Abstract

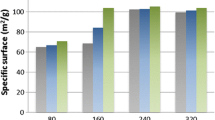

The production of high filler-loaded recycled papers is often affected by high values of linting and low values of strength. In the first case, the accumulation of lint particles from paper’s surface on the printing blanket affects the quality of the printed paper and the pressroom’s productivity. In the second case, increasing the use of fillers and recycling cycles lead to poor paper strength. Cellulose nanofibers (CNFs) are receiving a great deal of attention due to their potential as a reinforcement aid for high filler-loaded papers through filler–fiber interaction and interfiber bonding. It is already proven that high quality CNFs can reduce linting, although their industrial application is limited by their high production cost. The objective of this research is, therefore, to quantify the effect of applying lower grade, more sustainable CNFs on linting phenomena and on the mechanical properties of recycled papers. Eucalyptus, pine and triticale residues were used as cellulose sources, and the CNFs were produced minimizing the chemical pretreatment before homogenization. Addition of 3 wt% of CNFs from pine residues into the recycled paper with 15.7 wt% of total filler reduced linting by 40% and increased tensile strength by 15.1%; further improvements on linting and mechanical properties were achieved at 5 wt%. Moreover, the increase in drainage time can be overcome by the addition of a retention aid, in this case a coagulant-cationic polyacrylamide-bentonite system, commonly used in paper mills.

Similar content being viewed by others

References

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99:1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029

Amiri R, Begin B, Deshaies S, Mozaffari S (2004) Effects of wood and pulp quality on linting propensity. Pulp Paper Can 105:23–29

Aspler J, Jong J, Manfred T (2012) Benchmarking paper machine influence on linting and piling. J Sci Technol For Prod Process 2:32–39

Balea A, Blanco A, Merayo N, Negro C (2016a) Effect of nanofibrillated cellulose to reduce linting on high filler-loaded recycled papers. Appita J 69:148–156

Balea A, Blanco A, Monte MC, Merayo N, Negro C (2016b) Effect of bleached eucalyptus and pine cellulose nanofibers on the physico-mechanical properties of cartonboard. BioResources 11:8123–8138. https://doi.org/10.15376/biores.11.4.8123-8138

Balea A, Merayo N, Fuente E, Delgado-Aguilar M, Mutje P, Blanco A, Negro C (2016c) Valorization of corn stalk by the production of cellulose nanofibers to improve recycled paper properties. BioResources 11:3416–3431

Balea A, Merayo N, Fuente E, Negro C, Blanco A (2016d) Assessing the influence of refining, bleaching and TEMPO-mediated oxidation on the production of more sustainable cellulose nanofibers and their application as paper additives. Ind Crop Prod 97:374–387

Balea A, Merayo N, Seara M, Fuente E, Blanco A, Negro C (2016e) Effect of NFC from organosolv corn stalk pulp on retention and drainage during papermaking. Cell Chem Technol 50:377–383

Batchelor W, Sudarno A, Gujjari C, Banham P (2009) Fundamental studies of linting in offset printing of newsprint. In: Advances in pulp and paper research, Oxford 2009, vol 1–3. Pulp & Paper Fundamental Research Society, Bury

Brouillette F, Morneau D, Chabot B, Daneault C (2006) Evaluation of new lint reduction additives in wood-containing paper manufacturing. Pulp Paper Can 107:47–50

Carrasco F, Mutje P, Pelach MA (1996) Refining of bleached cellulosic pulps: characterization by application of the colloidal titration technique. Wood Sci Technol 30:227–236

Delgado-Aguilar M, González I, Pèlach MA, De La Fuente E, Negro C, Mutjé P (2014) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22:789–802

Delgado-Aguilar M, Gonzalez I, Tarres Q, Alcala M, Pelach MA, Mutje P (2015) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResources 10:5345–5355

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Paper Res J 23:299–304

Espinosa E, Tarres Q, Delgado-Aguilar M, Gonzalez I, Mutje P, Rodriguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose 23:837–852. https://doi.org/10.1007/s10570-015-0807-8

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7:5167–5180

González I, Vilaseca F, Alcalá M, Pèlach MA, Boufi S, Mutjé P (2013) Effect of the combination of biobeating and NFC on the physico-mechanical properties of paper. Cellulose 20:1425–1435

Gratton MF, Frigon P (2008) Predicting lint propensity of paper at the mill: a test that works. Appita J 61:284

Haggblom-Ahnger UM, Pakarinen PI, Odell MH, Eklund DE (1998) Conventional and stratified forming of office paper grades. Tappi J 81:149–158

Hansen E (1951) The distribution of filler in paper. Tappi 34:180–185

He M, Cho BU, Won JM (2016) Effect of precipitated calcium carbonate-cellulose nanofibrils composite filler on paper properties. Carbohydr Polym 136:820–825. https://doi.org/10.1016/j.carbpol.2015.09.069

Heintze HU (2006) Offset lint testing: an overview of printing options and issues. Pulp Paper Can 107:30–33

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromol 9:1579–1585. https://doi.org/10.1021/bm800038n

Hoc M (2010) The phenomenon of linting in newsprint printing—literature review. Innventia Report No: 107, NRP47 Sept 2010

Holik H (2006) Handbook of Paper and Board. Wiley, Hoboken

Johansson C et al (2012) Renewable fibers and bio-based materials for packaging applications—a review of recent developments. BioResources 7:1–47

Korhonen MHJ, Laine J (2014) Flocculation and retention of fillers with nanocelluloses. Nord Pulp Paper Res J 29:119–128

Kuutti L, Pajari H, Rovio S, Kokkonen J, Nuopponen M (2016) Chemical recovery in TEMPO oxidation. BioResources 11:6050–6061. https://doi.org/10.15376/biores.11.3.6050-6061

Lestiani R, Batchelor W, Banham P (2013) Investigation of the performance of a lint camera system in identifying lint using image analysis. Appita J 66:299–305

Liu A, Berglund LA (2012) Clay nanopaper composites of nacre-like structure based on montmorrilonite and cellulose nanofibers-improvements due to chitosan addition. Carbohydr Polym 87:53–60. https://doi.org/10.1016/j.carbpol.2011.07.019

Liu AD, Walther A, Ikkala O, Belova L, Berglund LA (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromol 12:633–641. https://doi.org/10.1021/bm101296z

Lourenco AF, Gamelas JAF, Nunes T, Amaral J, Mutje P, Ferreira PJ (2017) Influence of TEMPO-oxidised cellulose nanofibrils on the properties of filler-containing papers. Cellulose 24:349–362. https://doi.org/10.1007/s10570-016-1121-9

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299. https://doi.org/10.1016/j.carbpol.2011.06.030

Marx-Figini M (1978) Significance of the intrinsic viscosity ratio of unsubstituted and nitrated cellulose in different solvents. Die Angew Makromol Chem 72:161–171. https://doi.org/10.1002/apmc.1978.050720114

McDonald JD, Tchepel MV (2010) The effect of dryer section operation on the linting propensity of newsprint. Appita J 63:258

Montgomery J (2010) The role of suction boxes on forming section retention and filler migration. The Univeristy of British Columbia

Odell MH (2000) Paper structure engineering. Appita J 53:371–377

Paakko M et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8:1934–1941. https://doi.org/10.1021/bm061215p

Petroudy SRD, Syverud K, Chinga-Carrasco G, Ghasemain A, Resalati H (2014) Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr Polym 99:311–318. https://doi.org/10.1016/j.carbpol.2013.07.073

Rouger J, Mutje P (1984) Correlation between the cellulose fibers beating and the fixation of a soluble cationic polymer British. Polym J 16:83–86. https://doi.org/10.1002/pi.4980160207

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromol 8:2485–2491. https://doi.org/10.1021/bm0703970

Sehaqui H, Liu AD, Zhou Q, Berglund LA (2010) Fast preparation procedure for large flat cellulose and cellulose/inorganic nanopaper structures. Biomacromol 11:2195–2198. https://doi.org/10.1021/bm100490s

Sehaqui H, Allais M, Zhou Q, Berglund LA (2011) Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Compos Sci Technol 71:382–387. https://doi.org/10.1016/j.compscitech.2010.12.007

Silva DD et al (2010) Impact of micro/nanofibrillated cellulose preparation on the reinforcement properties of paper and composites films. In: Tappi Nano

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494. https://doi.org/10.1007/s10570-010-9405-y

Song HN, Ankerfors M, Hoc M, Lindstrom T (2010) Reduction of the linting and dusting propensity of newspaper using starch and microfibrillated cellulose. Nord Pulp Paper Res J 25:495–504

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111. https://doi.org/10.1007/s10570-011-9533-z

Stelte W, Sanadi AR (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48:11211–11219. https://doi.org/10.1021/ie9011672

Sudarno A, Gujjari C, Rand S, Janko P, Batchelor W, Banham P (2006) Comparison of size distributions of lint particles from different printing operations. Appita J 59:385–390

Sudarno A, Batchelor W, Banham P, Gujjari C (2007) Investigation of the effect of press and paper variables on linting during the offset printing of newsprint. Tappi J 6:25–31

Svedberg A, Lindstrom T (2012) Improvement of the retention-formation relationship using three-component retention aid systems. Nord Pulp Paper Res J 27:86–92

Taipale T, Osterberg M, Nykanen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. https://doi.org/10.1007/s10570-010-9431-9

Tarres Q, Ehman NV, Vallejos ME, Area MC, Delgado-Aguilar M, Mutje P (2017a) Lignocellulosic nanofibers from triticale straw: the influence of hemicelluloses and lignin in their production and properties. Carbohydr Polym 163:20–27. https://doi.org/10.1016/j.carbpol.2017.01.017

Tarres Q, Espinosa E, Dominguez-Robles J, Rodriguez A, Mutje P, Delgado-Aguilar M (2017b) The suitability of banana leaf residue as raw material for the production of high lignin content micro/nano fibers: from residue to value-added products. Ind Crop Prod 99:27–33. https://doi.org/10.1016/j.indcrop.2017.01.021

Wang B, Sain M (2007) Isolation of nanofibers from soybean source and their reinforcing capability on synthetic polymers. Compos Sci Technol 67:2521–2527. https://doi.org/10.1016/j.compscitech.2006.12.015

Wood JR, McDonald JD, Ferry P, Short CB, Cronin DC (1998) The effect of paper machine forming and pressing on offset linting—forming and consolidation in the presses strongly influence sheet linting. Pulp Paper Can 99:53–59

Wood J, Zhang X, Chagaev O, Stationwala M, Goel K, Shallhorn PM, Beaulieu S (2000) The effect of various mechanical and chemical treatment of ray cells on sheet properties and linting. Pulp Paper Can 101:83–87

Acknowledgments

The authors wish to thank the Economy and Competitiveness Ministry of Spain for the support of the project with reference CTQ2013-48090-C2-1-R. The authors also thank to International Paper (Fuenlabrada, Spain) for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balea, A., Merayo, N., Fuente, E. et al. Cellulose nanofibers from residues to improve linting and mechanical properties of recycled paper. Cellulose 25, 1339–1351 (2018). https://doi.org/10.1007/s10570-017-1618-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1618-x