Abstract

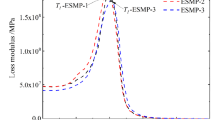

This paper presents a three-dimensional (3D) finite deformation thermomechanical model to study the glass transition and shape memory behaviors of an epoxy based shape memory polymer (SMP) (Veriflex E) and a systematic material parameter identification scheme from a set of experiments. The model was described by viscoelastic elements placed in parallel to represent different active relaxation mechanisms around glass transition temperature in the polymer. A set of standard material tests was proposed and conducted to identify the model parameter values, which consequently enable the model to reproduce the experimentally observed shape memory (SM) behaviors. The parameter identification procedure proposed in this paper can be used as an effective tool to assist the construction and application of such 3D multi-branch model for general SMP materials.

Similar content being viewed by others

Notes

The anisotropy in polymer thermal expansion could be accounted for by using additional thermal expansion components in the model.

References

Alvine, K.J., et al.: Capillary instability in nanoimprinted polymer films. Soft Matter 5, 2913–2918 (2009)

Anand, L., Kothari, M.: A computational procedure for rate-independent crystal plasticity. J. Mech. Phys. Solids 44(4), 525–558 (1996)

Arruda, E.M., Boyce, M.C.: A 3-dimensional constitutive model for the large stretch behavior of rubber elastic-materials. J. Mech. Phys. Solids 41(2), 389–412 (1993)

Barot, G., Rao, I.J., Rajagopal, K.R.: A thermodynamic framework for the modeling of crystallizable shape memory polymers. Int. J. Eng. Sci. 46(4), 325–351 (2008)

Bhattacharyya, A., Tobushi, H.: Analysis of the isothermal mechanical response of a shape memory polymer rheological model. Polym. Eng. Sci. 40(12), 2498–2510 (2000)

Buckley, P.R., et al.: Inductively heated shape memory polymer for the magnetic actuation of medical devices. IEEE Trans. Biomed. Eng. 53(10), 2075–2083 (2006)

Castro, F., et al.: Effects of thermal rates on the thermomechanical behaviors of amorphous shape memory polymers. Mech. Time-Depend. Mater. 14(3), 219–241 (2010)

Castro, F., et al.: Time and temperature dependent recovery of epoxy-based shape memory polymers. J. Eng. Mater. Technol.-Trans. ASME 133, 021025 (2011)

Chen, Y.C., Lagoudas, D.C.: A constitutive theory for shape memory polymers. Part I—large deformations. J. Mech. Phys. Solids 56(5), 1752–1765 (2008)

Chung, T., Rorno-Uribe, A., Mather, P.T.: Two-way reversible shape memory in a semicrystalline network. Macromolecules 41(1), 184–192 (2008)

Marzio, E.A., Yang, A.J.M.: Configurational entropy approach to the kinetics of glasses. J. Res. Natl. Inst. Stand. Technol. 102(2), 135–157 (1997)

Diani, J., Liu, Y.P., Gall, K.: Finite strain 3D thermoviscoelastic constitutive model for shape memory polymers. Polym. Eng. Sci. 46(4), 486–492 (2006)

Diani, J., et al.: Predicting thermal shape memory of crosslinked polymer networks from linear viscoelasticity. Int. J. Solids Struct. 49(5), 793–799 (2012)

Ding, Y., et al.: Relaxation behavior of polymer structures fabricated by nanoimprint lithography. ASC Nano 1(2), 84–92 (2007)

Engels, T.A.P., et al.: Predicting the long-term mechanical performance of polycarbonate from thermal history during injection molding. Macromol. Mater. Eng. 294(12), 829–838 (2009)

Gall, K., et al.: Thermomechanics of the shape memory effect in polymers for biomedical applications. J. Biomed. Mater. Res., Part A 73A(3), 339–348 (2005)

Ge, Q., et al.: Thermomechanical behavior of shape memory elastomeric composites. J. Mech. Phys. Solids 60(1), 67–83 (2011)

Ge, Q., et al.: Prediction of temperature-dependent free recovery behaviors of amorphous shape memory polymers. Soft Matter 8(43), 11098–11105 (2012)

Ge, Q., et al.: Mechanisms of triple-shape polymeric composites featuring dual thermal transitions. Soft Matter 9, 2212–2223 (2013)

He, Z.W., et al.: Remote controlled multishape polymer nanocomposites with selective radiofrequency actuations. Adv. Mater. 23(28), 3192 (2011)

Holzapfel, G.A.: Nonlinear Solid Mechanics: A Continuum Approach for Engineering. Wiley, New York (2000)

Huang, W.M., et al.: Water-driven programmable polyurethane shape memory polymer: demonstration and mechanism. Appl. Phys. Lett. 86, 114105 (2005)

Jiang, H.Y., Kelch, S., Lendlein, A.: Polymers move in response to light. Adv. Mater. 18(11), 1471–1475 (2006)

Jung, Y.C., So, H.H., Cho, J.W.: Water-responsive shape memory polyurethane block copolymer modified with polyhedral oligomeric silsesquioxane. J. Macromol. Sci. B, Phys. 45(4), 453–461 (2006)

Koerner, H., et al.: Remotely actuated polymer nanocomposites–stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nat. Mater. 3(2), 115–120 (2004)

Kovacs, A.J., et al.: Isobaric volume and enthalpy recovery of glasses. II. A transparent multiparameter theory. J. Polym. Sci., Polym. Phys. Ed. 17(7), 1097–1162 (1979)

Kumar, U.N., et al.: Non-contact actuation of triple-shape effect in multiphase polymer network nanocomposites in alternating magnetic field. J. Mater. Chem. 20(17), 3404–3415 (2010)

Lendlein, A., Kelch, S.: Shape-memory polymers. Angew. Chem., Int. Ed. Engl. 41(12), 2035–2057 (2002)

Lendlein, A., Kelch, S.: Shape-memory polymers as stimuli-sensitive implant materials. Clin. Hemorheol. Microcirc. 32(2), 105–116 (2005)

Lendlein, A., et al.: Light-induced shape-memory polymers. Nature 434(7035), 879–882 (2005)

Li, J.J., Xie, T.: Significant impact of thermo-mechanical conditions on polymer triple-shape memory effect. Macromolecules 44(1), 175–180 (2011)

Liu, Y.P., et al.: Thermomechanics of shape memory polymer nanocomposites. Mech. Mater. 36(10), 929–940 (2004)

Liu, Y.P., et al.: Thermomechanics of shape memory polymers: uniaxial experiments and constitutive modeling. Int. J. Plast. 22(2), 279–313 (2006)

Liu, C., Qin, H., Mather, P.T.: Review of progress in shape-memory polymers. J. Mater. Chem. 17(16), 1543–1558 (2007)

Long, K.N., et al.: Photomechanics of light-activated polymers. J. Mech. Phys. Solids 57(7), 1103–1121 (2009)

Long, K.N., et al.: Light-induced stress relief to improve flaw tolerance in network polymers. J. Appl. Phys. 107, 053519 (2010a)

Long, K.N., et al.: Photo-induced creep of network polymers. Int. J. Struct. Ch. Solids 2, 41–52 (2010b)

Long, K.N., Dunn, M.L., Qi, H.J.: Mechanics of soft active materials with phase evolution. Int. J. Plast. 26(4), 603–616 (2010c)

Long, K.N., Dunn, M.L., Qi, H.J.: Photo-induced deformation of active polymer films: single spot irradiation. Int. J. Solids Struct. 48, 2089–2101 (2011)

Mather, P.T., Luo, X.F., Rousseau, I.A.: Shape memory polymer research. Annu. Rev. Mater. Res. 39, 445–471 (2009)

McClung, A.J.W., Tandon, G.P., Baur, J.W.: Strain rate- and temperature-dependent tensile properties of an epoxy-based, thermosetting, shape memory polymer (Veriflex-E). Mech. Time-Depend. Mater. 16(2), 205–221 (2012)

McClung, A., Tandon, G., Baur, J.W.: Deformation rate-, hold time-, and cycle-dependent shape-memory performance of Veriflex-E resin. Mech. Time-Depend. Mater. 17(1), 39–52 (2013)

Mohr, R., et al.: Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers. Proc. Natl. Acad. Sci. USA 103(10), 3540–3545 (2006)

Morshedian, J., Khonakdar, H.A., Rasouli, S.: Modeling of shape memory induction and recovery in heat-shrinkable polymers. Macromol. Theory Simul. 14(7), 428–434 (2005)

Nguyen, T.D., et al.: A thermoviscoelastic model for amorphous shape memory polymers: incorporating structural and stress relaxation. J. Mech. Phys. Solids 56(9), 2792–2814 (2008)

Nguyen, T.D., et al.: Modeling the relaxation mechanisms of amorphous shape memory polymers. Adv. Mater. 22(31), 3411–3423 (2010)

Qi, H.J., Joyce, K., Boyce, M.C.: Durometer hardness and the stress–strain behavior of elastomeric materials. Rubber Chem. Technol. 76(2), 419–435 (2003)

Qi, H.J., et al.: Finite deformation thermo-mechanical behavior of thermally induced shape memory polymers. J. Mech. Phys. Solids 56(5), 1730–1751 (2008)

Rubinstein, M., Colby, R.H.: Polymer Physics. Oxford University Press, New York (2003)

Ryu, J., et al.: Photo-origami. Appl. Phys. Lett. 100, 161908 (2012)

Schmidt, A.M.: Electromagnetic activation of shape memory polymer networks containing magnetic nanoparticles. Macromol. Rapid Commun. 27(14), 1168–1172 (2006)

Scott, T.F., et al.: Photoinduced plasticity in cross-linked polymers. Science 308(5728), 1615–1617 (2005)

Scott, T.F., Draughon, R.B., Bowman, C.N.: Actuation in crosslinked polymers via photoinduced stress relaxation. Adv. Mater. 18(16), 2128 (2006)

Sherrod, P.H.: Nonlinear regression analysis program, NLREG Version 5.0. (2000). Available from http://www.nlreg.com/

Srivastava, V., Chester, S.A., Anand, L.: Thermally actuated shape-memory polymers: experiments, theory, and numerical simulations. J. Mech. Phys. Solids 58(8), 1100–1124 (2010)

Tobushi, H., et al.: Thermomechanical properties in a thin film of shape memory polymer of polyurethane series. Smart Mater. Struct. 5(4), 483–491 (1996)

Tobushi, H., Hashimoto, T., Ito, N.: Shape fixty and shape recovery in a film of shape memory polymer of polyurethane series. J. Intell. Mater. Syst. Struct. 9, 127–136 (1998)

Tool, A.Q.: Relation between inelastic deformability and thermal expansion of glass in its annealing range. J. Am. Ceram. Soc. 29(9), 240–253 (1946)

Tool, A.Q.: Effect of heat-treatment on the density and constitution of high-silica glasses of the borosilicate type. J. Am. Ceram. Soc. 31(7), 177–186 (1948)

Tool, A.Q., Eichlin, C.G.: Variations caused in the heating curves of glass by heat treatment. J. Am. Ceram. Soc. 14(4), 276–308 (1931)

Treloar, L.R.G.: The Physics of Rubber Elasticity. Monographs on the Physics and Chemistry of Materials, p. 342, 2nd edn. Clarendon Press, Oxford (1958)

Wang, A., et al.: Programmable, pattern-memorizing polymer surface. Adv. Mater. 23, 3669–3673 (2011)

Weber, G., Anand, L.: Finite deformation constitutive-equations and a time integration procedure for isotropic, hyperelastic viscoplastic solids. Comput. Methods Appl. Mech. Eng. 79(2), 173–202 (1990)

Wei, Z.G., Sandstrom, R., Miyazaki, S.: Shape-memory materials and hybrid composites for smart systems—part I shape-memory materials. J. Mater. Sci. 33(15), 3743–3762 (1998)

Westbrook, K.K., et al.: Improved testing system for thermomechanical experiments on polymers using uniaxial compression equipment. Polym. Test. 29(4), 503–512 (2010a)

Westbrook, K.K., et al.: Constitutive modeling of shape memory effects in semicrystalline polymers with Stretch induced crystallization. J. Eng. Mater. Technol.-Trans. ASME 132, 041010 (2010b)

Westbrook, K.K., et al.: A 3D finite deformation constitutive model for amorphous shape memory polymers: a multi-branch modeling approach for nonequilibrium relaxation processes. Mech. Mater. 43(12), 853–869 (2011)

Westbrook, K.K., et al.: Two-way reversible shape memory effects in a free-standing polymer composite. Smart Mater. Struct. 20, 065010 (2011)

Williams, M.L., Landel, R.F., Ferry, J.D.: Temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. Phys. Rev. 98(5), 1549 (1955)

Xie, T.: Tunable polymer multi-shape memory effect. Nature 464(7286), 267–270 (2010)

Xie, T., Xiao, X.C., Cheng, Y.T.: Revealing triple-shape memory effect by polymer bilayers. Macromol. Rapid Commun. 30(21), 1823–1827 (2009)

Yakacki, C.M., et al.: Unconstrained recovery characterization of shape-memory polymer networks for cardiovascular applications. Biomaterials 28(14), 2255–2263 (2007)

Yu, K., et al.: Carbon nanotube chains in a shape memory polymer/carbon black composite: To significantly reduce the electrical resistivity. Appl. Phys. Lett. 98, 074102 (2011)

Yu, K., et al.: Mechanisms of multi-shape memory effects and associated energy release in shape memory polymers. Soft Matter 8(20), 5687–5695 (2012)

Yu, K., et al.: Design considerations for shape memory polymer composites with magnetic particles. J. Compos. Mater. 47(1), 51–63 (2013)

Acknowledgements

H.J.Q. acknowledges the support through AFRL summer faculty fellowship program (contract FA8650-07-D-5800).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, K., McClung, A.J.W., Tandon, G.P. et al. A thermomechanical constitutive model for an epoxy based shape memory polymer and its parameter identifications. Mech Time-Depend Mater 18, 453–474 (2014). https://doi.org/10.1007/s11043-014-9237-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-014-9237-5