Abstract

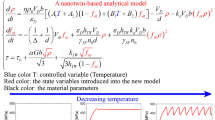

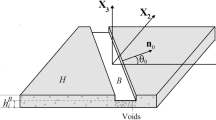

Hopf bifurcation is a common phenomenon during the metal cutting process, which results in poor surface finish of the workpiece and inhomogeneous grain structure in materials. Therefore, understanding and controlling Hopf bifurcation in metal cutting are necessary. In this work, the systematic low-speed extrusion machining experiments were conducted to suppress Hopf bifurcation phenomenon. It is found that the suppression of Hopf bifurcation is achieved with the increasing constraint extrusion degree. In order to reveal the mechanism of the suppression of Hopf bifurcation, a new nonlinear dynamic model for extrusion machining is developed where the convection, the diffusion, the extrusion of constraint, the thermal-softening deformation and the fracture-type damage are included. The theoretical predictions are in agreement with the experimental results; therefore, the present theoretical model is effective to characterize the suppression of Hopf bifurcation in metal cutting. Based on the numerical calculation of the theoretical model, the mechanisms underlying in extrusion machining are further revealed: Fracture-type deformation is more important than the thermal-softening-type deformation in low-speed extrusion machining; however, the thermal-softening-type deformation is the primary deformation mode for high-speed extrusion machining.

Similar content being viewed by others

References

Shaw, M.C.: Metal Cutting Principles, 2nd edn. Oxford University Press, Oxford (2005)

Brown, T.L., Swaminathan, S., Chandrasekar, S., Compton, W.D., King, A.H., Trumble, K.P.: Low-cost manufacturing process for nanostructured metals and alloys. J. Mater. Res. 17(10), 2484–2488 (2002). doi:10.1557/jmr.2002.0362

Cai, S.L., Chen, Y., Ye, G.G., Jiang, M.Q., Wang, H.Y., Dai, L.H.: Characterization of the deformation field in large-strain extrusion machining. J. Mater. Process. Technol. 216, 48–58 (2015). doi:10.1016/j.jmatprotec.2014.08.022

Liu, Y., Cai, S., Dai, L.: A new method for grain refinement in magnesium alloy: high speed extrusion machining. Mater. Sci. Eng. A 651, 878–885 (2016). doi:10.1016/j.msea.2015.11.046

Otto, A., Radons, G.: The influence of tangential and torsional vibrations on the stability lobes in metal cutting. Nonlinear Dyn. 82(4), 1989–2000 (2015). doi:10.1007/s11071-015-2293-9

Deng, W.J., Xia, W., Li, C., Tang, Y.: Formation of ultra-fine grained materials by machining and the characteristics of the deformation fields. J. Mater. Process. Technol. 209(9), 4521–4526 (2009). doi:10.1016/j.jmatprotec.2008.10.043

Recht, R.F.: Catastrophic thermoplastic shear. J. Appl. Mech. 31(2), 189–193 (1964)

Semiatin, S.L., Rao, S.B.: Shear localization during metal cutting. Mater. Sci. Eng. 61(2), 185–192 (1983). doi:10.1016/0025-5416(83)90200-8

Molinari, A., Dudzinski, D.: Stationary shear band in high-speed machining. C. R. Acad. Sci. Ser. 315(4), 399–405 (1992)

Burns, T.J., Davies, M.A.: Nonlinear dynamics model for chip segmentation in machining. Phys. Rev. Lett. 79(3), 447–450 (1997). doi:10.1103/PhysRevLett.79.447

Burns, T.J., Davies, M.A.: On repeated adiabatic shear band formation during high-speed machining. Int. J. Plast. 18(4), 487–506 (2002). doi:10.1016/s0749-6419(01)00006-7

Huang, J., Aifantis, E.C.: A note on the problem of shear localization during chip formation in orthogonal machining. J. Mater. Eng. Perform. 6(1), 25–26 (1997). doi:10.1007/s11665-997-0027-y

Huang, J., Kalaitzidou, K., Sutherland, J.W., Aifantis, E.C.: Validation of a predictive model for adiabatic shear band formation in chips produced via orthogonal machining. J. Mech. Behav. Mater. 18(4), 243–263 (2007)

Molinari, A., Soldani, X., Miguélez, M.H.: Adiabatic shear banding and scaling laws in chip formation with application to cutting of Ti–6Al–4V. J. Mech. Phys. Solids 61(11), 2331–2359 (2013). doi:10.1016/j.jmps.2013.05.006

Hanna, N.H., Tobias, S.A.: A theory of nonlinear regenerative chatter. ASME J. Eng. Ind. 96, 247–255 (1974)

Shi, H.M., Tobias, S.A.: Theory of finite amplitude machine tool instability. Int. J. Mach. Tool Des. Res. 24, 45–69 (1984)

Nayfeh, A.H., Chin, C.M., Pratt, J.R.: Perturbation methods in nonlinear dynamics: applications to machining dynamics. J. Manuf. Sci. Eng. 119, 485–493 (1997)

Pratt, J.R., Nayfeh, A.H.: Design and modeling for chatter control. Nonlinear Dyn. 19, 49–69 (1999)

Kalmár-Nagy, T., Stépán, G., Moon, F.C.: Subcritical Hopf bifurcation in the delay equation model for machine tool vibrations. Nonlinear Dyn. 26(2), 121–142 (2001). doi:10.1023/a:1012990608060

Nayfeh, A.H., Nayfeh, N.A.: Analysis of the cutting tool on a lathe. Nonlinear Dyn. 63(3), 395–416 (2010). doi:10.1007/s11071-010-9811-6

Ren, Q., Baron, L., Balazinski, M.: Fuzzy identification of cutting acoustic emission with extended subtractive cluster analysis. Nonlinear Dyn. 67(4), 2599–2608 (2011). doi:10.1007/s11071-011-0173-5

Moradi, H., Movahhedy, M.R., Vossoughi, G.: Bifurcation analysis of milling process with tool wear and process damping: regenerative chatter with primary resonance. Nonlinear Dyn. 70(1), 481–509 (2012). doi:10.1007/s11071-012-0470-7

Litak, G., Schubert, S., Radons, G.: Nonlinear dynamics of a regenerative cutting process. Nonlinear Dyn. 69(3), 1255–1262 (2012). doi:10.1007/s11071-012-0344-z

Elias, J., Namboothiri, V.N.N.: Cross-recurrence plot quantification analysis of input and output signals for the detection of chatter in turning. Nonlinear Dyn. 76(1), 255–261 (2013). doi:10.1007/s11071-013-1124-0

Molnár, T.G., Insperger, T., Stépán, G.: State-dependent distributed-delay model of orthogonal cutting. Nonlinear Dyn. (2015). doi:10.1007/s11071-015-2559-2

Ye, G.G., Xue, S.F., Jiang, M.Q., Tong, X.H., Dai, L.H.: Modeling periodic adiabatic shear band evolution during high speed machining Ti–6Al–4V alloy. Int. J. Plast. 40, 39–55 (2013). doi:10.1016/j.ijplas.2012.07.001

Molinari, A., Musquar, C., Sutter, G.: Adiabatic shear banding in high speed machining of Ti–6Al–4V: experiments and modeling. Int. J. Plast. 18(4), 443–459 (2002). doi:10.1016/s0749-6419(01)00003-1

Efe, M., Moscoso, W., Trumble, K.P., Dale Compton, W., Chandrasekar, S.: Mechanics of LSEM and application to deformation processing of magnesium alloys. Acta Mater. 60(5), 2031–2042 (2012). doi:10.1016/j.actamat.2012.01.018

Shankar, M.R., Rao, B.C., Lee, S., Chandrasekar, S., King, A.H., Compton, W.D.: Severe plastic deformation (SPD) of titanium at near-ambient temperature. Acta Mater. 54(14), 3691–3700 (2006). doi:10.1016/j.actamat.2006.03.056

Sheikh-Ahmad, J.Y., Quarless, V., Bailey, J.A.: On the role of microcracks on flow instability in low speed machining of CP titanium. Mach. Sci. Technol. 8(3), 415–430 (2004). doi:10.1081/lmst-200039867

Cai, S.L., Dai, L.H.: Suppression of repeated adiabatic shear banding by dynamic large strain extrusion machining. J. Mech. Phys. Solids 73, 84–102 (2014). doi:10.1016/j.jmps.2014.09.004

De Chiffre, L.: Extrusion-cutting. Int. J. Mach. Tool Des. Res. 16(2), 137–144 (1976). doi:10.1016/0020-7357(76)90032-9

Oxley, P.L.B.: Mechanics of Machining: An Analytical Approach to Assessing Machinability. Wiley, New York (1989)

Wallace, D.C.: Irreversible thermodynamics of flow in solids. Phys. Rev. B 22, 1477–1786 (1980)

Taylor, G.I., Quinney, H.: The plastic distortion of metals. Philos. Trans. R. Soc. Lond. A 230, 323–362 (1931)

Wright, T.W., Walter, J.W.: The asymptotic structure of an adiabatic shear band in antiplane motion. J. Mech. Phys. Solids 44(1), 77–97 (1996). doi:10.1016/0022-5096(95)00066-6

Bai, Y.L.: Thermo-plastic instability in simple shear. J. Mech. Phys. Solids 30(4), 195–207 (1982). doi:10.1016/0022-5096(82)90029-1

Molinari, A.: Collective behavior and spacing of adiabatic shear bands. J. Mech. Phys. Solids 45(9), 1551–1575 (1997). doi:10.1016/s0022-5096(97)00012-4

Jiang, M.Q., Dai, L.H.: On the origin of shear banding instability in metallic glasses. J. Mech. Phys. Solids 57(8), 1267–1292 (2009). doi:10.1016/j.jmps.2009.04.008

Dolinski, M., Rittel, D.: Experiments and modeling of ballistic penetration using an energy failure criterion. J. Mech. Phys. Solids 83, 1–18 (2015). doi:10.1016/j.jmps.2015.06.004

Dolinski, M., Rittel, D., Dorogoy, A.: Modeling adiabatic shear failure from energy considerations. J. Mech. Phys. Solids 58(11), 1759–1775 (2010). doi:10.1016/j.jmps.2010.08.007

Hillerborg, A., Modeer, M., Petersson, P.E.: Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 6, 773–782 (1976)

Zhang, Y.C., Mabrouki, T., Nelias, D., Gong, Y.D.: Chip formation in orthogonal cutting considering interface limiting shear stress and damage evolution based on fracture energy approach. Finite Elem. Anal. Des. 47(7), 850–863 (2011). doi:10.1016/j.finel.2011.02.016

Merchant, M.E.: Mechanics of the metal cutting process. II. Plasticity conditions in orthogonal cutting. J. Appl. Phys. 16(6), 318–324 (1945)

Merchant, M.E.: Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J. Appl. Phys. 16(5), 267–275 (1945)

Sun, S., Brandt, M., Dargusch, M.S.: Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf. 49(7–8), 561–568 (2009). doi:10.1016/j.ijmachtools.2009.02.008

Zhou, L., Peng, F.Y., Yan, R., Yao, P.F., Yang, C.C., Li, B.: Analytical modeling and experimental validation of micro end-milling cutting forces considering edge radius and material strengthening effects. Int. J. Mach. Tools Manuf. 97, 29–41 (2015). doi:10.1016/j.ijmachtools.2015.07.001

Sutter, G., List, G.: Very high speed cutting of Ti–6Al–4V titanium alloy: change in morphology and mechanism of chip formation. Int. J. Mach. Tools Manuf. 66, 37–43 (2013). doi:10.1016/j.ijmachtools.2012.11.004

Davies, M.A., Burns, T.J.: Thermomechanical oscillations in material flow during high-speed machining. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 359(1781), 821–846 (2001)

Ye, G.G., Chen, Y., Xue, S.F., Dai, L.H.: Critical cutting speed for onset of serrated chip flow in high speed machining. Int. J. Mach. Tools Manuf. 86, 18–33 (2014). doi:10.1016/j.ijmachtools.2014.06.006

Özel, T., Altan, T.: Determination of workpiece flow stress and friction at the chip-tool contact for high-speed cutting. Int. J. Mach. Tools Manuf. 40(1), 133–152 (2000). doi:10.1016/s0890-6955(99)00051-6

Komanduri, R.: Some clarifications on the mechanics of chip formation when machining titanium alloys. Wear 76(1), 15–34 (1982). doi:10.1016/0043-1648(82)90113-2

Wang, Z.H., Hu, H.Y.: Robust stability test for dynamic systems with short delays by using padé approximation. Nonlinear Dyn. 18, 275–287 (1999)

Wang, Z.H., Hu, H.Y.: Dimensional reduction for nonlinear time-delayed systems composed of stiff and soft substructures. Nonlinear Dyn. 25, 317–331 (2001)

Zhan, Z.Q., Zhu, J., Li, W.: Stability and bifurcation analysis in a FAST TCP model with feedback delay. Nonlinear Dyn. 70(1), 255–267 (2012)

Li, Y., Xu, D.: Chaotification of quasi-zero-stiffness system with time delay control. Nonlinear Dyn. 86, 353–368 (2016)

Zhang, X.J., Xiong, C.H., Ding, Y., Ding, H.: Updated numerical integration method for stability calculation of Mathieu equation with various time delays. Nonlinear Dyn. (2016). doi:10.1007/s11071-016-3096-3

Korn, G.A., Korn, T.M.: Mathermatical Handbook for Scientists and Engineers. McGraw-Hill, New York (1961)

Acknowledgements

This work has been supported by the National Natural Science Foundation of China (Grant Nos. 11132011 and 11602236), Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-15-101A1), the Opening Fund of State Key Laboratory of Nonlinear Mechanics, China Postdoctoral Science Foundation (Grant No. 2016M591066), the National Basic Research Program of China (Grant No. 2012CB937500) and the CAS/SAFEA International Partnership Program for Creative Research Teams. We are very grateful to the anonymous reviewers for their helpful comments, which have improved our manuscript significantly.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Y., Cai, S., Shang, X. et al. Suppression of Hopf bifurcation in metal cutting by extrusion machining. Nonlinear Dyn 88, 433–453 (2017). https://doi.org/10.1007/s11071-016-3251-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-016-3251-x