Abstract

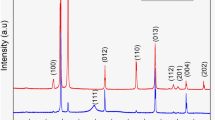

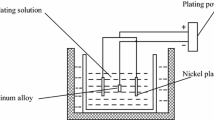

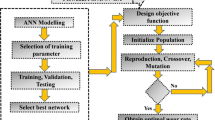

The choice of the electroplating conditions of Ni-based alloys has always been a serious research question. In this study, an artificial neural network based on central composite design modelization were used to determine the desired percentage of Ni and the optimum thickness of the coating before passing to the implementation of the work. Three main factors were found to be very important in this process; namely applied current density (I), pH of the bath and the temperature (T) during electrolysis. The optimum conditions generated by the mathematical model proposed in this work were 42 mA cm−2, pH 4.5 and 50 °C for the Ni-alloys (Zn, Co, Cr and W). Theoretically, the optimum amount of Ni and the thickness of the alloy were 40% and 23 µm, respectively. The SEM images indicated that the optimum (I) would yield homogenous and compact morphologies. Moreover, the XPS investigations revealed that the optimum pH would form a strong Ni bond. Finally, the XRD analysis showed that the optimum T would result in a stable Ni-alloy crystallinity for Zn, Co and Cr. In contrast, Ni-W alloys showed that the amorphous phases were more stable.

Graphic abstract

Similar content being viewed by others

References

Besghaier R, Dhouibi L, Jeannin M, Safi MJ (2019) The synergetic effect of flow velocity and exposing time on the electrochemical behavior of Cu–Ni 90/10 alloy in simulating conditions of desalination plant. Chem Afr 2(3):483–95. https://doi.org/10.1007/s42250-019-00064-z

Nouri K, Saidi M, Walha S, Bessais L, Jemmali M (2020) Magnetocaloric effect in SmNi2 compound. Chem Afr 3(1):111–8. https://doi.org/10.1007/s42250-019-00095-6

Duru CE, Enedoh MC, Duru IA (2019) Physicochemical assessment of borehole water in a reclaimed section of nekede Mechanic Village, Imo State, Nigeria. Chem Afr 2(4):689–98. https://doi.org/10.1007/s42250-019-00077-8

Devillers S, Bonte J, Delhalle J, Mekhalif Z (2018) Morphology and crystallinity of electrodeposited copper particles on nickel controlled by induction heating. Chem Afr 1(3–4):155–65. https://doi.org/10.1007/s42250-018-0020-x

Boulares A, Dhouibi L, Berçot P, Rezrazi EM (2019) Effect of polyethylene glycol 12000 on morphology and corrosion behavior of TiO(OH)2/MnO2/PEG12000 composite electrodeposited on pure copper. Chem Afr 2(4):645–61. https://doi.org/10.1007/s42250-019-00085-8

Sassi W, Dhouibi L, Berçot P, Rezrazi M, Triki E (2012) Comparative study of protective nickel–tungsten deposit behavior obtained by continuous and pulsed currents from citrate–ammonia media. Surf Coat Technol 206(19–20):4235–41

Sassi W, Dhouibi L, Berçot P, Rezrazi M, Triki E (2012) Effect of pyridine on the electrocrystallization and corrosion behavior of Ni–W alloy coated from citrate–ammonia media. Appl Surf Sci 263:373–81

Sassi W, Dhouibi L, Berçot P, Rezrazi M, Triki E (2014) Study of the electroplating mechanism and physicochemical proprieties of deposited Ni-W-Silicate composite alloy. Electrochimica Acta 117:443–52

Sassi W, Dhouibi L, Hihn J-Y, Berçot P, Rezrazi M, Ammar S (2019) Corrosion protection of Cu electrical cable by W-Ni composite coatings doped with TiO2 nanoparticles: influence of pulse currents. J Mater Eng Perform. https://doi.org/10.1007/s11665-019-04288-5

Sassi W, Boubaker H, Bahar S, Othman M, Ghorbal A, Zrelli R et al (2020) A challenge to succeed the electroplating of nanocomposite Ni–Cr alloy onto porous substrate under ultrasonic waves and from a continuous flow titanium nanofluids. J Alloys Compd 828:154437

Hong H, Wang Q, Dong C (2015) Composition formulas of Cu-Ni industrial alloy specifications. Sci China Mater 58(5):355–62. https://doi.org/10.1007/s40843-015-0049-y

Bajwa RS, Khan Z, Bakolas V, Braun W (2016) Water-lubricated Ni-based composite (Ni–Al2O3, Ni–SiC and Ni–ZrO2) thin film coatings for industrial applications. Acta Metall Sin Engl Lett 29(1):8–16. https://doi.org/10.1007/s40195-015-0354-1

Maslyuk VA, Naumenko VY, Ivchenko VI, Podoprigora MI (2015) Wear- and corrosion-resistant Cr3C2–15 % Ni and Cr3C2–28 % Ni hard alloys: production and industrial testing of valves for oil well pumps from these materials. Powder Metall Met Ceram 54(3–4):227–33. https://doi.org/10.1007/s11106-015-9704-9

Li D, Fu G, Zhu M, Li Q, Yin C (2018) Effect of Ni on the corrosion resistance of bridge steel in a simulated hot and humid coastal-industrial atmosphere. Int J Miner Metall Mater 25(3):325–38. https://doi.org/10.1007/s12613-018-1576-9

Abdelsalam HK (2018) Enhancing the structural and spectroscopic properties of Cr3+ ion-doped Ni/Cd/Zn nanoferrite to be applied to industrial applications. J Supercond Nov Magn 31(12):4063–77. https://doi.org/10.1007/s10948-018-4689-5

Ocampo CLM, Mattos OR, Margarit-Mattos ICP, Fabris JD, Pereira MC, Rechenberg HR et al (2006) Influence of Cu and Ni on the morphology and composition of the rust layer of steels exposed to industrial environment. Hyperfine Interact 167(1–3):739–46. https://doi.org/10.1007/s10751-006-9350-1

Holden TM, Tomé CN, Holt RA (1998) Experimental and theoretical studies of the superposition of intergranular and macroscopic strains in Ni-based industrial alloys. Metall Mater Trans A 29(12):2967–73. https://doi.org/10.1007/s11661-998-0204-0

Zhang T, Liu W, Yin Z, Dong B, Zhao Y, Fan Y et al (2020) Effects of the addition of Cu and Ni on the corrosion behavior of weathering steels in corrosive industrial environments. J Mater Eng Perform. https://doi.org/10.1007/s11665-020-04738-5

Uchiya N, Furuta Y, Nishikawa H, Watanabe T, Haga J, Satoh T et al (2008) Ni electroplating on a resist micro-machined by proton beam writing. Microsyst Technol 14(9–11):1537–40. https://doi.org/10.1007/s00542-007-0549-0

Wang J, Wang Y, Xie T, Deng Q (2019) Facile and fast synthesis of Ni composite coating on Ti mesh by electrodeposition method for high-performance hydrogen production. Mater Lett 245:138–41

Eiler K, Suriñach S, Sort J, Pellicer E (2020) Mesoporous Ni-rich Ni–Pt thin films: Electrodeposition, characterization and performance toward hydrogen evolution reaction in acidic media. Appl Catal B Environ 265:118597

Zhang L, Huang T, Zhang M, Guo X, Yuan Z (2008) Studies on the capability and behavior of adsorption of thallium on nano-Al2O3. J Hazard Mater 157(2–3):352–7

Lukaczynska M, Mernissi Cherigui EA, Ceglia A, Van Den Bergh K, De Strycker J, Terryn H et al (2019) Influence of water content and applied potential on the electrodeposition of Ni coatings from deep eutectic solvents. Electrochimica Acta 319:690–704

Chee S-S, Lee J-H (2014) Fabrication of Cu-Ni mixed phase layer using DC electroplating and suppression of Kirkendall voids in Sn-Ag-Cu solder joints. Electron Mater Lett 10(3):637–44. https://doi.org/10.1007/s13391-013-3161-8

Portela DG, Porto MB, de Almeida Neto AF (2019) Parameters variation on Ni–Co–W coating electroplating to evaluate improvements in morphology and corrosion resistance. J Braz Soc Mech Sci Eng 41(12):574. https://doi.org/10.1007/s40430-019-2081-4

Srimathi SN, Mayanna SM (1983) Electroplating of Fe-Ni alloys: a sulphate-amine bath. J Appl Electrochem 13(5):679–86. https://doi.org/10.1007/BF00617826

Srimathi SN, Mayanna SM (1986) Electroplating of Fe-Ni alloys: effects of sulphamic acid and sulphosalicylic acid. J Appl Electrochem 16(1):69–74. https://doi.org/10.1007/BF01015985

Negem M, Helal N, Roy S, Elfeky H, Kardas G (2020) Electroplating of nanocrystalline Ni–Co alloys using cysteine and their electrochemical behaviour in NaOH solution. J Bio- Tribo-Corros 6(2):49. https://doi.org/10.1007/s40735-020-00346-x

Dikici T, Culha O, Toparli M (2010) Study of the mechanical and structural properties of Zn–Ni–Co ternary alloy electroplating. J Coat Technol Res 7(6):787–92. https://doi.org/10.1007/s11998-010-9250-9

Lin H-T, Venault A, Chang Y (2020) Reducing the pathogenicity of wastewater with killer vapor-induced phase separation membranes. J Membr Sci 614:118543

Arabasadi Z, Khorasani M, Akhlaghi S, Fazilat H, Gedde UW, Hedenqvist MS et al (2013) Prediction and optimization of fireproofing properties of intumescent flame retardant coatings using artificial intelligence techniques. Fire Saf J 61:193–9

Pandiyan V, Shevchik S, Wasmer K, Castagne S, Tjahjowidodo T (2020) Modelling and monitoring of abrasive finishing processes using artificial intelligence techniques: A review. J Manuf Process 57:114–35

Khadom AA, Mahdi MS, Mahood HB (2020) Mathematical regression and artificial neural network for prediction of corrosion inhibition process of steel in acidic media. J Bio- Tribo-Corros 6(3):92. https://doi.org/10.1007/s40735-020-00390-7

Mahmmod AA, Khadom AA, Mahood HB (2020) Experimental modeling of inhibition’s mechanism of cupronickel alloy by DETA and EDA into acid corrosive media. J Bio- Tribo-Corros 6(3):85. https://doi.org/10.1007/s40735-020-00381-8

Monaco L, Sodhi RNS, Palumbo G, Erb U (2020) XPS study on the passivity of coarse-grained polycrystalline and electrodeposited nanocrystalline nickel-iron (NiFe) alloys. Corros Sci 176:108902

Lin K-L, Hsu C-J, Hsu I-M, Chang J-T (1992) Electroplating of Ni-Cr on steel with pulse plating. J Mater Eng Perform 1(3):359–61. https://doi.org/10.1007/BF02652390

Zhu L, Younes O, Ashkenasy N, Shacham-Diamand Y, Gileadi E (2002) STM/AFM studies of the evolution of morphology of electroplated Ni/W alloys. Appl Surf Sci 200(1–4):1–14

Duhin A, Rozenblat-Raz A, Burstein L, Inberg A, Horvitz D, Shacham-Diamand Y et al (2014) Growth study of nanoscale Re–Ni coatings on functionalized SiO2 using electroless plating. Appl Surf Sci 313:159–65

Karoui S, Ben Arfi R, Mougin K, Ghorbal A, Assadi AA, Amrane A (2020) Synthesis of novel biocomposite powder for simultaneous removal of hazardous ciprofloxacin and methylene blue: Central composite design, kinetic and isotherm studies using Brouers-Sotolongo family models. J Hazard Mater 387:121675

Ghrib F, Saied T, Bellakhal N (2019) Experimental design methodology applied to the degradation of a cytostatic agent the imatinib mesylate using fenton process. Chem Afr 2(1):103–11. https://doi.org/10.1007/s42250-018-00033-y

Hadhri N, Hamzaoui AH, Ben Ayed T, Saied T (2019) Optimization of tunisian olive pomace oil esterification using response surface methodology. Chem Afr 2(3):497–506. https://doi.org/10.1007/s42250-019-00069-8

Ismael MH, Mahmmod AA, Farhan SN, Khadom AA, Mahood HB (2019) Statistical investigation as a tool for corrosion data explanations and forecasting of reliable operating regions. Chem Afr 2(4):663–71. https://doi.org/10.1007/s42250-019-00074-x

Altamirano-Garcia L, Vazquez-Arenas J, Pritzker M, Luna-Sánchez R, Cabrera-Sierra R (2015) Effects of saccharin and anions (SO4 2−, Cl−) on the electrodeposition of Co–Ni alloys. J Solid State Electrochem 19(2):423–33. https://doi.org/10.1007/s10008-014-2616-7

Srivastava C, Ghosh SK, Rajak S, Sahu AK, Tewari R, Kain V et al (2017) Effect of pH on anomalous co-deposition and current efficiency during electrodeposition of Ni-Zn-P alloys. Surf Coat Technol 313:8–16

Srivastava M, Balaraju JN, Ravisankar B, Anandan C, William Grips VK (2012) High temperature oxidation and corrosion behaviour of Ni/Ni–Co–Al composite coatings. Appl Surf Sci 263:597–607

Srivastav A, Srivastava VC (2009) Adsorptive desulfurization by activated alumina. J Hazard Mater 170(2–3):1133–40

Hammami O, Dhouibi L, Triki E (2009) Influence of Zn–Ni alloy electrodeposition techniques on the coating corrosion behaviour in chloride solution. Surf Coat Technol 203(19):2863–70

Yousefi E, Irannejad A, Sharafi S (2019) Electrodeposition and characterization of nanocrystalline Fe−Ni−Cr alloy coatings synthesized via pulse current method. Trans Nonferrous Met Soc China 29(12):2591–603

Yoon W, Hanson J, Mcbreen J, Yang X (2006) A study on the newly observed intermediate structures during the thermal decomposition of nickel-based layered cathode materials using time-resolved XRD. Electrochem Commun 8(5):859–62

Vitry V, Kanta A-F, Dille J, Delaunois F (2012) Structural state of electroless nickel–boron deposits (5wt.% B): Characterization by XRD and TEM. Surf Coat Technol 206(16):3444–9

Fedi B, Gigandet MP, Hihn J-Y, Mierzejewski S (2016) Structure determination of electrodeposited zinc-nickel alloys: thermal stability and quantification using XRD and potentiodynamic dissolution. Electrochimica Acta 215:652–66

Sabzi M, Dezfuli SM, Mirsaeedghazi SM (2018) The effect of pulse-reverse electroplating bath temperature on the wear/corrosion response of Ni-Co/tungsten carbide nanocomposite coating during layer deposition. Ceram Int 44(16):19492–504

Jafari M, Enayati MH, Salehi M, Nahvi SM, Han JC, Park CG (2016) High temperature oxidation behavior of micro/nanostructured WC-Co coatings deposited from Ni-coated powders using high velocity oxygen fuel spraying. Surf Coat Technol 302:426–37

Jafari M, Han J-C, Seol J-B, Park C-G (2017) Tribological properties of HVOF-sprayed WC-Co coatings deposited from Ni-plated powders at elevated temperature. Surf Coat Technol 327:48–58

Jafari M, Enayati MH, Salehi M, Nahvi SM, Park CG (2013) Improvement in tribological properties of HVOF sprayed WC–Co coatings using electroless Ni–P coated feedstock powders. Surf Coat Technol 235:310–7

Abedini B, Parvini Ahmadi N, Yazdani S, Magagnin L (2020) Electrodeposition and corrosion behavior of Zn−Ni−Mn alloy coatings deposited from alkaline solution. Trans Nonferrous Met Soc China 30(2):548–58

Oliveira RP, Bertagnolli DC, Ferreira EA, da Silva L, Paula AS (2018) Influence of Fe2+ oxidation and its antioxidant ascorbic acid as additive in Zn-Ni-Fe electrodeposition process on a low carbon steel. Surf Coat Technol 349:874–84

Ghaziof S, Gao W (2014) Electrodeposition of single gamma phased Zn–Ni alloy coatings from additive-free acidic bath. Appl Surf Sci 311:635–42

Abou-Krisha MM, Assaf FH, Toghan AA (2006) Electrodeposition of Zn–Ni alloys from sulfate bath. J Solid State Electrochem 11(2):244–52. https://doi.org/10.1007/s10008-006-0099-x

Fashu S, Gu CD, Wang XL, Tu JP (2014) Influence of electrodeposition conditions on the microstructure and corrosion resistance of Zn–Ni alloy coatings from a deep eutectic solvent. Surf Coat 242:34–41

Xiang T, Zhang M, Li C, Dong C, Yang L, Chan W (2018) CeO 2 modified SiO 2 acted as additive in electrodeposition of Zn-Ni alloy coating with enhanced corrosion resistance. J Alloys Compd 736:62–70

Lokhande AC, Shelke A, Babar PT, Bagi JS, Kim JH (2017) Studies on surface treatment of electrodeposited Ni–Zn alloy coatings using saccharin additive. J Solid State Electrochem 21(9):2725–35. https://doi.org/10.1007/s10008-017-3558-7

Pedroza GAG, de Souza CAC, de Jesus MD, de Andrade Lima LRP, Ribeiro DV (2014) Influence of formic acid on the microstructure and corrosion resistance of Zn–Ni alloy coatings by electrodeposition. Surf Coat Technol 258:232–9

Feng Z, Li D, Sun Q, Wang L, Xing P, An M (2018) Insight into the role and mechanism of 2,2-bipyridine as a novel additive for nano-electrodeposition of Zn-Ni alloy. J Alloys Compd 765:1026–34

Bahadormanesh B, Ghorbani M, Kordkolaei NL (2017) Electrodeposition of nanocrystalline Zn/Ni multilayer coatings from single bath: Influences of deposition current densities and number of layers on characteristics of deposits. Appl Surf Sci 404:101–9

Li B, Li D, Xia W, Zhang W (2018) Synthesis and characterization of a novel Zn-Ni and Zn-Ni/Si3N4 composite coating by pulse electrodeposition. Appl Surf Sci 458:665–77

Bahadormanesh B, Ghorbani M (2017) Electrodeposition of Zn–Ni–P compositionally modulated multilayer coatings: An attempt to deposit Ni–P and Zn–Ni alloys from a single bath. Electrochem Commun 81:93–6

Kamnerdkhag P, Toyatornmanesub P, Rodchanarowan A (2018) Effect of deposition rates on morphology and phases of Zn-Ni electrodeposits under controlled pulsed-current Co-electrodeposition. Mater Today Proc 5(3):9404–8

Fashu S, Gu C, Zhang J, Huang M, Wang X, Tu J (2015) Effect of EDTA and NH4Cl additives on electrodeposition of Zn–Ni films from choline chloride-based ionic liquid. Trans Nonferrous Met Soc China 25(6):2054–64

Wang W, Li Z, Meng A, Li Q (2019) Network-like holey NiCo2O4 nanosheet arrays on Ni foam synthesized by electrodeposition for high-performance supercapacitors. J Solid State Electrochem 23(2):635–44. https://doi.org/10.1007/s10008-018-4149-y

Landa-Castro M, Aldana-González J, de Oca-Yemha MGM, Romero-Romo M, Arce-Estrada EM, Palomar-Pardavé M (2020) Ni–Co alloy electrodeposition from the cathode powder of Ni-MH spent batteries leached with a deep eutectic solvent (reline). J Alloys Compd 830:154650

Jović VD, Jović BM, Pavlović MG, Maksimović V (2006) Morphology and composition of Ni–Co alloy powders electrodeposited from ammoniacal electrolyte. J Solid State Electrochem 10(12):959–66. https://doi.org/10.1007/s10008-005-0047-1

You YH, Gu CD, Wang XL, Tu JP (2012) Electrodeposition of Ni–Co alloys from a deep eutectic solvent. Surf Coat Technol 206(17):3632–8

Anand Raj M, Kumaresana D, Arumainathana S (2018) Effect of Co-deposited αCo(HCP) and βCo(FCC) on magnetic property of Co-Ni soft magnet film prepared by Pulsed Electrodeposition. Mater Today Proc 5(2):8761–7

Shao Y, Guo PY, Sun H, Zhou TC, Ding JT, Xu KX et al (2019) Structure and properties of composite Ni–Co–Mn coatings on metal interconnects by electrodeposition. J Alloys Compd 811:152006

Plieth W, Georgiev GS (2005) The Markov chain model of alloy electrodeposition: application to NiCo and NiMo. J Solid State Electrochem 9(12):859–64. https://doi.org/10.1007/s10008-005-0028-4

Li B, Zhang W, Li D (2020) Synthesis and properties of a novel Ni–Co and Ni–Co/ZrO2 composite coating by DC electrodeposition. J Alloys Compd 821:153258

Zamani M, Amadeh A, Lari Baghal SM (2016) Effect of Co content on electrodeposition mechanism and mechanical properties of electrodeposited Ni–Co alloy. Trans Nonferrous Met Soc China 26(2):484–91

Dheeraj PR, Patra A, Sengupta S, Das S, Das K (2017) Synergistic effect of peak current density and nature of surfactant on microstructure, mechanical and electrochemical properties of pulsed electrodeposited Ni-Co-SiC nanocomposites. J Alloys Compd 729:1093–107

Li W, Hao J, Mu S, Liu W (2020) Electrochemical behavior and electrodeposition of Ni-Co alloy from choline chloride-ethylene glycol deep eutectic solvent. Appl Surf Sci 507:144889

Liu C, Su F, Liang J (2016) Nanocrystalline Co-Ni alloy coating produced with supercritical carbon dioxide assisted electrodeposition with excellent wear and corrosion resistance. Surf Coat Technol 292:37–43

Jović VD, Jović BM, Pavlović MG (2006) Electrodeposition of Ni, Co and Ni–Co alloy powders. Electrochimica Acta 51(25):5468–77

Adelkhani H, Arshadi MR (2009) Properties of Fe–Ni–Cr alloy coatings by using direct and pulse current electrodeposition. J Alloys Compd 476(1–2):234–7

Firouzi-Nerbin H, Nasirpouri F, Moslehifard E (2020) Pulse electrodeposition and corrosion properties of nanocrystalline nickel-chromium alloy coatings on copper substrate. J Alloys Compd 822:153712

Soriano Moranchell FA, Sandoval Pineda JM, Hernández Pérez JN, Silva-Rivera US, Cortes Escobedo CA, de González Huerta R (2020) Electrodes modified with Ni electrodeposition decrease hexavalent chromium generation in an alkaline electrolysis process. Int J Hydrog Energy 45:13683–13692

Bertero E, Hasegawa M, Staubli S, Pellicer E, Herrmann IK, Sort J et al (2018) Electrodeposition of amorphous Fe-Cr-Ni stainless steel alloy with high corrosion resistance, low cytotoxicity and soft magnetic properties. Surf Coat Technol 349:745–51

Dolati AG, Ghorbani M, Afshar A (2003) The electrodeposition of quaternary Fe–Cr–Ni–Mo alloys from the chloride-complexing agents electrolyte. Part I. Processing. Surf Coat Technol 166(2–3):105–10

Wasekar NP, Latha SM, Ramakrishna M, Rao DS, Sundararajan G (2016) Pulsed electrodeposition and mechanical properties of Ni-W/SiC nano-composite coatings. Mater Des 112:140–50

Beltowska-Lehman E, Indyka P, Bigos A, Szczerba MJ, Kot M (2015) Ni–W/ZrO2 nanocomposites obtained by ultrasonic DC electrodeposition. Mater Des 80:1–11

Allahyarzadeh MH, Aliofkhazraei M, Rouhaghdam ARS, Torabinejad V (2016) Electrodeposition of Ni–W–Al2O3 nanocomposite coating with functionally graded microstructure. J Alloys Compd 666:217–26

Arunsunai Kumar K, Paruthimal Kalaignan G, Muralidharan VS (2013) Direct and pulse current electrodeposition of Ni–W–TiO2 nanocomposite coatings. Ceram Int 39(3):2827–34

Li B, Li D, Mei T, Xia W, Zhang W (2019) Fabrication and characterization of boron nitride reinforced Ni–W nanocomposite coating by electrodeposition. J Alloys Compd 777:1234–44

Zhang W, Ji C, Li B (2019) Synthesis and properties of Ni–W/ZrO2 nanocomposite coating fabricated by pulse electrodeposition. Results Phys 13:102242

Beltowska-Lehman E, Bigos A, Indyka P, Chojnacka A, Drewienkiewicz A, Zimowski S et al (2018) Optimisation of the electrodeposition process of Ni-W/ZrO 2 nanocomposites. J Electroanal Chem 813:39–51

Oliveira ALM, Costa JD, de Sousa MB, Alves JJN, Campos ARN, Santana RAC et al (2015) Studies on electrodeposition and characterization of the Ni–W–Fe alloys coatings. J Alloys Compd 619:697–703

He H, Jia S (2010) Direct electrodeposition of Cu-Ni-W alloys for the liners for shaped charges. J Mater Sci Technol 26(5):429–32

Wang J, Xu R, Zhang Y (2012) Study on characteristics of Ni-W-B composites containing CeO2 nano-particles prepared by pulse electrodeposition. J Rare Earths 30(1):43–7

Sangeetha S, Kalaignan GP, Anthuvan JT (2015) Pulse electrodeposition of self-lubricating Ni–W/PTFE nanocomposite coatings on mild steel surface. Appl Surf Sci 359:412–9

Yao Y, Yao S, Zhang L, Wang H (2007) Electrodeposition and mechanical and corrosion resistance properties of Ni–W/SiC nanocomposite coatings. Mater Lett 61(1):67–70

Donten M, Cesiulis H, Stojek Z (2000) Electrodeposition and properties of NiW, FeW and FeNiW amorphous alloys A comparative study. Electrochimica Acta 45(20):3389–96

Wang J, Xu R, Zhang Y (2010) Influence of SiO2 nano-particles on microstructures and properties of Ni-W-P/CeO2-SiO2 composites prepared by pulse electrodeposition. Trans Nonferrous Met Soc China 20(5):839–43

Hasegawa M, Guillonneau G, Maeder X, Mohanty G, Wehrs J, Michler J et al (2017) Electrodeposition of dilute Ni-W alloy with enhanced thermal stability: Accessing nanotwinned to nanocrystalline microstructures. Mater Today Commun 12:63–71

Beltowska-Lehman E, Indyka P, Bigos A, Kot M, Tarkowski L (2012) Electrodeposition of nanocrystalline Ni–W coatings strengthened by ultrafine alumina particles. Surf Coat Technol 211:62–6

Tasić GS, Lačnjevac U, Tasić MM, Kaninski MM, Nikolić VM, Žugić DL et al (2013) Influence of electrodeposition parameters of Ni–W on Ni cathode for alkaline water electrolyser. Int J Hydrog Energy 38(11):4291–7

Zhang M, Zhu C, Yang C, Lv Y (2018) Preparation of amorphous Ni-W coating for the current collector of Na/S battery by electrodeposition. Surf Coat Technol 346:40–7

Das MK, Li R, Qin J, Zhang X, Das K, Thueploy A et al (2017) Effect of electrodeposition conditions on structure and mechanical properties of Ni-W/diamond composite coatings. Surf Coat Technol 309:337–43

Indyka P, Beltowska-Lehman E, Tarkowski L, Bigos A, García-Lecina E (2014) Structure characterization of nanocrystalline Ni–W alloys obtained by electrodeposition. J Alloys Compd 590:75–9

Cesiulis H, Baltutiene A, Donten M, Donten M, Stojek Z (2002) Increase in rate of electrodeposition and in Ni(II) concentration in the bath as a way to control grain size of amorphous/nanocrystalline Ni-W alloys. J Solid State Electrochem 6(4):237–44. https://doi.org/10.1007/s100080100225

Bacal P, Donten M, Stojek Z (2017) Electrodeposition of high-tungsten W-Ni-Cu alloys. Impact of copper on deposition process and coating structure. Electrochimica Acta 241:449–58

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sassi, W., Mrad, M., Behera, D. et al. Prediction and optimization of electroplated Ni-based coating composition and thickness using central composite design and artificial neural network. J Appl Electrochem 51, 1591–1604 (2021). https://doi.org/10.1007/s10800-021-01602-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-021-01602-9