Abstract

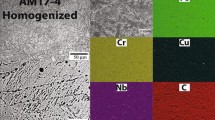

An oxidation treatment is often performed on austenitic stainless steel prior to joining to alkali barium silicate glass to produce hermetic seals. The thin oxide formed during this pre-oxidation step acts as a transitional layer and a source of Cr and other elements that diffuse into the glass during the subsequent bonding process. Pre-oxidation is performed in a low pO2 atmosphere to avoid iron oxide formation; the final oxide is composed of Cr2O3, MnCr2O4 spinel, and SiO2. Significant heat-to-heat variations in the oxidation behavior of austenitic stainless steel were observed in this work, resulting in inconsistent glass/metal seal behavior. Twenty-five (25) stainless steel heats were examined including 304L, 316L, and experimental high sulfur alloys similar to 303SS. The objectives were to characterize the oxidation kinetics, the oxide morphologies, and compositions that affect glass/metal adhesion. It was found that poor glass sealing is associated with a more continuous layer of SiO2 at the metal/oxide interface. The effects of alloy chemistry, in particular Mn and Si concentrations, on glass/metal sealing behavior were empirically determined. A criterion based on the Mn/Si ratio was developed for use in selecting heats with good glass/metal bonding characteristics. To test this criterion, four other austenitic stainless steels were evaluated: 21-6-9 (also known by original Armco Steel Co. trade name Nitronic® 40), 22-13-5 (Nitronic® 50), Nitronic® 60, and Gall-Tough® (Carpenter Technology Corp.). These alloys have compositions significantly different from 300-series alloys, but they were still found to comply with the compositional guidelines developed for predicting glass/metal adhesion.

Similar content being viewed by others

References

I. W. Donald, Glass-To-Metal Seals (Society of Glass Technology, Sheffield, UK, 2007).

I. W. Donald, Journal of Materials Science 28, 2841 (1993).

J. A. Pask and A. P. Tomsia, in Engineered Materials Handbook, Vol. 4, Ceramics and Glasses, S. J. Schneider (Vol. Chair), R. E. Loehman (Joining Section Chair) (ASM International, 1991), p. 482.

A. P. Tomsia, J. A. Pask, and R. E. Loehman, in Engineered Materials Handbook, Vol. 4, Ceramics and Glasses, S. J. Schneider (Vol. Chair), R. E. Loehman (Joining Section Chair) (ASM International, 1991), p. 493.

C. J. Leedecke, P. C. Baird, and K. D. Orphanides, in Electronic Materials Handbook (ASM International, Materials Park, OH, 1989), p. 455.

M. Mantel, Journal of Non-Crystalline Solids 273, 294 (2000).

D. F. Susan, J. A. Van Den Avyle, S. L. Monroe, N. R. Sorensen, B. B. McKenzie, J. R. Michael, J. E. Christensen, and C. A. Walker, in 3rd Int. Brazing and Soldering Conference (ASM International, San Antonio, TX, April 2006), p. 104.

D. F. Susan, J. A. Van Den Avyle, S. L. Monroe, N. R. Sorensen, B. B. McKenzie, J. R. Michael, J. E. Christensen, and C. A. Walker, in Proc. 30th Int. Conf. Adv. Ceramics and Composites (2006), ed. R. Tandon (John Wiley and Sons Inc, Cocoa Beach, FL, 2007), p. 145.

G. J. Yurek, D. Eisen, and A. Garratt-Reed, Metallurgical Transactions A 13A, 473 (1982).

F. H. Stott, G. J. Gabriel, F. I. Wei, and G. C. Wood, Werkstoffe und Korrosion 38, 521 (1987).

F. H. Stott, F. I. Wei, and C. A. Enahoro, Werkstoffe und Korrosion 40, 198 (1989).

H. Fujikawa, J. Murayama, N. Fujino, and T. Moroishi, The Sumitomo Search 31, 63 (1985).

M. D. Merz, Metallurgical Transactions A 10A, 71 (1979).

M. Shindo and T. Kondo, Tetsu-To-Hagane (J. Iron and Steel Inst. Japan) 68, 1628 (1982).

S.-H. Park, Y.-Y. Lee, Y.-D. Lee, and K.-Y. Kim, Proceedings of Microscopy of Oxidation 3, 551 (1997).

S. N. Basu and G. J. Yurek, Oxidation of Metals 36, 281 (1991).

J. S. Dunning, D. E. Alman, and J. C. Rawers, Oxidation of Metals 57, 409 (2002).

H. Fujikawa, T. Morimoto, Y. Nishiyama, and S. B. Newcomb, Oxidation of Metals 59, 23 (2003).

E. A. Gulbransen and K. F. Andrew, Journal of the Electrochemical Society 109, 560 (1962).

D. C. Kothari, L. Guzman, E. Voltolini, M. Dapor, A. Tomasi, S. Gialanella, and P. Scardi, Materials Science and Engineering A A116, 89 (1989).

Z. Kubes, J. Vesela, and Z. Weiss, Journal of Materials Science Letters 14, 876 (1995).

A. Sabioni, A.-M. Huntz, E. Coceicao da Luz, M. Mantel, and C. Haut, Materials Research 6, 179 (2003).

D. P. Whittle and G. C. Wood, Journal of the Electrochemical Society 114, 986 (1967).

R. K. Wild, Corrosion Science 17, 87 (1977).

A. Paul, S. Elmrabet, F. J. Ager, J. A. Odriozola, M. A. Respaldiza, M. F. da Silva, and J. C. Soares, Oxidation of Metals 57, 33 (2002).

AMS 2700B, Aerospace Materials Specification (Society of Automotive Engineers, 2004).

R. E. Loehman and P. G. Kotula, Journal of the American Ceramic Society 87, 55 (2004).

D. G. Lees, Oxidation of Metals 27, 75 (1987).

A. Paul, R. Sanchez, O. M. Montes, and A. J. Odriozola, Oxidation of Metals 67, 87 (2007).

M. J. Bennet, J. A. Desport, and P. A. Labun, Oxidation of Metals 22, 291 (1984).

M. J. Bennett, D. J. Buttle, P. D. Colledge, J. B. Price, C. B. Scruby, and K. A. Stacey, Materials Science and Engineering A A120, 199 (1989).

T. Adachi and G. H. Meier, Oxidation of Metals 27, 347 (1987).

Y. Saito, T. Maruyama, and T. Amano, Materials Science and Engineering 87, 275 (1987).

F. H. Stott, G. C. Wood, and J. Stringer, Oxidation of Metals 44, 113 (1995).

D. L. Douglass and J. S. Armijo, Oxidation of Metals 2, 207 (1970).

A. Kumar and D. L. Douglass, Oxidation of Metals 10, 1 (1976).

H. E. Evans, D. A. Hilton, R. A. Holm, and S. J. Webster, Oxidation of Metals 19, 1 (1983).

B. Li and B. Gleeson, Oxidation of Metals 65, 101 (2006).

D. F. Susan, M. J. Perricone, C. V. Robino, J. R. Michael, B. B. McKenzie, and M. Rodriguez, in Joining of Advanced and Specialty Materials IX, Mat. Sci. Tech. 2007 (ASM International, Detroit, MI, 2007).

Acknowledgements

The authors would like to thank MicroMode Products Inc., El Cajon, CA, for glass/metal seal processing expertise. Thanks also to Alice Kilgo for metallographic sample preparation, Mark Reece for sample preparation for oxidation and sessile drop tests, and Mark Rodriguez for X-ray diffraction analysis and interpretation. The careful review of the manuscript by Dr. M. J. Perricone is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Sandia National Laboratories—Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the US Dept. of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000.

Rights and permissions

About this article

Cite this article

Susan, D.F., Van Den Avyle, J.A., Monroe, S.L. et al. The Effects of Pre-Oxidation and Alloy Chemistry of Austenitic Stainless Steels on Glass/Metal Sealing. Oxid Met 73, 311–335 (2010). https://doi.org/10.1007/s11085-009-9181-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-009-9181-y