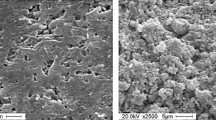

The slag corrosion and penetration behaviors of MgAl2O4, MgAl2O4–ZrO2, MgAl2O4–ZrO2–CaO, Al2O3, and Al2O3–ZrO2–SiC refractories were investigated using the static crucible method at 1873 K for 2 h. The above refractories all displayed excellent slag corrosion resistance, and their corrosion depth was less than 1.10 mm. Al2O3 material was hardly corroded by the molten slag, and its corrosion depth was only 0.05 mm. Their penetration depth ranged from 13.79 to 24.48 mm. Among them, Al2O3–ZrO2–SiC refractories displayed good slag penetration resistance with a penetration depth of 13.79 mm.

Similar content being viewed by others

References

B. Q. Zhu, Y. N. Zhu, X. C. Li, and F. Zhao, “Effect of ceramic bonding phases on the thermo-mechanical properties of Al2O3–C refractories,” Ceram. Int., 39(6), 6069 – 6076 (2013).

Q. H. Wang, Y. W. Li, M. Luo, S. B. Sang, T. B. Zhu, and L. Zhao, “Strengthening mechanism of grapheme oxide nanosheets for Al2O3-C refractories,” Ceram. Int., 40(1), 163 – 172 (2014).

B. Y. Ma, Q. Zhu, Y. Sun, J. K. Yu, and Y. Li, “Synthesis of Al2O3-SiC composite and its effect on the properties of low-carbon MgO–C refractories,” J. Mater. Sci. Technol., 26(8), 715 – 720 (2010).

I. Ganesh, S. Bhattacharjee, B. P. Saha, R. Johnson, and Y. R. Mahajan, “A new sintering aid for magnesium aluminate spinel,” Ceram. Int., 27(7), 773 – 779 (2001).

B. Y. Ma, Y. Li, Q. Zhu, G. Q. Liu, and J. K. Yu, “Preparation and properties of low-carbon Al2O3–ZrO2–SiC–C composite refractories containing LaAl11O18 ceramic phase,” Refract. Ind. Ceram., accepted (2014).

I. Gómez, M. Hernández, J. Aguilar, and M. Hinojosa, “Comparative study of microwave and conventional processing of MgAl2O4-based materials,” Ceram. Int., 30(6), 893 – 900 (2004).

Z. I. Zaki, N. Y. Mostafa, and M. M. Rashad, “High pressure synthesis of magnesium aluminate composites with MoSi2 and Mo5Si3 in a self-sustaining manner,” Ceram. Int., 38(6), 5231 – 5237 (2012).

B. Y. Ma, Y. Li, S. G. Cui, and Y. C. Zhai, “Preparation and sintering properties of zirconia-mullite-corundum composites using fly ash and zircon,” T. Nonferrous Met. Soc., 20(12), 2331 – 2335 (2010).

R. Naghizadeh, H. R. Rezaie, and F. Golestani-Fard, “Effect of TiO2 on phase evolution and microstructure of MgAl2O4 spinel in different atmospheres,” Ceram. Int., 37(1), 349 – 354 (2011).

B. Sahin and C. Aksel, “Developments on the mechanical properties of MgO-MgAl2O4 composite refractories by ZrSiO4 – 3 mol% Y2O3 addition,” J. Eur. Ceram. Soc., 32(1), 49 – 57 (2012).

C. Aksel and T. Aksoy, “Improvements on the thermal shock behaviour of MgO-spinel composite refractories by incorporation of zircon-3 mol% Y2O3,” Ceram. Int., 38(5), 3673 – 3681 (2012).

H. S. Tripathi, S. Singla, and A. Ghosh, “Synthesis and densification behaviour of magnesium aluminate spinel: Effect of Dy2O3,” Ceram. Int., 2009, 35(6), 2541 – 2544 (2009).

B. Fernández, J. M. Almanza, J. L. Rodríguez, D. A. Cortes, J. C. Escobedo, and E. J. Gutiérrez, “Corrosion mechanisms of Al2O3/MgAl2O4 by V2O5, NiO, Fe2O3 and vanadium slag,” Ceram. Int., 37(8), 2973 – 2979 (2011).

M. K. Cho, G. G. Hong, and S. K. Lee, “Corrosion of spinel clinker by CaO–Al2O3–SiO2 ladle slag,” J. Eur. Ceram. Soc., 22(11), 1783 – 1790 (2002).

J. Berjonneau, P. Prigent, and J. Poirier, “The development of a thermodynamic model for Al2O3–MgO refractory castable corrosion by secondary metallurgy steel ladle slags,” Ceram. Int., 35(2), 623 – 635 (2009).

B. A. Vázquez, P. Pena, A. H. de Aza, M. A. Sainz, and A. Caballero, “Corrosion mechanism of polycrystalline corundum and calcium hexaluminate by calcium silicate slags,” J. Eur. Ceram. Soc., 29(8), 1347 – 1360 (2009).

B. Y. Ma, Q. Zhu, Y. Sun, J. K. Yu, and Y. Li, “Influences of commercial SiC and Al2O3-SiC synthesized from clay on the slag resistance of corundum material,” Adv. Mater. Res., 146 – 147, 526 – 529 (2011).

Z. Y. Chen, “Chemical Thermodynamics of Refractories (in Chin.)”, 1st ed., Metallurgical Industry Press, Beijing, 2005.

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities (No. N120402006), the open fund for the State Key Laboratory of Refractories and Metallurgy (Wuhan University of Science and Technology) (No. G201402), the National Natural Science Foundation of China (No. 51474057), and the National High-tech R&D Program (863 Program) of China (No. 2013AA030902).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Novye Ogneupory, No. 9, pp. 38 – 44, September 2015.

Rights and permissions

About this article

Cite this article

Ma, B., Yin, Y., Zhu, Q. et al. Slag Corrosion and Penetration Behaviors of MgAl2O4 and Al2O3 Based Refractories. Refract Ind Ceram 56, 494–501 (2016). https://doi.org/10.1007/s11148-016-9876-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9876-y