Abstract

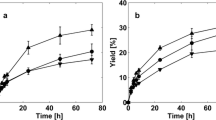

A self-designed horizontal rotating bioreactor (HRR) was applied for enzymatic hydrolysis of pretreated corn stover to improve the process economics of ethanol production. The mixing principle was based on gravity and free fall employed with tank-rotating. The liquefaction performances using the HRR and the vertical stirred-tank reactor (VSTR) with a helical impeller were compared and analyzed by measuring rheological properties of the slurry. During the enzymatic hydrolysis, viscosity decreased dramatically in the initial phase for both bioreactors and more pronouncedly for the HRR. Rheological parameters fitted to the power law showed that shear thinning properties of the slurry weakened during the reaction. The glucose concentration was used to define the efficiency of the saccharification reaction. The HRR also proved to be more efficient for glucose release with both the constant and fed-batch substrate addition modes. Liquefaction and saccharification at 25 % w/w dry matter (DM) and enzyme loading of 7 FPU/g DM resulted in the optimal glucose concentration of 86 g/kg. Results revealed a decrease in cellulose conversion at increasing initial DM, which was slighter in the HRR compared with that in the VSTR.

Similar content being viewed by others

References

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Yang J, Zhang X, Yong Q, Yu S (2010) Three-stage hydrolysis to enhance enzymatic saccharification of steam-exploded corn stover. Bioresour Technol 101(13):4930–4935

Wyman CE (2007) What is (and is not) vital to advancing cellulosic ethanol. Trends Biotechnol 25(4):153–157

Stickel JJ, Knutsen JS, Liberatore MW, Luu W, Bousfield DW, Klingenberg DJ, Scott CT, Root TW, Ehrhardt MR, Monz TO (2009) Rheology measurements of a biomass slurry: an inter-laboratory study. Rheol Acta 48(9):1005–1015

Wingren A, Galbe M, Zacchi G (2003) Techno-economic evaluation of producing ethanol from softwood: comparison of SSF and SHF and identification of bottlenecks. Biotechnol Prog 19(4):1109–1117

Jorgensen H, Vibe-Pedersen J, Larsen J, Felby C (2007) Liquefaction of lignocellulose at high-solids concentrations. Biotechnol Bioeng 96(5):862–870. doi:10.1002/bit.21115

Hodge DB, Karim MN, Schell DJ, McMillan JD (2009) Model-based fed-batch for high-solids enzymatic cellulose hydrolysis. Appl Biochem Biotechnol 152(1):88–107

Mohagheghi A, Tucker M, Grohmann K, Wyman C (1992) High solids simultaneous saccharification and fermentation of pretreated wheat straw to ethanol. Appl Biochem Biotechnol 33(2):67–81. doi:10.1007/bf02950778

Knutsen JS, Liberatore MW (2009) Rheology of high-solids biomass slurries for biorefinery applications. J Rheol 53(4):877. doi:10.1122/1.3143878

De Bari I, Viola E, Barisano D, Cardinale M, Nanna F, Zimbardi F, Cardinale G, Braccio G (2002) Ethanol production at flask and pilot scale from concentrated slurries of steam-exploded aspen. Ind Eng Chem Res 41(7):1745–1753. doi:10.1021/ie010571f

Varga E, Klinke HB, Réczey K, Thomsen AB (2004) High solid simultaneous saccharification and fermentation of wet oxidized corn stover to ethanol. Biotechnol Bioeng 88(5):567–574

Roche CM, Stickel JJ (2009) High-solids enzymatic saccharification screening method for lignocellulosic biomass. Paper presented at the 31st symposium on biotechnology for fuels and chemicals, San Francisco

Fan Z, South C, Lyford K, Munsie J, van Walsum P, Lynd LR (2003) Conversion of paper sludge to ethanol in a semicontinuous solids-fed reactor. Bioprocess Biosyst Eng 26(2):93–101. doi:10.1007/s00449-003-0337-x

Humbird D, Davis R, Tao L, Kinchin C, Hsu D, Aden A (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol. NREL/TP-5100-47764. National renewable energy laboratory

Larsen J, Haven MØ, Thirup L (2012) Inbicon makes lignocellulosic ethanol a commercial reality. Biomass Bioenergy 46:36–45

Ehrhardt M, Monz T, Root T, Connelly R, Scott C, Klingenberg D (2010) Rheology of dilute acid hydrolyzed corn stover at high solids concentration. Appl Biochem Biotechnol 160(4):1102–1115

González Quiroga A, Costa A, Maciel Filho R (2010) Analysis of conversion and operation strategies for enzymatic hydrolysis of lignocellulosic biomass in a series of CSTRs with distributed feeding. Bioprocess Biosyst Eng 33(8):901–910. doi:10.1007/s00449-010-0413-y

Borden JR, Lee YY, Yoon HH (2000) Simultaneous saccharification and fermentation of cellulosic biomass to acetic acid. Appl Biochem Biotechnol 84(1):963–970

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87–112

Kristensen J, Felby C, Jørgensen H (2009) Determining Yields in High Solids Enzymatic Hydrolysis of Biomass. Appl Biochem Biotechnol 156(1–3):127–132. doi:10.1007/s12010-008-8375-0

Dasari RK, Dunaway K, Berson RE (2008) A scraped surface bioreactor for enzymatic saccharification of pretreated corn stover slurries. Energy Fuels 23(1):492–497

Negro MJ, Manzanares P, Ballesteros I, Oliva JM, Cabañas A, Ballesteros M (2003) Hydrothermal pretreatment conditions to enhance ethanol production from poplar biomass. Appl Biochem Biotechnol 105(1):87–100

Rosgaard L, Andric P, Dam-Johansen K, Pedersen S, Meyer AS (2007) Effects of Substrate Loading on Enzymatic Hydrolysis and Viscosity of Pretreated Barley Straw. Appl Biochem Biotechnol 143(1):27–40. doi:10.1007/s12010-007-0028-1

Sørensen HR, Pedersen S, Meyer AS (2008) Optimization of reaction conditions for enzymatic viscosity reduction and hydrolysis of wheat arabinoxylan in an industrial ethanol fermentation residue. Biotechnol Prog 22(2):505–513

Pimenova NV, Hanley TR (2003) Measurement of rheological properties of corn stover suspensions. Appl Biochem Biotechnol 106(1):383–392

Zhang J, Chu D, Huang J, Yu Z, Dai G, Bao J (2010) Simultaneous saccharification and ethanol fermentation at high corn stover solids loading in a helical stirring bioreactor. Biotechnol Bioeng 105(4):718–728. doi:10.1002/bit.22593

Lenting H, Warmoeskerken M (2001) Mechanism of interaction between cellulase action and applied shear force, an hypothesis. J Biotechnol 89(2):217–226

Gruno M, Valjamae P, Pettersson G, Johansson G (2004) Inhibition of the Trichoderma reesei cellulases by cellobiose is strongly dependent on the nature of the substrate. Biotechnol Bioeng 86(5):503–511. doi:10.1002/bit.10838

Knutsen JS, Liberatore MW (2010) Rheology modification and enzyme kinetics of high solids cellulosic slurries. Energy Fuels 24(5):3267–3274. doi:10.1021/ef100140g

Mais U, Esteghlalian AR, Saddler JN, Mansfield SD (2002) Enhancing the enzymatic hydrolysis of cellulosic materials using simultaneous ball milling. Appl Biochem Biotechnol 98(1):815–832

Kristensen JB, Felby C, Jørgensen H (2009) Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 2(1):11. doi:10.1186/1754-6834-2-11

Schwald W, Breuil C, Brownell H, Chan M, Saddler J (1989) Assessment of pretreatment conditions to obtain fast complete hydrolysis on high substrate concentrations. Appl Biochem Biotechnol 20(1):29–44

Cara C, Moya M, Ballesteros I, Negro MJ, González A, Ruiz E (2007) Influence of solid loading on enzymatic hydrolysis of steam exploded or liquid hot water pretreated olive tree biomass. Process Biochem 42(6):1003–1009

Hodge DB, Karim MN, Schell DJ, McMillan JD (2008) Soluble and insoluble solids contributions to high-solids enzymatic hydrolysis of lignocellulose. Bioresour Technol 99(18):8940–8948

Panagiotou G, Olsson L (2006) Effect of compounds released during pretreatment of wheat straw on microbial growth and enzymatic hydrolysis rates. Biotechnol Bioeng 96(2):250–258

Pan X (2008) Role of functional groups in lignin inhibition of enzymatic hydrolysis of cellulose to glucose. J Biobased Mater Bio 2(1):25–32

Chandra RP, Au-Yeung K, Chanis C, Roos AA, Mabee W, Chung PA, Ghatora S, Saddler JN (2010) The influence of pretreatment and enzyme loading on the effectiveness of batch and fed-batch hydrolysis of corn stover. Biotechnol Prog. doi:10.1002/btpr.508

Acknowledgments

This work was funded by the National Natural Science Foundation of China (No. 20876078), the Key Program of the National Natural Science Foundation of China (No. 20936002), the United Foundation of NSFC and Guangdong Province (No. U0733001), the National Hi-Tech Research and Development Program of China (No. 2009AA02Z208), the National Key Technology Support Program of China) (2011BAD23B03), Research of arachidonic acid production of Mortierella alpina based on metabonomics (No.21176124).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, J., Zhang, F., Li, Y. et al. Enzymatic liquefaction and saccharification of pretreated corn stover at high-solids concentrations in a horizontal rotating bioreactor. Bioprocess Biosyst Eng 37, 173–181 (2014). https://doi.org/10.1007/s00449-013-0983-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-0983-6