Abstract

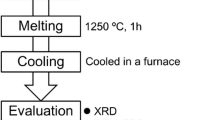

The cold crystallization kinetics of the glass-crystal composition (90.3 vol% of glass) made of slag from the joint smelting of oxidized nickel and sulfide copper ores were studied in the temperature range from 876 to 1003 °C with a heating rate of 5–20 °C·min–1 in an inert atmosphere (the elemental composition of slag is mass%: 0.09 Ni, 0.12 Cu, 0.02 Co, 0.2 Zn, 15.7 Fe, 0.2 S, 50.0 SiO2, 14.2 MgO, 4.8 Al2O3, and 9.4 CaO; particle size < 0.125 mm). XRD data showed that, depending on heating rate, different combinations of crystalline phases could be released in the glass matrix, such as cummingtonite, SiO2 polymorphs, epistilbite, rankinite, wadsleyite, merwinite, and alite. The glass content has been reduced to 54.2 mass% during cold crystallization. The cold crystallization kinetic parameters were estimated by treating the non-isothermal DSC data by Kissinger (classical and advanced), Ozawa, and Augis–Bennett methods. The apparent activation energy, Avrami exponent, and dimensionality of crystal growth are found to be 659 kJ·mol–1, 2.8, and 1.8, respectively. The process is dominated by bulk nucleation with an increase in the number of nuclei under conditions of combined two- and one-dimensional crystal growth. During cold crystallization, 1.3 times more volume of crystals are found to release than when the melted slag is cooled, and there is no need for fine grinding of the raw material. Annealing of granular slag could be a more efficient method of producing glass–ceramics based on the FeOx–CaO–MgO–Al2O3–SiO2 system than the petrurgic method.

Similar content being viewed by others

Availability of data and materials (data transparency)

Not applicable.

Code availability (software application or custom code)

Not applicable.

References

Selivanov EN, Gulyaeva RI, Klyushnikov AM. Study of structure and phase composition of copper-cobalt sulfide ores of Dergamyshskoe deposit. Tsvetnye Metally. 2016;3:13–17. Doi: https://doi.org/10.17580/tsm.2016.03.02.

Selivanov EN, Klyushnikov AM, Gulyaeva RI. Application of sulfide copper ores oxidizing roasting products as sulfidizing agent during melting nickel raw materials to matte. Metallurgist. 2019;63(7–8):867–87. https://doi.org/10.1007/s11015-019-00901-z.

Klyushnikov AM, Gulyaeva RI, Selivanov EN, Pikalov SM. Kinetics and mechanism of oxidation for nickel-containing pyrrhotite tailings. Int J Miner Metall Mater. 2021;28(9):1469–77. https://doi.org/10.1007/s12613-020-2109-x.

Crundwell FK, Moats MS, Ramachandran V, Robinson TG, Dawenport WG. Extractive metallurgy of nickel, cobalt and platinum-group metals. Oxford: Elsevier; 2011.

Warner AEM, Diaz CM, Dalvi AD, Mackey PJ, Tarasov AV, Jones RT. JOM World Nonferrous Smelter Survey Part IV: Nickel: Sulfide. JOM. 2007;59:58–72. https://doi.org/10.1007/s11837-007-0056-x.

Cusano G, Gonzalo MR, Farrell F, Remus R, Roudier S, Delgado Sancho L. Best Available Techniques (BAT) Reference Document for the main Non-Ferrous Metals Industries, EUR 28648 EN, pp 902–910.

Lotosh VE. Pererabotka othodov prirodopol'zovaniya (Recycling of Environmental Wastes). Yekaterinburg: Poligrafist, 2007 (in Russian).

Timonin AS. Inzhenerno-ekologicheskij spravochnik (Engineering and Environmental Reference Guide). Vol. 3. Kaluga: Izdatel'stvo N. Bochkaryovoj, 2003 (in Russian).

Zhang H, Wang H, Zhu X, Qiu Y-J, Li K, Chen R, Liao Q. A review of waste heat recovery technologies towards molten slag in steel industry. Appl Energy. 2013;112:956–66. https://doi.org/10.1016/j.apenergy.2013.02.019.

Rawlings R, Wu J, Boccaccini AR. Glass-ceramics: their production from wastes – A review. J Mater Sci. 2006;41(3):733–61. Doi: https://doi.org/10.1007/s10853-006-6554-3.

Deubener J, Allix M, Davis MJ, Duran A, Höche T, Honma T, Komatsu T, Krüger S, Mitra I, Müller R, Nakane S, Pascual MJ, Schmelzer JWP, Zanotto ED, Zhou S. Updated definition of glass-ceramics. J Non-Cryst Solids. 2018;501:3–10. https://doi.org/10.1016/j.jnoncrysol.2018.01.033.

Chen H, Lin H, Zhang P, Lin Yu, Chen L, Huang X, Jiao B, Li D. Immobilisation of heavy metals in hazardous waste incineration residue using SiO2–Al2O3–Fe2O3–CaO glass-ceramic. Ceram Int. 2021;47:8468–77. https://doi.org/10.1016/j.ceramint.2020.11.213.

Ferreira NM, Sarabando AR, Atanasova-Vladimirova S, Kukeva R, Stoyanova R, Ranguelov BS, Costa FM. Iron oxidation state effect on the Mg–Al–Si–O glassy system. Ceram Int. 2019;45:21379–84. https://doi.org/10.1016/j.ceramint.2019.07.125.

Jung Ho Heo, Jung-Wook Cho, Hyun Sik Park, Joo Hyun Park. Crystallization and vitrification behavior of CaO–SiO2–FetO–Al2O3 slag: Fundamentals to use mineral wastes in production of glass ball. J Cleaner Prod. 2019;225:743–54. Doi: https://doi.org/10.1016/j.jclepro.2019.04.035.

Zhao M, Cao J, Wang Z, Li G. Insight into the dual effect of Fe2O3 addition on the crystallization of CaO–MgO–Al2O3–SiO2 glass-ceramics. J Non-Cryst Solids. 2019;513:144–51. https://doi.org/10.1016/j.jnoncrysol.2019.03.021.

Romero M, Kovacova M, Rincón JM. Effect of particle size on kinetic crystallization of an iron-rich glass. J Mater Sci. 2008;43:4135–4142.

Cedillo González EI, Ruiz Valdés JJ, Alvarez MA. Kinetics study on controlled crystallization of a Ca2ZnSi2O7 phase in materials obtained from vitrification of metallurgical slag and recycled soda lime glass. Adv Sci Technol. 2010;68:114–9. https://doi.org/10.4028/www.scientific.net/AST.68.114.

Xiao Y, Shen X, Xingrong Wu, Wang H. Vitrification and crystallization behavior of CaO–SiO2–MgO–Al2O3–Fe2O3–Cr2O3 system. Metall Trans B. 2020;51B:827–35. https://doi.org/10.1007/s11663-019-01743-5.

Henderson DW. Thermal analysis of non-isothermal crystallization kinetics in glass forming liquids. J Non-Cryst Solids. 1979;30:301–15.

Yinnon H, Uhlmann DR. Applications of thermoanalytical techniques to the study of crystallization kinetics in glass-forming liquids. Part I: Theory J Non Cryst Solids. 1983;54:253–75.

Opfermann J. NETZSCH Thermokinetics, version 2006.08. https://www.therm-soft.com. Accessed 20 April 2021.

NETZSCH Proteus Software. Thermal Analysis. Version 4.8.3. http://www.netzsch-thermal-analysis.com. Accessed 20 April 2021.

Chung FH. A new X-ray diffraction method for quantitative multicomponent analysis. Adv X-Ray Anal. 1973;17:106–15.

Hubbard CR, Evans EH, Smith DK. The reference intensity ratio, I/Ic, for computer simulated powder patterns. J Appl Crystallogr. 1976;9:169–74.

Altomare A, Corriero N, Cuocci C, Falcicchio A, Moliterni A, Rizzi R. QUALX2.0: a qualitative phase analysis software using the freely available database POW_COD. J Appl Crystallogr. 2015;48:598–603. Doi: https://doi.org/10.1107/S1600576715002319.

Mills KC, Courtney L, Fox AB, Harris B, Idoyaga Z, Richardson MJ. The use of thermal analysis in the determination of the crystalline fraction of slag films. Thermochim Acta. 2002;391:175–84.

ASTM E112–13. Standard Test Methods for Determining Average Grain Size. ASTM International, West Conshohocken, PA, 2013.

Vyazovkin S, Burnham AK, Criado JM, Perez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Arshad MA, Maaroufi AK. Recent advances in kinetics and mechanisms of condensed phase processes: a mini-review. Rev Adv Mater Sci. 2017;51:177–87.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57:217–21.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12(3):150–8.

Augis JA, Bennett JE. Calculation of the Avrami parameters for heterogeneous solid state reactions using a modification of the Kissinger method. J Therm Anal. 1978;13:283–92.

Matusita K, Sakka S. Kinetic study of crystallization of glass by differential thermal analysis—criterion on application of Kissinger plot. J Non-Cryst Solids. 1980;38–39(2):741–6.

Francis A, Vilminot S. Crystallisation kinetics of mullite glass-ceramics obtained from alumina-silica wastes. Int J Sustain Eng. 2012;6(1):1–8. https://doi.org/10.1080/19397038.2012.672478.

Mahadevan S, Giridhar A, Singh AK. Calorimetric measurements on As–Sb–Se glasses. J Non Cryst Solids. 1986;88:11–34. https://doi.org/10.1111/j.1551-2916.2005.00354.x.

Francis AA. Non-isothermal crystallization kinetics of a blast furnace slag glass. J Am Ceram Soc. 2005;88(7):1859–63.

Shi N, Dou Q. Non-isothermal cold crystallization kinetics of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/treated calcium carbonate composites. J Therm Anal Calorim. 2015;119:635–42. https://doi.org/10.1007/s10973-014-4162-z.

Hou Y, Zhang G-H, Chou K-C, Fan D. Effects of CaO/SiO2 ratio and heat treatment parameters on the crystallization behavior, microstructure and properties of SiO2–CaO–Al2O3–Na2O glass ceramics. J Non-Cryst Solids. 2020;538: 120023. https://doi.org/10.1016/j.jnoncrysol.2020.120023.

Acknowledgments

The work was carried out according to the State Assignment for IMET UB RAS.

Funding

No funding.

Author information

Authors and Affiliations

Contributions

AK contributed to conceptualization, formal analysis, and writing—original draft; RG contributed to investigation and writing—review and editing; SP contributed to investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Klyushnikov, A., Gulyaeva, R. & Pikalov, S. Cold crystallization kinetics of slag from the joint smelting of oxidized nickel and sulfide copper ores. J Therm Anal Calorim 147, 12165–12176 (2022). https://doi.org/10.1007/s10973-022-11429-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11429-x