Abstract

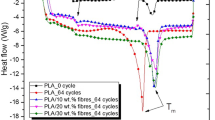

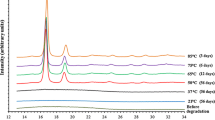

30 wt% aligned untreated long hemp fibre/polylactic acid (AUL) and aligned alkali treated long hemp fibre/polylactic acid (AAL) composites were produced by film stacking and subjected to hygrothermal ageing environment along with neat polylactic acid (PLA). Hygrothermal ageing was carried out by immersing samples in distilled water at 25 and 50 °C over a period of 3 months. It was found that both neat PLA and composites followed Fickian diffusion. Higher temperature generally increased the Diffusion coefficient, D of neat PLA and composites, as well as shortening the saturation time. Neat PLA had the lowest D value followed by AAL composites and then AUL composites. After hygrothermal ageing, tensile and flexural strength, Young’s and flexural modulus and K Ic were found to decrease and impact strength was found to increase for both AUL and AAL composites. AUL composites had greater overall reduction in mechanical properties than that for AAL composites after hygrothermal ageing. Crystallinity contents of the hygrothermal aged composites support the results of the deterioration of mechanical properties upon exposure to hygrothermal ageing environment.

Similar content being viewed by others

References

Peijs T, Melick HGH, Garkhail SK, Pott GT, Baille CA (1998) Proceedings of the European conference on composite materials: science, technologies and applications, ECCM-8, pp 119–126

Rowell RM (1995) Proceedings of a seminar, Copenhagen, Denmark, pp 27–41

Gassan J, Bledzki AK (1997) Polym Compos 18:179–184

Clemons C (2002) J For Prod 52:10–18

Morton J, Quarmley J, Rossi L (2003) Proceedings of 7th international conference on woodfiber-plastic composites, Forest Products Society (FPS), p 376

Rowell RM (1991) Wood and cellulose chemistry. Marcel Dekker, New York

Andreopoulos AG, Tarantili PA (1988) J Appl Polym Sci 70:747–755

Springer GS, Technomic (1981/1984/1988)1-3

Lin Q, Zhou X, Dai G (2002) J Appl Polym Sci 85:2824–2832

Comyn J (1985) Polymer permeability. Elsevier Applied Science Publishers, London

Crank JJ, Park GS (1968) Organic vapours above the glass transition temperature. Academic Press, London

Crank J (1956) The mathematics of diffusion, p 347

Islam MS, Pickering KL, Foreman NJ (2009) J Appl Polym Sci. doi:10.1002/app.31335

Wunderlich B (1958) J Chem Phys 29:1395–1404

Ljungberg N, Wesslen B (2005) Biomacromolecules 6:1789–1796

Reinsch VE, Kelley SS (1997) J Appl Polym Sci 64:1785

Vasanthakumari R, Pennings A (1983) Polymer 24:175

Nam JY, Ray SS, Okamoto M (2003) Macromolecules 36:7126

Islam MS, Pickering KL, Foreman NJ (2009) J Adhes Sci Technol 23:2085–2107

Felix JM, Gatenholm PJ (1991) J Appl Polym Sci 42:609

Bledzki AK, Reihmane S, Gassan J (1996) J Appl Polym Sci 59:1329–1336

Joseph PV, Rabello MS, Mattoso LHC, Joseph K, Thomas S (2002) Compos Sci Technol 62:1357–1372

Zhou J, Lucas JP (1995) Compos Sci Technol 53:57–64

Chow CPL, Xing XS, Li RKY (2007) Compos Sci Technol 67:306–313

Proikakis CS, Mamouzelos NJ, Tarantili PA, Andreopoulos AG (2006) Polym Degrad Stabil 91:614–619

Zhang X, Espiritu M, Bilyk A, Kurniawan L (2008) Polym Degrad Stabil 93:1964–1970

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Islam, M.S., Pickering, K.L. & Foreman, N.J. Influence of Hygrothermal Ageing on the Physico-Mechanical Properties of Alkali Treated Industrial Hemp Fibre Reinforced Polylactic Acid Composites. J Polym Environ 18, 696–704 (2010). https://doi.org/10.1007/s10924-010-0225-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-010-0225-9