Abstract

The complexes of coenzyme Q10 with β- and γ-cyclodextrin in aqueous solutions were prepared in order to improve the water solubility, thermo- and photo-stability of coenzyme Q10. Complex formation resulted in an increase in water solubility at room temperature and pH 6.5 by a factor at least 102. The solubility of coenzyme Q10 in the presence of cyclodextrins linearly increases with temperature and pH. The UV light (λ = 254) and temperature together have a great effect on coenzyme Q10 stability. After 120 min of exposure at 80 °C and UV light about 72.3% of pure coenzyme Q10 was degraded. Thermo- and photo-stability was strongly improved by complex formation; more than 64% of coenzyme Q10 remained unchanged. The formation of complexes was evaluated using IR spectrometry, X-ray diffractometry and TGA/DSC analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

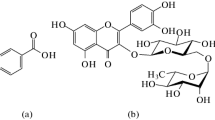

Coenzyme Q10 (CoQ10), also known as ubiquinone or ubidecarenone, is a lipophilic substance involved in a variety of essential cellular processes, such as cellular energy production in the form of adenosine triphosphate, and as a stabilizing agent in cellular membranes [1, 2]. The reduced form of CoQ10 may also act as a radical scavenger that blocks oxidative damage of DNA, lipids, proteins, and other essential molecules [1]. Since CoQ10 improves the cell respiratory chain and stabilizes the mitochondrial membrane, exogenous CoQ10 is used as a nutritional supplement and is highly recommended in treatment of various cardiovascular disorders, degenerative muscle diseases, and during carcinogenesis [3–5].

Chemically it is composed of a benzoquinone ring and 10 isoprenoid units in the side chain. Due to its relatively large molecular weight (863.34 g/mol) as well as its hydrophobic nature, CoQ10 is poorly and slowly absorbed from gastrointestinal tract [6]. It is assumed that the bioavailability of CoQ10 may be improved with an increase of its water solubility, and a number of researchers have attempted to enhance its absorption by creating a more water-miscible formulations. Many different approaches have been used to improve the in vitro dissolution of CoQ10. Some approaches include preparation of nanoparticles into which CoQ10 has been incorporated [7], solubilization in a blend of sorbitan monooleate, polysorbate 80, medium chain triglycerides, propylene glycol, alpha tocopherol and poly vinyl pyrrolidone [8], preparation of redispersible dry emulsion [9], solid dispersion of CoQ10 with Eudragit® [10], fine oil-in-water emulsion by development of self-emulsifying drug delivery system [11] and self-nanoemulsifying drug delivery system [12]. The most recent preparation of CoQ10 is All-Q® 10% CWS/S, which is based on food grade starch [13].

One of the most useful enzyme-modified starch derivatives are cyclodextrins, which are well known as inclusion-complexing agents for small and large molecules [14]. The most common cyclodextrin (CD) is β-CD, a ring molecule consisting of seven glucopyranose units. Having a hydrophilic outer surface and hydrophobic inner cavity gives it a unique ability to form inclusion complexes with lipophilic compounds and increase their water-solubility, stability and/or bioavailability [15–17]. Therefore, Lutka and Pawlaczyk [18] tried to synthesize inclusion complexes of CoQ10 with various CDs. They prepared inclusion complexes of CoQ10 with γ-CD and substituted β-CDs using “kneading” and “heating” methods. While they obtained complexes of CoQ10 with most of the used CDs in solution they could not confirm a complex with non-substituted β-CD nor with α-CD in solid state.

We have already published our work on the in-line synthesis of inclusion complex of CoQ10 with β-CD, where yield of the complexation was only 2–5% [19]. Low yield of that complexation can be explained with the competition of nonpolar interactions of CoQ10 and 1,4-dioxane with the β-CD cavity.

The aim of this work was to investigate the microencapsulation of CoQ10 with β-CD and γ-CD using “co-precipitation” method in aqueous solution, in order to improve CoQ10 water-solubility, and consequently its bioavailability. Improved water-solubility of this complex would enable the preparation of water-based functional food. The solubility studies of CoQ10 with CDs were carried out according to the method described by Higuchi and Connors [20]. In order to improve the existence of the inclusion complex, the raw materials, physical mixtures and the co-precipitated product were characterized and compared using infrared spectroscopy, thermal property analysis and X-ray diffraction. The objective of the present study was also to obtain useful information on thermo- and photo-stability of the complexes of CoQ10 with β-CD and γ-CD under various conditions.

Materials and methods

Materials

Coenzyme Q10 (863 g/mol).–Bulk Medicines & Pharmaceuticals GmbH (Hamburg, Germany).

β-cyclodextrin (1135 g/mol), γ-cyclodextrin (1297 g/mol) and potasium bromide.–Sigma-Aldrich (Steinheim, Germany).

Ethanol, 1,4-dioxane, n-hexane, acetic acid, and hydrochloride acid.–HPLC grade from Merck (Darmstadt, Germany).

Phase solubility studies

Increasing amounts of β-CD or γ-CD solutions (3 mL, 2–14 mM) were added to seven 10 mL vessels containing 32 mg (37 mmol) of CoQ10 and magnetic stirrer. Vessels were closed airtight and the suspensions were vigorously stirred at room temperature for 48 h. The suspensions were filtrated (Milipore Millex-HV PVDF membrane filter 0.45 μm) and the concentration of CoQ10 was determined by HPLC/MS.

The stability constants of complexes, Ks, were calculated from the linear section of the solubility diagrams [20] as:

HPLC/MS determination of CoQ10: Analyses were performed on a Surveyor LC system (Thermo Finnigan, San Jose, CA, USA). HPLC analyses were performed on a Gemini C18 reversed phase column, 150 × 4.6, 5 μ (Phenomenex, Torrance, CA, USA). Mobile phase consisted of ethanol, 1,4-dioxan and acetic acid (92:8:0.1, v/v/v/), respectively. A flow rate of 1.0 mL/min gave adequate resolution, and separation was performed at ambient temperature. The retention time of CoQ10 was 4.3 ± 0.1 min. The injection volume was 10 μL and the LC eluent was directed into the Finnigan LCQ mass spectrometer (Finnigan MAT, San Jose, CA, USA). MS identification and quantification were done in positive APCI ionization mode. Ionization discharge voltage was 6.0 kV, discharge current 5.0 μA, and source temperature 450 °C. Capillary voltage was 3.0 V, tube lens offset was −5.0 V, capillary temperature was 250 °C, sheath gas pressure was 0.2 MPa and auxiliary gas flow was 1.7 L/min. The chromatograms were obtained in SIM mode. Molecular mass (M + H)+ m/z 863.4 ± 1 was used for quantitative determination of CoQ10. Data processing was done with Xcalibur 1.3 software (Thermo Finnigan Corporation, San Jose, CA, USA).

Sample preparation

Physical mixtures: The physical mixtures of CoQ10 with β-CD (fmβ-CDQ10) or γ-CD (fmγ-CDQ10) in 1:1 molar ratio were prepared by gentle dry mixing of exactly weighed amounts of CDs (1.317 and 1.50 g, respectively) with CoQ10 (1.00 g) for 1 h using a mortar and pestle.

Complexes: β-CD (1.500 g, 1.32 mmol) or γ-CD (7.50 g, 5.78 mmol) was dissolved in 15 mL of distilled water at 80 °C. Coenzyme Q10 (1.122 g, 1.30 mmol and 4.983 g, 5.77 mmol, respectively) was added to dissolved CD. Reaction mixture was stirred at 80 °C until the formation of the yellow homogenious paste. The paste was washed with n-hexane at 4 °C to remove CoQ10 adsorbed on the outside surface of the CD. The redundant CD was washed with distilled water at 4 °C. The precipitate was 70% water solution of complex of CoQ10 with β-CD (β-CDQ10) or γ-CD (γ-CDQ10) and it was used for solubility and stability tests, while the lyophylisated precipitate of complex was characterized by infrared spectroscopy, thermal property analysis and X-ray diffraction.

Rate of reaction

The reaction rate of complexes formation was also determined. At times 0, 3, 5, 10, 15 and 30 min 100 μL of suspension was filtrated (Milipore Millex-HV PVDF membrane filter, 0.45 μm). The filtrates were diluted with water 1:100 for β-CDQ10 and 1:400 for γ-CDQ10. 1 and 2 μL of diluted sample were applied on HPTLC plate silica gel 60, 20 × 10 cm (Merck, Darmstadt, Germany) with Camag Automatic Sampler 4 (Camag, Muttenz, Switzerland) for CD determination. Plates were developed with the mobile phase consisting of 1,4-dioxane and water (4:1, v/v). After the development, the plates were dried in a linear stream of hot air for about 5 min in a Programmable TLC dryer P4 (National Institute of Chemistry, Ljubljana, Slovenia). The dried plates were sprayed with 50% solution of H2SO4 in ethanol and heated at 120 °C for 5 min. Quantitative evaluation of black-coloured spots was done in remission mode with Camag TLC videosystem equipped with Videoscan software (Camag, Muttenz, Switzerland).

Solubility studies

Temperature dependence: Into 20 mL of water (pH = 6.5, adjusted with 0.0010 M HCl) 15 mg of fmβ-CDQ10, 25 mg of fmγ-CDQ10, 20 mg of 70% water suspension of β-CDQ10 or 35 mg of 70% water suspension of γ-CDQ10 was weighted. Suspensions were stirred for 120 min, divided to 2 mL per sample, and thermostated for 5 min at 25, 30, 40, 50, 60, 70, 80, 90 and 95 °C. The suspensions were filtrated through membrane filter (Milipore Millex-HV PVDF, 0.45 μm) and the concentration of CoQ10 in the filtrates was determined by HPLC/MS as it was described earlier.

pH dependence: 20 mL of water with different pH (adjusted with 0.010 M HCl) was placed in 50 mL reaction vessel and thermostated to 37 °C, then 15 mg of physical mixture or 20 mg of 70% water suspension of complex was added. The samples were stirred using magnetic stirrer at 37 °C for 30 min. The suspensions were filtrated through membrane filter (Milipore Millex-HV PVDF, 0.45 μm) and the concentration of CoQ10 in the filtrates was determined by HPLC/MS as it was described earlier.

Stability studies

For the photo- and thermo-stability study, 180 mg of CoQ10 was dissolved in 6 mL of n-hexane, 500 mg of 70% water suspension of β-CDQ10 in 5 mL of water and 535 mg of 70% water suspension of γ-CDQ10 in 5 mL of water. 300 μL of sample was dispersed over a quartz-glass plate (25 × 30 mm) and evaporated at room temperature.

Thermo-stability of the samples was determined in the dark at 25 and 80 °C.

Photo-stability of the samples was determined under UV irradiation (254 nm), using a UV lamp, at 25 and 80 °C. The distance between the sample and light source was 15 cm. Samples were withdrawn at fixed time intervals and assayed for CoQ10 and its major photolytic decomposition products using the European Pharmacopoeia 4 [21].

Infrared spectroscopy

Transmittance Fourier transform infrared spectra were recorded on a SPECTRUM 1000 (Perkin-Elmer) FTIR spectrometer with Perkin-Elmer Spectrum software at frequencies from 400 to 4000 cm−1 with a resolution of 2 cm−1, gain = 1, and scans 16. Samples were thoroughly mixed with KBr and compressed into pellet form.

Thermal property analysis

Thermal characteristics of samples were determined with SDT 2960 (TA instruments Inc.) calorimeter and thermogravimetric analyzer. Samples of 3–5 mg were sealed in ceramic pans which were hanging in the heating furnace. In differential scanning calorimetry (DSC), the samples were scanned by one heat/cool cycle between 25 and 400 °C at a heating rate of 10 °C/min. In thermogravimetric analysis (TGA), the weight percentage of remaining material was recorded at the same time as DSC was done. The instrument used nitrogen as the purge gas.

X-ray diffraction

Wide-angle X-ray diffraction patterns of powder samples were obtained at ambient conditions on a Siemens D-5000 X-ray diffractometer with a Cu radiation source (wavelength = 1.54 Å). The supplied voltage and current were set to 40 kV and 30 mA, respectively. Data were collected in the 2θ mode, with 2θ ranging from 2 to 37° in 0.04° steps.

Results and discussion

Ten units long isoprenoid side chain makes CoQ10 a highly lipophilic compound, practically insoluble in water. To increase the water-solubility and improve the bioavailability of CoQ10, its complexes with β-CD and γ-CD in water solution were obtained.

It was believed that β-CD is not a convenient carrier for inclusion complex with CoQ10, for many years [18]. The diameter and volume of the β-CD cavity is about 6.2 Ǻ and 262 Ǻ3, respectively [22]. Di Bernardo and coworkers [23] calculated the length and volume of extended and folded CoQ10. The extended form of CoQ10 is 50 Ǻ long, the volume is 682 Ǻ3 and the expected diameter is 4.0–4.5 Ǻ. CoQ10 molecule with folded tail is 21 Ǻ long, the volume is 351.7 Ǻ3 and the predicted diameter is 4.6–5.0 Ǻ. The volume of the head of CoQ10 is about 60 Ǻ3. Therefore, we believed that the complexation of folded structure of CoQ10 with β-CD would be successful under suitable conditions (water media, elevated temperature).

In order to understand the CoQ10-CD interaction, the physical mixtures and complexes were examined and compared by IR, TGA-DSC and XRD.

Phase solubility studies

In the first part of the present research, a solubility of CoQ10 as a function of β-CD or γ-CD concentration was investigated. The solubility of CoQ10 increases like a function of β-CD concentration and even more considerably with γ-CD concentration. The slopes in the phase-solubility diagrams were linear (R 2 ≥ 0.98) as an AL diagram type according to Higuchi and Connors [20], which was consistent with 1:1 complex formation. The differences in slope showed the relative affinity for the different types of CD. The solubility of pure CoQ10 at pH 6.5 was 9.3·10−8 mol L−1. The increase in CoQ10 solubility after the addition of β-CD or γ-CD to the solution was in the order of 102–103. The apparent stability constants, calculated from the slope of solubility diagrams and intercept were 432.1 and 2207.9 dm3 mol−1 for complexes of CoQ10 with β-CD and γ-CD, respectively.

Rate of reaction

The complexes of CoQ10 with CDs in solutions were obtained using co-precipitation method. CDs solutions at elevated temperature (80 °C) were mixed with CoQ10 in a 1:1 molar ratio. The rate of complex formation was linearly dependent on the blending time (Fig. 1), and therefore zero-order rate reaction in the concentration range from 0.023 M to saturated concentration for β-CD and from 0.122 M to saturated concentration for γ-CD. The reaction rate was calculated from the equation v = (c1 − c0)/(t1 − t0). c1 represents the concentration of the CD at a particular time t1, and c0 represents the initial concentration of the CD at time t0. The calculated reaction rate during the first 30 min was 3.46 · 10−5 mol L−1 s−1 for β-CDQ10 formation, and 1.48 · 10−4 mol L−1 s−1 for γ-CDQ10 formation.

Solubility studies

The results, presented in Table 1, point that the solubility of CoQ10 with β-CD and γ-CD (70% precipitate, obtained in ``Sample preparation’’ section) increases with temperature. The increase of CoQ10 solubility depends on the kind of CD. The solubility of CoQ10 at room temperature is 13.88 and 19.26 mg L−1, and at 95 °C 57.03 and 109.36 mg L−1 in the presence of β-CD and γ-CD, respectively. The solubility of complexes is also pH dependent (Table 2). The glycosidic bond of CDs is hydrolytically cleaved by lowering pH. The ring-opening rate increases with increasing the number of glucosidic units [24]. The results show relatively high solubility of CoQ10 in water at pH 6.5 and 37°C (body temperature) in the form of β-CDQ10 (23.05 mg of CoQ10 per L) or γ-CDQ10 (39.56 mg of CoQ10 per L), and insignificant solubility at pH 2.5 (0.29 mg and <0.0005 mg of CoQ10 per L, respectively). The corresponding physical mixtures show very low water solubility of CoQ10.

Stability studies

CoQ10 is a light-sensitive compound [25] and CDs are well known hosts with ability to improve photo-stability [15, 16]. Therefore, effect of UV irradiation and temperature on CoQ10 degradation was investigated as described in ``Stability studies’’ section.

Figure 2 shows the effect of temperature on CoQ10 stability in the dark. After 92 h of heating at 80 °C the degradation of CoQ10 protected with CD was relatively small (<1%), while the degradation of pure CoQ10 was 3.7%.

The degradation profiles of the CoQ10 and its complexes with β-CD or γ-CD exposed to UV light (254 nm) at room and elevated temperature are given in Fig. 3. β-CD and γ-CD after 120 min at room temperature almost entirely protect CoQ10, while 27.7% of the pure CoQ10 was decomposed. However, at 80 °C about 72.3% of pure CoQ10 was degraded, while β-CD and γ-CD complexation of CoQ10 offer relatively high protection (79.2 and 64.9% of CoQ10 remain, respectively). Neither temperature nor UV irradiation has a great effect on CoQ10 stability, but the combination of both shows a synergistic effect on pure CoQ10 stability. The complex of CoQ10 with γ-CD shows significantly improved stability compared to pure CoQ10 itself, but the best protection of CoQ10 towards the combination of UV light and high temperature seems to be β-CD.

Infrared spectroscopy

The IR spectroscopic analysis confirmed interaction and complex formation between CoQ10 and CD. IR spectra of the complexes were compared with the physical mixtures and pure substances. Changes in the characteristic bands of pure substances confirm the existence of the complex as a new compound with different spectroscopic bands. The spectra of the fmβ-CDQ10 and fmγ-CDQ10, given in Fig. 4, have features of each of the components, CoQ10 and CD. This observation indicated that no intermolecular interaction occurred in the physical mixtures. The comparison of IR spectra of the physical mixtures and complexes shows changes in the C–H stretching complex region (2800–3000 cm−1). In spectra of complexes, two peaks in the 2900–2950 cm−1 region merged into one peak with higher intensity. The position of the characteristic bands at 1648 and 1610 cm−1 corresponding to the benzoquinone ring does not change after the transition from a mixture to the complex, but the intensity of the bands decreases. The spectra of complexes show that bands in the 1450–1260 cm−1 region move or increase relative to the bands in the IR spectra of physical mixtures. The form of the bands in the 1080–1000 cm−1 region of complexes becomes narrower with higher intensity.

Thermal property analysis

The DSC curves of the raw materials and physical mixtures compared with those obtained by co-precipitation method confirmed not only an interaction between the CoQ10 and CD, but also indicated real inclusion. Fig. 5 shows the DSC thermograms for the CoQ10, β-CD, γ-CD, physical mixtures fmβ-CDQ10 and fmγ-CDQ10, and the complexes β-CDQ10 and γ-CDQ10 up to 400°C. The endothermic event on DSC thermogram of CoQ10 at 50°C is associated with a change from solid to liquid aggregate state and the broad thermal peak at around 91°C on thermograms of β-CD and γ-CD can be interpreted as a release of the inclusion water from CDs. The DSC curves of physical mixtures represent a sum of DSC thermograms of CoQ10 and β-CD or γ-CD, suggesting that no interactions can occur during gentle mixing of guest and host molecules. On the other hand, on the thermograms of complexes, the peak corresponding to the melting point of CoQ10 is absent and the endotherms in the range 300–400°C are slightly shifted and of different intensity. Inclusion of CoQ10 in a CD cavity displaced the water originally included in the cavity. The absence of dehydration endotherms in DSC curves of complexes may be an additional indication of inclusion of CoQ10 in the CD cavity.

The TGA thermogram of CoQ10 shows a single, continuous process of thermal decomposition that starts at around 250°C, without the formation of any solid residue. In the case of CDs, the transition in the 65–100°C region reflects the weight loss of water contained in CDs cavity and the thermal decomposition of CDs begins at around 300°C. Figure 6 distinctly shows that TGA thermograms of the physical mixtures and complexes differ considerably in their thermal stability. In the TGA thermograms of physical mixtures the isolation of water contained in the CD cavity can be observed up to 100 °C and the second loss in weight of the physical mixture samples begin in the 250 °C region, as in the case of CoQ10. The complexes studied are stable practically up to 300 °C, demonstrating that thermal stability of the complexes is stronger than that of CoQ10 and CDs. These rather high temperature stable complexes might also provide a great potential benefit in several areas, such as using complexes in food industry, where the sterilization is needed at temperatures above 140 °C.

X-ray diffraction

The X-ray diffraction patterns of solid samples are summarized in Fig. 7. It was established that the pure CoQ10, β-CD and γ-CD have crystalline structures. Physical mixtures diffractograms are the superimposition of the patterns of raw materials, and no crystallinity was lost when the pure CoQ10 and CD were gentle mixed. On the other hand, the co-precipitate products have entirely different patterns in which it is no longer possible to distinguish the characteristic peaks of CoQ10 and CDs, thus confirming the formation of a new compound. The complexes show amorphous behaviour as evidenced by broader peaks of lower intensity which point to the formation of CoQ10 complex with β-CD or γ-CD. However, diffractograms of complexes present peaks at different positions with different relative diffraction peak intensities from those from CoQ10, β-CD or γ-CD, which indicate the formation of another crystalline structure.

Conclusion

The complexes between CoQ10 and CDs were obtained in water-solutions at elevated temperature by the “co-precipitation” method. The complex formation leads to an increase in the water solubility, thermo- and photo-stability. The complex of CoQ10 with β-CD seems to be suitable as a pharmaceutical ingredient and food additive [26]. It is already successfully used as a pharmaceutical ingredient in soft-capsules and syrup, and as a food additive in milk, yogurt, kefir, jam, marmalade and honey.

Abbreviations

- CoQ10:

-

Coenzyme Q10

- CD:

-

Cyclodextrin

- fm-CDQ10:

-

Physical mixtures of CoQ10 with CD

- CDQ10:

-

Complex of CoQ10 with CD

References

Bliznakov, E.G., Wilkins, D.J.: Biochemical and clinical consequences of inhibiting coenzyme Q10 biosynthesis by lipid-lowering HMG-CoA reductase inhibitors (statins): a critical overview. Adv. Ther. 5, 218–228 (1998)

Crane, F.L., Hatefi, Y., Lester, R.L., Widmer, C.: Isolation of a quinone from beef heart mitochondria. Biochim. Biophys. Acta 25, 220–221 (1957). doi:10.1016/0006-3002(57)90457-2

Eggens, I., Elmberger, P.G., Löw, P.: Polyisoprenoid, cholesterol and ubiquinone levels in human hepatocellular carcinomas. Br. J. Exp. Pathol. 70, 83–92 (1989)

Kalen, A., Appelkvist, E.L., Dallner, G.: Age-related changes in the lipid composition of rat and human tissues. Lipids 24, 579–584 (1989). doi:10.1007/BF02535072

Littarru, G.P., Battino, M., Folkers, K.: Clinical aspects of coenzyme Q: improvement of cellular bioenergetics or antioxidant protection? In: Cadenas, E., Packer, L. (eds.) Handbook of antioxidants, pp. 203–239. Marcel Decker, New York (1996)

Greenberg, S., Frishman, W.H.: Coenzyme Q10: a new drug for cardiovascular disease. J. Clin. Pharmacol. 30, 590–608 (1990)

Hsu, C.H., Cui, Z., Mumper, R.J., Jay, M.: Preparation and characterization of novel coenzyme Q10 nanoparticles engineered from microemulsion precursors. AAPS PharmSciTech 4, 32 (2003). doi:10.1208/pt040332

Chopra, R.K., Goldman, R., Sinatra, S.T., Bhagavan, H.N.: Relative bioavailability of coenzyme Q10 formulations in human subjects. Int. J. Vitam. Nutr. Res. 68, 109–113 (1998)

Takeuchi, H., Sasaki, H., Niwa, T., Hino, T., Kawashima, Y., Uesugi, K., Ozawa, H.: Improvement of photostability of ubidecarenone in the formulation of a novel powdered dosage form termed redispersible dry emulsion. Int. J. Pharm. 86, 25–33 (1992). doi:10.1016/0378-5173(92)90027-Y

Nazzal, S., Guven, N., Reddy, I.K., Khan, M.A.: Preparation and characterization of coenzyme Q10-Eudragit® solid dispersion. Drug Dev. Ind. Pharm. 28, 49–57 (2002). doi:10.1081/DDC-120001485

Kommuru, T.R., Gurley, B., Khan, M.A., Reddy, I.K.: Self-emulsifying drug delivery systems (SEDDS) of coenzyme Q10: formulation development and bioavailability assessment. Int. J. Pharm 212, 233–246 (2001). doi:10.1016/S0378-5173(00)00614-1

Nazzal, S., Smalyukh, I.I., Lavrentovich, O.D., Khan, M.A.: Preparation and in vitro characterization of a eutectic based semisolid self-nanoemulsified drug delivery sysstem (SNEDDS) of ubiquinone: mechanism and progress of emulsion formation. Int. J. Pharm. 235, 247–265 (2002). doi:10.1016/S0378-5173(02)00003-0

Ullmann, U., Metzner, J., Schulz, C., Perkins, J., Leuenberger, B.: A new coenzyme Q10 tablet-grade formulation (all-Q®) is bioequivalent to Q-Gel® and both have better bioavailability properties than Q-SorB®. J. Med. Food 8(3), 397–399 (2005). doi:10.1089/jmf.2005.8.397

Szejtli, J.: Inclusion of guest molecules, selectivity and molecular recognition by cyclodextrins. In: Szejtli, J., Osa, T. (eds.) Comprehensive Supramolecular Chemistry, vol. 3, pp. 189–203. Pergamon, Oxford (1996)

Szejtli, J.: Cyclodextrins in diagnostics. Kontakte 1, 31–36 (1988). Darmstad

Van Doorne, H.: Interactions between cyclodextrins and opthalmic drugs. Eur. J. Pharm. Biopharm. 39, 133–139 (1993)

Prosek, M., Butinar, J., Lukanc, B., Milivojevic Fir, M., Milivojevic, L., Krizman, M., Smidovnik, A.: Bioavailability of water-soluble CoQ10 in beagle dogs. J. Pharm. Biomed. Anal. 47, 918–922 (2008). doi:10.1016/j.jpba.2008.04.007

Lutka, A., Pawlaczyk, J.: Inclusion complexation of coenzyme Q10 with cyclodextrins. Acta Poloniae Pharm. Drug Res. 52, 379–386 (1995)

Prosek, M., Smidovnik, A., Fir, M., Strazisar, M.: TLC identification and quantification of coenzyme Q10-β-cyclodextrin complex. JPC 17, 181–185 (2004)

Higuchi, T., Connors, K.A.: Phase solubility techniques. Adv. Anal. Instr. 4, 117–212 (1965)

European Pharmacopoeia 4, pp. 2099–2100. Council of Europe, Strasbourg (2001)

Szjetli, J.: Introduction and general overview of cyclodextrin chemistry. Chem. Rev 98, 1743–1753 (1998). doi:10.1021/cr970022c

Di Bernardo, S., Fato, R., Cassadio, R., Fariselli, P., Lenaz, G.: A high diffusion coefficient for coenzyme Q10 might be related to a folded structure. FEBS Lett 426, 77–80 (1998). doi:10.1016/S0014-5793(98)00313-5

Uekama, K., Irie, T.: Pharmaceutical use of cyclodextrins in various drug formulations. In: Szejtli, J., Osa, T. (eds.) Comprehensive Supramolecular Chemistry, vol. 3. Pergamon, Oxford (1996)

Matsuda, Y., Masahara, R.: Photostability of solid-state ubidecarenone at ordinary and elevated temperatures under exaggerated UV irradiation. J. Pharm. Sci 72, 1198–1203 (1983). doi:10.1002/jps.2600721023

M. Prosek, A. Smidovnik, M. Fir, M. Strazisar, Andrensek M., A. Golc Wondra, J. Zmitek: New water-soluble form of coenzyme Q10 in the form of an inclusion complex with β-cyclodextrin, process of preparing, and use thereof. SI Patent (WO 2005/111224 A2, 24 Nov. 2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fir, M.M., Smidovnik, A., Milivojevic, L. et al. Studies of CoQ10 and cyclodextrin complexes: solubility, thermo- and photo-stability. J Incl Phenom Macrocycl Chem 64, 225–232 (2009). https://doi.org/10.1007/s10847-009-9555-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-009-9555-4