Abstract

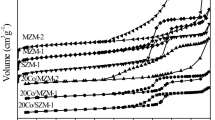

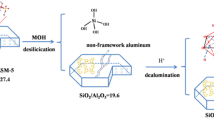

ZSM-5 monolith foam (ZMF) samples with various framework Si/Al ratios have been successfully synthesized by polyurethane foam (PUF) template method and evaluated for their catalytic performance towards methanol to propylene (MTP) reaction. The samples were tested for their textural properties using SEM, XRD, BET surface area, pore volume and NH3-TPD techniques revealing the formation of ZMF exhibiting about 100–300 μm range macro pores created by packed assembly of 5 μm size orthorhombic shaped ZSM-5 crystals. The ZMF samples exhibited effective activity in methanol to olefin conversion, with superior product selectivities at optimum Si/Al ratio of 250. Further, the ZMF catalyst with high macro porosity exhibited superior catalytic activity compared to its pelletized form, especially at higher feed flow rates, that signifies the importance of macro porous structure of ZMF in facilitating the enhanced mass transport for the labile diffusion of light olefins. Reaction temperature also played a vital role in determining product selectivity. At 500 °C, the catalysts exhibited the highest light olefin (C2 =–C4 =) selectivity and above this temperature, formation of C5 + is prevailed at the cost of C2 =–C4 = revealing the accelerated occurrence of oligomerization reactions at these conditions. At optimized catalytic properties and reaction conditions, the catalyst exhibited as high as 75% selectivity to C2–C4 olefins, with propylene as major component (~44%).

Similar content being viewed by others

References

Brogen M, Svelle S, Joensen F, Nerlov J, Kolboe S, Bonino F, Palumbo L, Bordiga S, Olsbye U (2007) J Catal 249:195

Keil FJ (1999) Micropor Mesopor Mater 339:36

Chen JQ, Bozzano A, Glover B, Fuglerud T, Kvisle S (2005) Catal Today 106:103

Stocker M (1999) Micropor Mesopor Mater 29:3

Zhu Q, Hinode M, Yokoi T, Kondo JN, Kubota Y, Tatsumi T (2008) Micropor Mesopor Mater 116:253

Cui Z-M, Liu Q, Ma Z, Bian S-W, Song W-G (2008) J Catal 258:83

Patcas FC (2005) J Catal 231:194

Shan Z, van Kooten WEJ, Oudshoorn OL, Jansen JC, van Bekkum H, van den Bleek CM, Calis HPA (2000) Micropor Mesopor Mater 34:81

Davis SP, Borgstedt EVR, Suib SL (1990) Chem Mater 2:712

Boudreau LC, Kuck JA, Tsapatsis M, Membr J (1999) Science 152:41

Hedlund J, Noack M, Kölsch P, Creaser D, Caro J, Sterte J (1999) J Membr Sci 159:263

Bein T (1996) Chem Mater 8:1636

Caro J, Noack M, Kölsch P, Schäfer R (2000) Micropor Mesopor Mater 38:3

Kormarneni S, Katsuki H, Furuta SJ (1998) Mater Chem 8:2327

Zampieri A, Colombo P, Mabande GTP, Selvam T, Schwieger W (2004) Adv Mater 16:819

Wine G, Tessonnier J-P, Rigolet S, Marichal C, Ledoux M-J, Huu C-P (2006) J Mol Catal A 248:113

Seijger GBF, Oudshoorn OL, van Kooten WEJ, Jansen JC, van Bekkum H, van den Bllek CM, Calis HPA (2000) Micropor Mesopor Mater 39:195

Anderson MW, Holmes SM, Hanif N, Cundy CS (2000) Angew Chem Int Ed 39:2707

Zhang B, Davis SA, Mendelson NH, Mann S (2000) Chem Commun 781

Holland BT, Abrams L, Stein A (1999) J Am Chem Soc 121:4308

Tosheva L, Valtchev V, Sterte J (2000) Micropor Mesopor Mater 35–36:621

Valtchev V, Schoeman BJ, Hedlund J, Mintova S, Sterte J (1996) Zeolites 17:408

Ha K, Lee Y-J, Jung D-Y, Lee JH, Yoon KB (2000) Adv Mater 12:1614

Huang L, Wang Z, Sun J, Miao L, Li Q, Yan Y, Zhao D (2000) J Am Chem Soc 122:3530

Lee YJ, Lee JS, Park YS, Yoon KB (2001) Adv Mater 13:1259

Lee YJ, Yoon KB (2006) Micropor Mesopor Mater 88:176

Kim WJ, Kim TJ, Ahn WS, Lee YJ, Yoon KB (2003) Catal Lett 91:123

Acknowledgments

The authors would like to acknowledge funding from the Korea Ministry of Knowledge Economy (MKE) through ‘‘Project of next-generation novel technology development’’ of ITEP. Dr. N. Viswanadham is thankful to Korea Federation of Science & Technology (KOSEF) for giving Brain-Pool fellowship.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lee, YJ., Kim, YW., Jun, KW. et al. Textural Properties and Catalytic Applications of ZSM-5 Monolith Foam for Methanol Conversion. Catal Lett 129, 408–415 (2009). https://doi.org/10.1007/s10562-008-9811-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9811-z