Abstract

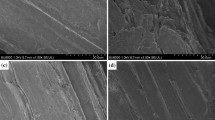

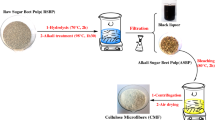

In this study, poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/bamboo pulp fiber (BPF) composites were prepared by melt compounding and injection molding. The crystallization ability, tensile strength and modulus, flexural strength and modulus, and impact strength were found substantially increased by the addition of BPF. Tensile and flexural elongations were also moderately increased at low fiber contents (<20%). BPF demonstrated not only higher strength and modulus, but also higher failure strain than the PHBV8 matrix. Boron nitride (BN) was also investigated as a nucleation agent for PHBV8 and maleic anhydride grafted PHBV8 (MA-PHBV8) as a compatibilizer for the composite system. BN was found to increase the overall properties of the neat polymer and the composites due to refined crystalline structures. MA-PHBV8 improved polymer/fiber interactions and therefore resulted in increased strength and modulus. However, the toughness of the composites was substantially reduced due to the hindrance to fiber pullout, a major energy dissipation source during the composite deformation.

Similar content being viewed by others

References

Herrmann A, Nickel J, Riedel U (1998) Polym Degrad Stab 59:251–261

Riedel U, Nickel J (1999) Angew Makromol Chem 272:34–40

Mohanty AK, Misra M, Drzal LT (2002) J Polym Environ 10:19–26

Saxena M, Gowri S (2003) Polym Compos 24:428–436

Das M, Pal A, Chakraborty D (2006) J Appl Polym Sci 100:238–244

Kori Y, Kitagawa K, Hamada H (2005) J Appl Polym Sci 98:603–612

Mi Y, Chen X, Guo Q (1997) J Appl Polym Sci 64:1267–1273

Chen X, Guo Q, Mi Y (1998) J Appl Polym Sci 69:1891–1899

Lee SH, Wang SQ (2006) Compos Part A 37:80–91

Marchessault RH, Coulombe S (1981) Can J Chem 59:38

Barham PJ, Keller A, Otun EL, Holmes PA (1984) J Mater Sci 19:2781–2794

Holmes PA (1988) In: Development in crystalline polymers. Elsevier Applied Science Publishers, London

Ouajai S, Hodzic A, Shanks RA (2004) J Appl Polym Sci 94:2456–2465

Wong S, Shanks R, Hodzic A (2002) Macromol Mater Eng 287:647–655

Bhardwaj R, Mohanty A, Drzal LT, Pourboghrat F, Misra M (2006) Biomacromolecules 287:647–655

Mohanty AK, Khan MA, Hinrichsen G (2000) Compos Sci Technol 60:1115–1124

Reinsch V, Kelley S (1997) J Appl Polym Sci 64:1785–1796

Fernandes EG, Pietrini M, Chiellini E (2004) Biomacromolecules 5:1200–1205

Singh S, Mohanty AK (2007) Compos Sci technol 67:1753–1763

Van De Velde K, Kiekens P (2002) Polym Test 21:433–442

Luo S, Netravalli AN (1999) J Mater Sci 34:3709–3719

Harper D, Wolcott MP (2004) Compos Part A 35:385–394

Dean D, Marchione AA, Rebenfeld L, Register R (1999) Polym Adv Technol 10:655–668

Carlson D, Nie L, Narayan R, Dubois P (1999) J Appl Polym Sci 72:477–485

John J, Tang J, Bhattacharya M (1998) J Appl Polym Sci 67:1947–1955

Chen C, Peng S, Fei B, Zhuang Y, Dong L, Feng Z, Chen S, Xia H (2003) J Appl Polym Sci 88:659–668

Qian J, Zhu L, Zhang J, Whitehouse RS (2007) J Polym Sci Part B Polym Phys 45:1564–1577

Chen C, Fei B, Peng S, Zhuang Y, Dong L, Feng Z (2002) Eur Polym J 38:1663–1670

Zhang XF, Xie F, Pen ZL, Zhang Y, Zhang YX, Zhou W (2002) Eur Polym J 38:1–6

Zhang JL, Wu L, Zhao ML, Li JC, Wang CL (2005) J Appl Polym Sci 96:883–893

Yuksekkalayci C, Yilmazer U, Orbey N (2004) Polym Eng Sci 39:1216–1222

Bismarck A, Mishra S, Lampke T (2005) Plant fibers as reinforcement for green composites. In: Mohanty A, Misra M, Drzal L (eds) Natural fibers, biopolymers, and biocomposites. Taylor & Francis Group, Boca Raton, pp 37–108

Hull D, Clyne TW (1996) An introduction to composite materials, 2nd edn. Cambridge University Press, Cambridge, p 111, p 112

Agarwal BD, Broutman LJ (1990) Analysis and performance of fiber composites, 2nd edn. Wiley, New York, p 123, p 325

Wibowo AC, Mohanty AK, Misra M, Drzal LT (2004) Ind Eng Chem Res 43:4883–4888

Oksman K, Clemons C (1998) J Appl Polym Sci 67:1503–1513

Tobias BC (1993) Proceedings of the international conference on advanced composite materials. Minerals, Metals & Materials Society, p 623

Nielsen EL (1976) In: Mechanical properties of polymer and composites. Marcel Dekker, New York, p 483

Sheldon RP (1982) Composite polymeric materials. Applied Science Publisher, London, pp 86–88

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, L., Huang, J., Qian, J. et al. Study of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Bamboo Pulp Fiber Composites: Effects of Nucleation Agent and Compatibilizer. J Polym Environ 16, 83–93 (2008). https://doi.org/10.1007/s10924-008-0086-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-008-0086-7