Abstract

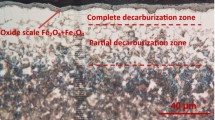

The reduction behaviour of wustite-type iron oxide scale on a low-carbon, low-silicon steel by dissolved carbon in the steel at 650–900 °C under pure nitrogen was studied. It was found that dissoved carbon in the steel examined was able to react with the wustite scale on the surface, leading to reduction of this scale. It was also found that the scale reduction rate was the most rapid within 750–800 °C, followed by that at 700 °C and then at 850 °C, whereas the rates were essentially zero at 650 and 900 °C. Decarburization occurred to the steel as a result of scale reduction, and the degree of decarburization at 750–800 °C was also the most severe. The rate of scale–carbon reaction was primarily controlled by carbon diffusion through the decarburization layer as the calculated carbon permeability, defined as the product of carbon diffusivity and the carbon concentration difference across the decarburization layer, also reached its maximum within 750–800 °C. Scale reduction led to the formation of pores at the scale–steel interface as a result of volume shrinkage when wustite was reduced to iron, but the porosity volume was smaller than calculated at 800–850 °C, which could have an inhibiting effect on the scale–carbon reaction. The calculated volume of CO + CO2 gases generated as a result of scale–carbon reactions was about 100 times the calculated porosity volume. It was believed that the wustite scale was permeable to CO and/or CO2, allowing the much larger volume of CO and CO2 gases to escape through the scale layer.

Similar content being viewed by others

References

R. Y. Chen, Mechanism of iron oxide scale reduction in 5%H2–N2 gas at 650–900 °C, Oxidation of Metals, Published on line 12 April 2017.

R. Y. Chen and W. Y. D. Yuen, Oxidation of Metals 56, 89 (2001).

R. Y. Chen and W. Y. D. Yuen, Iron & Steekmaker 30(3), 17 (2003).

R. Y. Chen and W. Y. D. Yuen, Metallurgical and Materials Transactions A 40A, 3091 (2009).

R. F. Mehl and C. Wells, AIME Transaction 125, 429 (1937).

H. A. Wriedt, in Binary Alloy Phase Diagrams, vol. 2, 2nd ed, eds. T. B. Massalski, H. Okamoto, P. R. Subramanian and L. Kacprzak (ASM International, Metals Park, 1990), p. 1739.

R. Smith, Transactions of the Metallurgical Society 224, 105 (1962).

M. Hasebe, H. Ohtani and T. Nishizawa, Metallurgical Transactions 16A, 913 (1985).

J. A. Lobo and G. H. Gaiger, Metallurgical Transactions 7A, 1347 (1976).

S. Ban-Ya, J. Elliot and J. Chipman, Metallurgical Transactions 1, 1313 (1970).

H. Okamoto, Journal of Phase Equilibria 13, 543 (1992).

R. Naraghi, M. Selleby and J. Ågren, Calphad: Computer Coupling of Phase Diagrams and Thermochemistry 46, 148 (2014).

PandatTM, Thermodynamic Calculations and Kinetic Simulations. CompuTherm, LLC: Middleton, WI 53562, USA. www.computherm.com.

A. Jablonka, K. Harste and K. Schwerdtfeger, Steel Research 62, 24 (1991).

K. Arimoto, D. Lambert, G. Li, A. Arvind, and W. T. Wu, in Heat Treating 1998: Proceedings of the 18th Conference, eds. R. A. Wallis, H. W. Walton (ASM International, 1999), p. 639.

F. D. Richardson and J. H. E. Jeffes, Journal of the Iron and Steel Institute 160, 261 (1948).

O. Kubaschewski and C. B. Alcock, Metallurgical Thermochemistry, 5th ed, (Pergamon Press, Oxford, 1979), p. 379.

T. Ellis, I. M. Davidson and C. Bodsworth, I. ISI 201, 582 (1963).

T. Wada, H. Wada, J. F. Elliott and J. Chipman, Metallurgical Transactions 3, 1657 (1972).

D. R. Poirier, Transactions of the Metallurgical Society of AIME 242, 685 (1968).

J. A. Lobo and G. H. Geiger, Metallurgical Transactions A 7A, 1359 (1976).

G. Parrish and G. S. Harper, Production Gas Carburizing, (Pergamon Press, Oxford, 1985), p. 116.

N. Birks, in Decarburization—the proceedings of the one-day conference on decarburization organized jointly by the Heat Treatment Joint Committee of the Iron and Steel Institute, The Institute of Metals, and the Sheffield Metallurgical and Engineering Association, and held at the Inter-Group Laboratories of the BSC (BISRA) Sheffield, on October 28th 1969 (ISI Publication 133, The Iron and Steel Institute, London, 1970), p. 1.

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd Edition, (Cambridge University Press, Cambridge, 2006), 151–158, 176–178, and 309–312.

Y. Prawoto, M. A. Mat Yajid and K. J. Lee, Journal of King Saud University-Engineering Sciences 25, 141 (2013).

W. C. Leslie, The Physical Metallurgy of Steels, (McGraw-Hill Book Company, New York, 1981), p. 81.

K. Sachs and C. W. Tuck, Surface Oxidation of Steel in Industrial Furnaces, (ISI Publiscations 111: Reheating for Hot Rolling, The Iron and Steel Institute, London, 1968), pp. 1–17.

N. Birks and W. Jackson, Journal of the Iron and Steel Institute 208, 81 (1970).

W. W. Webb, J. T. Norton and C. Wagner, Journal of Electrochemical Society 103, 112 (1956).

K. Sachs and J. R. Brown, Journal of the Iron and Steel Institute 190, 169 (1958).

R. Y. Chen and W. Y. D. Yuen, Oxidation of Metals 59, 433 (2003).

H. E. Cleaves and J. M. Hiegel, Journal of Research National Bureau of Standards 28, 643 (1942).

R. Y. Chen and W. Y. D. Yuen, in Developments in High-Temperature Corrosion and Protection of Materials, eds. W. Gao and Z. Li (Woodhead Publishing Limited, Cambridge, 2008), p. 192.

H.-J. Engell and K. Bohnenkamp, in First International Congress on Metallic Corrosion, London, 10–15 April, 1961, Paper III.5 (Butterworths, London, 1962), p. 215.

Acknowledgements

Permission from the management of BlueScope Limited for publication of the information contained in this paper is gratefully acknowledged. Dr Andrew Dixon at BlueScope Limited had kindly reviewed the manuscript of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, R.Y. Reduction of Wustite Scale by Dissolved Carbon in Steel at 650–900 °C. Oxid Met 89, 1–31 (2018). https://doi.org/10.1007/s11085-017-9810-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-017-9810-9