Abstract

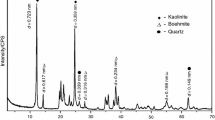

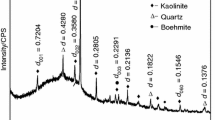

The thermal behavior of two mineral-type coal gangues under different temperature conditions was investigated by heating treatment of kaolinite-type coal gangue and illite-type coal gangue based on thermal analysis, X-ray diffraction (XRD), infrared spectroscopy (IR) and scanning electron microscopy (SEM). Thermogravimetric, differential thermogravimetric and differential scanning calorimetry results show the thermal decomposition process of kaolinite-type coal gangue and illite-type coal gangue can be divided into three stages, thermal decomposition of kaolinite and illite clay minerals occurred in the first stage and the third stage, and thermal decomposition of carbon material in coal gangue samples occurred in the second stage. Compared with illite-type coal gangue, the volatile of kaolinite-type coal gangue is released more intensely and pyrolysis performance of kaolinite-type coal gangue was better; initial temperature of heat decomposition was lower. The XRD, IR and SEM results showed the mineral phase transformation of kaolinite-type coal gangue occurred at 500 °C, the microscopic kaolinite changed obviously and its flake and layered structure started to break, and the phase of kaolinite transformed into amorphous glassy state, which was metakaolinite. In contrast, the mineral phase transformation of illite-type coal gangue occurred at 900 °C. According to the results of various research methods, it is considered that the thermal stability of kaolinite-type coal gangue is lower than that of illite-type coal gangue. This study has some theoretical significance for the rational use of coal gangue to produce highly activity powder materials.

Similar content being viewed by others

References

Bian Z, Miao X, Lei S, Chen S-E, Wang W, Struthers S. The challenges of reusing mining and mineral-processing wastes. Science. 2012;337(6095):702–3.

Tian HZ, Lu L, Hao JM, Gao JJ, Cheng K, Liu KY, et al. A review of key hazardous trace elements in chinese coals: abundance, occurrence, behavior during coal combustion and their environmental impacts. Energy Fuels. 2013;27(2):601–14.

Li C, Wan J, Sun H, Li L. Investigation on the activation of coal gangue by a new compound method. J Hazard Mater. 2010;179(1–3):515–20.

Cheng H, Liu Q, Yang J, Ma S, Frost RL. The thermal behavior of kaolinite intercalation complexes-a review. Thermochim Acta. 2012;545:1–13.

Ji H, Fang M, Huang Z, Chen K, Li W, Liu Y-G. Phase transformation of coal gangue by aluminothermic reduction nitridation: influence of sintering temperature and aluminum content. Appl Clay Sci. 2014;101:94–9.

Li L, Zhang Y, Zhang Y, Sun J, Hao Z. The thermal activation process of coal gangue selected from zhungeer in China. J Therm Anal Calorim. 2016;126(3):1559–66.

Wu J, Wang B, Cheng F. Thermal and kinetic characteristics of combustion of coal sludge. J Therm Anal Calorim. 2017;129(3):1899–1909.

Zhang Y, Nakano J, Liu L, Wang X, Zhang Z. Co-combustion and emission characteristics of coal gangue and low-quality coal. J Therm Anal Calorim. 2015;120(3):1883–92.

Ion RM, Radovici C, Fierascu RC, Fierascu I. Thermal and mineralogical investigations of iron archaeological materials. J Therm Anal Calorim. 2015;121(3):1247–53.

Cheng H, Yang J, Liu Q, He J, Frost RL. Thermogravimetric analysis-mass spectrometry (tg-ms) of selected chinese kaolinites. Thermochim Acta. 2010;507–508:106–14.

Cheng H, Yang J, Frost RL, Wu Z. Infrared transmission and emission spectroscopic study of selected chinese palygorskites. Spectrochimica Acta—Part A: Molecular and Biomolecular Spectroscopy. 2011;83(1):518–24.

Cheng H, Liu Q, Cui X, Zhang Q, Zhang Z, Frost RL. Mechanism of dehydroxylation temperature decrease and high temperature phase transition of coal-bearing strata kaolinite intercalated by potassium acetate. J Colloid Interface Sci. 2012;376(1):47–56.

Cheng H, Liu Q, Yang J, Zhang Q, Frost RL. Thermal behavior and decomposition of kaolinite-potassium acetate intercalation composite. Thermochim Acta. 2010;503–504:16–20.

Cheng H, Hou X, Liu Q, Li X, Frost RL. New insights into the molecular structure of kaolinite–methanol intercalation complexes. Appl Clay Sci. 2015;109–110:55–63.

Húlan T, Trník A, Kaljuvee T, Uibu M, Štubňa I, Kallavus U, et al. The study of firing of a ceramic body made from illite and fluidized bed combustion fly ash. J Therm Anal Calorim. 2017;127(1):79–89.

Cheng H, Li K, Liu Q, Zhang S, Li X, Frost RL. Insight into the thermal decomposition of kaolinite intercalated with potassium acetate: an evolved gas analysis. J Therm Anal Calorim. 2014;117(3):1231–9.

Cheng H, Liu Q, Liu J, Sun B, Kang Y, Frost RL. Tg-ms-ftir (evolved gas analysis) of kaolinite-urea intercalation complex. J Therm Anal Calorim. 2014;116(1):195–203.

Yuan P, Tan D, Annabi-Bergaya F. Properties and applications of halloysite nanotubes: recent research advances and future prospects. Appl Clay Sci. 2015;112–113:75–93.

Yuan P, Tan D, Annabi-Bergaya F, Yan W, Liu D, Liu Z. From platy kaolinite to aluminosilicate nanoroll via one-step delamination of kaolinite: effect of the temperature of intercalation. Appl Clay Sci. 2013;83–84:68–76.

Húlan T, Trník A, Medveď I. Kinetics of thermal expansion of illite-based ceramics in the dehydroxylation region during heating. J Therm Anal Calorim. 2017;127(1):291–8.

Bobos I, Eberl DD. Thickness distributions and evolution of growth mechanisms of nh4-illite from the fossil hydrothermal system of harghita bãi, eastern carpathians, romania. Clays Clay Miner. 2013;61(4):375–91.

Cheng H, Xu P, Wang D, Frost RL. Thermal decomposition behavior and de-intercalation kinetics of kaolinite/quaternary ammonium salt complexes. J Therm Anal Calorim. 2016;126(2):421–33.

Šatava V. Mechanism and kinetics from non-isothermal tg traces. Thermochim Acta. 1971;2(5):423–8.

Elder JP. The `e–ln(a)–f(α)’ triplet in non-isothermal reaction kinetics analysis1,2. Thermochim Acta. 1998;318(1–2):229–38.

Kubliha M, Trnovcová V, Ondruška J, Štubňa I, Bošák O, Kaljuvee T, et al. Dc conductivity of illitic clay after various firing. J Therm Anal Calorim. 2016;124(1):81–6.

Wen X, He H, Zhu J, Jun Y, Ye C, Deng F. Arrangement, conformation, and mobility of surfactant molecules intercalated in montmorillonite prepared at different pillaring reagent concentrations as studied by solid-state nmr spectroscopy. J Colloid Interface Sci. 2006;299(2):754–60.

Acknowledgements

We thank the Key Laboratory of Resource Survey and Research of Hebei Province. We are also grateful to the anonymous reviewers and the journal editors. This work is supported by the Nature Science Foundation of China (No. 41675150) and the Nature Science Foundation of Hebei Province, China (No. D2017402150).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, B., Liu, Q., Ai, B. et al. Thermal decomposition of selected coal gangue. J Therm Anal Calorim 131, 1413–1422 (2018). https://doi.org/10.1007/s10973-017-6687-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6687-4