Abstract

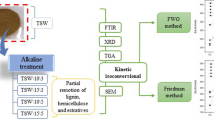

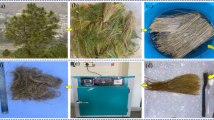

This work aims to evaluate the alkaline treatment using NaOH of the agroindustrial residues of grape stalks (GS) and yerba mate (YM) in order to improve their adhesion in applications in the area of polymer composites. The samples were evaluated according to the chemical analysis, Fourier transform infrared spectroscopy, X-ray diffraction, scanning electron microscopy, thermogravimetric analysis and kinetic study. It was observed that after the alkaline treatment, there was a change in the morphology of the samples due to the partial removal of lignin and hemicellulose, which is consistent with the chemical analysis and FTIR. The activation energy (Ea) found was of 252.79 ± 21.07 kJ mol−1, 218.99 ± 3.28 kJ mol−1, 236.05 ± 9.50 kJ mol−1 and 216.25 ± 14.87 kJ mol−1 for GS, GSNaOH, YM and YMNaOH samples, respectively, confirming the fibers that present a larger amount of lignin require higher activation energy for the degradation. Thus, this material has the potential to be used as a reinforcing filler in composite materials because of the modifications caused by the alkaline treatment, which improves the matrix/fiber interface.

Similar content being viewed by others

References

Dorez G, Ferry L, Sonnier R, Taguet A, Lopez-Cuesta JM. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J Anal Appl Pyrolysis. 2014;107:323–31.

Sepe R, Bollino F, Boccarusso L, Caputo F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos Part B Eng. 2018;133:210–7.

Nuruddin M, Uddin MJ, Jeelani S, Hosur M, Baah D. A novel approach for extracting cellulose nanofibers from lignocellulosic biomass by ball milling combined with chemical treatment. J Appl Polym Sci. 2015;133:1–10.

Romano A, Lindman B, Alves L, Medronho B, Ventura J, Antunes FE, et al. Unusual extraction and characterization of nanocrystalline cellulose from cellulose derivatives. J Mol Liq. 2014;210:106–12.

Hong CK, Hwang I, Park DH, Hwang BS, Kim N, Nah C. Mechanical properties of silanized jute–polypropylene composites. J Ind Eng Chem. 2007;14:71–6.

Collazo-Bigliardi S, Ortega-Toro R, Chiralt Boix A. Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr Polym. 2018;191:205–15.

Naili H, Jelidi A, Limam O, Khiari R. Extraction process optimization of Juncus plant fibers for its use in a green composite. Ind Crops Prod. 2017;107:172–83.

Kalia S, Kaith BS, Kaur I. Novel pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci. 2009;49(7):1253–73.

Li X, Tabil LG, Panigrahi S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ. 2007;15:25–33.

Nabinejad O, Sujan D, Rahman ME, Davies IJ. Effect of filler load on the curing behavior and mechanical and thermal performance of wood flour filled thermoset composites. J Clean Prod. 2017;164:1145–56.

Panaitescu DM, Nicolae CA, Vuluga Z, Vitelaru C, Sanporean CG, Zaharia C, et al. Influence of hemp fibers with modified surface on polypropylene composites. J Ind Eng Chem. 2016;37:137–46.

Sampathkumar D, Punyamurthy R, Bennehalli B, Venkateshappa SC. Physical characterization of natural lignocellulosic single areca fiber. Cienc e Tecnol dos Mater. 2015;27:121–35.

Arrieta MP, Peponi L, López D, Fernández-García M. Recovery of yerba mate (Ilex paraguariensis) residue for the development of PLA-based bionanocomposite films. Ind Crops Prod. 2018;111:317–28.

Ping L, Brosse N, Sannigrahi P, Ragauskas A. Evaluation of grape stalks as a bioresource. Ind Crops Prod. 2011;33:200–4.

Sinclair A, Jiang L, Bajwa D, Bajwa S, Tangpong S, Wang X. Cellulose nanofibers produced from various agricultural residues and their reinforcement effects in polymer nanocomposites. J Appl Polym Sci. 2018;135:9–11.

Frone NA, Panaitescu DM, Chiulan I, et al. Thermal and mechanical behavior of biodegradable polyester films containing cellulose nanofibers. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08218-4.

Gnoatto SCB, Bassani VL, Coelho GC, Schenkel EP. Influência do método de extração nos teores de metilxantinas em erva-mate (Ilex paraguariensis A. St.-Hil., Aquifoliaceae). Quim Nova. 2007;30:304–7.

IBGE. Brazilian Institute of Geography and Statistics. Municipal agricultural production. Rio de Janeiro: IBGE; 2014. Available in, http://www.sidra.ibge.gov.br/bda/tabela/protabl.asp?c¼1613&z¼t&o¼1&i¼P. [Accessed 18 June 2019].

Catto AL, Dahlem MA Jr, Hansen B, et al. Characterization of polypropylene composites using yerba mate fibers as reinforcing filler. Compos Part B Eng. 2019;174:106935.

Dahlem MA Jr, Borsoi C, Hansen B, Catto AL. Evaluation of different methods for extraction of nanocellulose from yerba mate residues. Carbohydr Polym. 2019;218:78–86.

Gonçalves M, Guerreiro MC, Bianchi ML, Carlos L, Oliveira A, Pereira EI, et al. Produção de carvão a partir de resíduo de erva-mate para a remoção de contaminantes orgânicos de meio aquoso. Ciênc agrotec Lavras. 2007;31:1386–91.

Prozil SO, Evtuguin DV, Lopes LPC. Chemical composition of grape stalks of Vitis vinifera L. from red grape pomaces. Ind Crops Prod. 2012;35:178–84.

Pujol D, Liu C, Fiol N, Olivella MÀ, Gominho J, Villaescusa I, et al. Chemical characterization of different granulometric fractions of grape stalks waste. Ind Crops Prod. 2013;50:494–500.

de Oliveira RVB, Dal Castel C, Bertuoli PT, Bianchi O, Hillig E. Avaliação da degradação não-isotérmica de madeira através de termogravimetria-TGA. Polímeros. 2010;20:395–400.

Wu Q, Yao F, Xu X, Mei C, Zhou D. Thermal degradation of rice straw fibers: global kinetic modeling with isothermal thermogravimetric analysis. J Ind Eng Chem. 2013;19:670–6.

Grigiante M, Brighenti M, Antolini D. Analysis of the impact of TG data sets on activation energy (Ea) Case study applied to torrefaction of biomasses by means of isoconversional methods. J Therm Anal Calorim. 2017;129:553–65.

Jia C, Chen J, Liang J, Song S, Liu K, Jiang A, et al. Pyrolysis characteristics and kinetic analysis of rice husk. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08366-7.

Chen D, Lu SE. Analysis of pyrolysis characteristics and kinetics of sweet sorghum bagasse and cotton stalk. J Therm Anal Calorim. 2017;131:1899–909.

Santos RD, Ferreira SR, Oliveira GE, Silva FA, Souza FG, Toledo Filho RD. Influence of alkaline hornification treatment cycles on the mechanical behavior in curaua fibers. Macromol Symp. 2018;381:1–6.

Beltrami LVR, Scienza LC, Zattera AJ. Efeito do tratamento alcalino de fibras de curauá sobre as propriedades de compósitos de matriz biodegradável. Polímeros Ciência e Tecnol. 2014;24:388–94.

Zhu J, Zhu H, Immonen K, Brighton J, Abhyankar H. Improving mechanical properties of novel flax/tannin composites through different chemical treatments. Ind Crops Prod. 2015;67:346–54.

Segal L, Creely JJ, Martin AE Jr., Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using X-ray diffractometer. Text Res J. 1959;29(10):786-94.

Borsoi C, Zimmernnam MVG, Zattera AJ, Santana RMC, Ferreira CA. Thermal degradation behavior of cellulose nanofibers and nanowhiskers. J Therm Anal Calorim. 2016;126:1867–78.

Ornaghi HL, Poletto M, Zattera AJ, Amico SC. Correlation of the thermal stability and the decomposition kinetics of six different vegetal fibers. Cellulose. 2014;21:177–88.

Ounas A, Aboulkas A, El harfi K K, Bacaoui A, Yaacoubi A. Pyrolysis of olive residue and sugar cane bagasse: non-isothermal thermogravimetric kinetic analysis. Bioresour Technol. 2011;102:11234–8.

Poletto M, Pistor V, Zeni M, Zattera AJ. Crystalline properties and decomposition kinetics of cellulose fibers in wood pulp obtained by two pulping processes. Polym Degrad Stab. 2011;96:679–85.

Poletto M, Zattera AJ, Santana RMC. Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol. 2012;126:7–12.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM. Constant rate thermal analysis for thermal stability studies of polymers. Polym Degrad Stab. 2011;96:974–81.

Guo W, Xu Y, Wu Q, Lei Y, Yao F. Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2007;93:90–8.

Zheng C, Li D, Ek M. Mechanism and kinetics of thermal degradation of insulating materials developed from cellulose fiber and fire retardants. J Therm Anal Calorim. 2018;135:3015–27.

Rosa RC da, Giesbrecht BM, Pedrazzi C, Raddatz DD, Corrêa R, Gentil M, et al. Caracterização química da madeira. Congr Bras Ciência e Tecnol da Madeira. 2017.

Prozil SO, Mendes JA, Evtuguin DV, Lopes LPC. Caracterização quimica e estrutural do engaço da uva e avaliação do seu potencial como matéria-prima lenhocelulósica. Millenium. 2013;44:23–40.

Spigno G, Pizzorno T, De Faveri DM. Cellulose and hemicelluloses recovery from grape stalks. Bioresour Technol. 2008;99:4329–37.

Frollini E, Bartolucci N, Sisti L, Celli A. Poly (butylene succinate) reinforced with different lignocellulosic fibers. Ind Crops Prod. 2013;45:160–9.

Spigno G, Maggi L, Amendola D, Dragoni M, De Faveri DM. Influence of cultivar on the lignocellulosic fractionation of grape stalks. Ind Crops Prod. 2013;46:283–9.

Mondragon G, Fernandes S, Retegi A, Peña C, Algar I, Eceiza A, et al. A common strategy to extracting cellulose nanoentities from different plants. Ind Crops Prod. 2014;55:140–8.

Sanjay MR, Madhu P, Jawaid M, Senthamaraikannan P, Senthil S, Pradeep S. Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod. 2018;172:566–81.

Wang W, Liang T, Bai H, Dong W, Liu X. All cellulose composites based on cellulose diacetate and nanofibrillated cellulose prepared by alkali treatment. Carbohydr Polym. 2018;179:297–304.

Lu P, Hsieh YL. Cellulose isolation and core-shell nanostructures of cellulose nanocrystals from chardonnay grape skins. Carbohydr Polym. 2012;87:2546–53.

Cheng G, Zhou M, Wei YJ, Cheng F, Zhu PX. Comparison of mechanical reinforcement effects of cellulose nanocrystal, cellulose nanofiber, and microfibrillated cellulose in starch composites. Polym Compos. 2019;40:E365–72.

Wang Z, Qiao X, Sun K. Rice straw cellulose nanofibrils reinforced poly(vinyl alcohol) composite films. Carbohydr Polym. 2018;197:442–50.

Buson RF, Melo LFL, Oliveira MN, Rangel GAVP, Deus EP. Physical and mechanical characterization of surface treated bamboo fibers. Sci Technol Mater. 2018;30:67–73.

de Carvalho VS, Tannous K. Thermal decomposition kinetics modeling of energy cane Saccharum robustum. Thermochim Acta. 2017;657:56–65.

Navas CS, Reboredo MM, Granados DL. Comparative study of agroindustrial wastes for their use in polymer matrix composites. Procedia Mater Sci. 2015;8:778–85.

Huang Z, Teng QYL. A comparison study on thermal decomposition behavior of poly (L-lactide) with different kinetic models. J Therm Anal Calorim. 2015;119:2015–7.

Ornaghi Júnior HL, Zattera AJ, Amico SC. Thermal behavior and the compensation effect of vegetal fibers. Cellulose. 2014;21:189–201.

Henrique MA, Morais LC de, Gurgel LVA, Flauzino Neto WP, da Barud HS, Martins DF, et al. Kinetic study of the thermal decomposition of cellulose nanocrystals with different polymorphs, cellulose I and II, extracted from different sources and using different types of acids. Ind Crops Prod. 2015;76:128–40.

Acknowledgements

The authors would like to thank CAPES and UNIVATES for the financial support, and company manufacturer Elacy for donating the residues of yerba mate.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Borsoi, C., Dahlem Júnior, M.A., Beltrami, L.V.R. et al. Effects of alkaline treatment and kinetic analysis of agroindustrial residues from grape stalks and yerba mate fibers. J Therm Anal Calorim 139, 3275–3286 (2020). https://doi.org/10.1007/s10973-019-08666-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08666-y