) was used to remove noise. To remove the remaining background intensity, which gradually changes along the laser path, the median intensity of each pixel row was subtracted. In the first frame in Fig. 10, a signal can be seen at the position where the piston surface is located. This is the phosphorescence signal of the phosphor coating and, for some cycles in which beam steering effects were strong, this signal disturbed the robust detection of the flame position. To remove this signal, the number of each pixel from shortly above the piston was compared with the number of pixels above it. If the counts were higher than at the pixel above, the counts for that pixel were set to the same value, ensuring a monotonic intensity decay from shortly above the piston until the piston. The flame front was then determined, using the maximum gradient in y-direction. To avoid flame detection in every pixel row, a threshold for the minimum gradient was used. High absorption and beam steering effects prevented robust detection of the flame front in some cases; a conservative threshold was set so that no flame impingement was detected when there was none.

After the flame position was determined, it was compared with the flame position in the previous frame. Areas of new flame impingement regions were selected and cropped from the side by 20 pixels to inhibit the evaluation of very small regions. In the remaining regions, the temperature determined by thermographic phosphor thermometry was evaluated for the conditioned analysis. It is assumed that, for the selected flame impingement events, the moment of flame impingement occurred in between the two frames at which the flame impinged the piston (therefore 0.75 CAD before the time at which the image used for flame impingement detection was recorded).

Rights and permissions

About this article

Cite this article

Ding, CP., Honza, R., Böhm, B. et al. “Simultaneous measurement of flame impingement and piston surface temperatures in an optically accessible spark ignition engine”. Appl. Phys. B 123, 110 (2017). https://doi.org/10.1007/s00340-017-6694-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-017-6694-y