Abstract

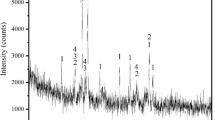

To explore the influence of thermal activation and particle size on cementitious activity of bauxite tailings, in this study, the raw bauxite tailings were classified into coarse bauxite tailings (CBT) and fine bauxite tailings (FBT) by a powder separator, and then the effect of activation temperature on cementitious activity of CBT and FBT was investigated. XRD, TG, and FTIR were used to study the phase and structure changes of CBT and FBT during the process of thermal activation. The results show that the main mineral phases of CBT and FBT, diaspore and kaolinite, begin to remove a large amount of hydroxyl groups at 500 ℃ and convert into corundum and metakaolin, respectively. The diaspore and kaolinite have completely removed the hydroxyl groups at 600 °C and 700 °C, respectively. With the increase of activation temperature, the particle size of CBT and FBT are first gradually decreased, when the activation temperature exceeds 700 ℃, as the activation temperature continues to arise, the particle size of CBT and FBT are gradually increased due to the occurrence of sintering. The activity index of bauxite tailings is increased with the increase of fineness, and the optimum activation temperature of CBT and FBT is 700 °C. When the activation temperature is the same, FBT has higher pozzolanic activity than CBT.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

ASTM (2003) C618 Standard specification for fly ash and raw or calcined natural pozzolan for use as a mineral admixture in Portland cement concrete, West Conshohocken (USA)

Barbhuiya S, Mukherjee S, Nikraz H (2014) Effects of nano-Al2O3 on early-age microstructural properties of cement paste. Constr Build Mater 52:189–193

Fang YF, Chang J (2015) Microstructure changes of waste hydrated cement paste induced by accelerated carbonation. Constr Build Mater 76:360–365

Frias M, de Rojas MIS, Garcia R, Valdes AJ, Medina C (2012) Effect of activated coal mining wastes on the properties of blended cement. Cement Concrete Comp 34:678–683

Fu LY, Zhang ZS, Lou DM, Li TC (2007) study on preparation of concrete incorporated material by activation of tailing of flotation bauxite. Chem Eng (China) 35:41–44. (in chinese)

Gou MF, Zhou LF, Then NWY (2019) Utilization of tailings in cement and concrete: A review. Sci Eng Compos Mater 26:449–464

Gu K, Jin F, Al-Tabbaa A, Shi B, Liu J (2014) Mechanical and hydration properties of ground granulated blastfurnace slag pastes activated with MgO-CaO mixtures. Constr Build Mater 69:101–108

Huang B, Feng QM, An DB, Zhang JH (2020) Use of mine tailings as precast construction materials through alkali activation. Mining Metall Explor 37:251–265

Kouamo HT, Elimbi A, Mbey JA, Sabouang CJN, Njopwouo D (2012) The effect of adding alumina-oxide to metakaolin and volcanic ash on geopolymer products: A comparative study. Constr Build Mater 35:960–969

Li DX, Song XY, Gong CC, Pan ZH (2006) Research on cementitious behavior and mechanism of pozzolanic cement with coal gangue. Cement Concrete Res 36:1752–1759

Li ZF, Gao YF, Zhang J, Zhang C, Chen JP, Liu C (2021) Effect of particle size and thermal activation on the coal gangue based geopolymer. Mater Chem Phys 267. https://doi.org/10.1016/j.matchemphys.2021.124657

Liu DX, Huang Y, Hu JY, Feng QM, Xiao JH (2021) Thermal activation mechanism and pozzolanic activity characteristics of coal flotation tailing. Adv Cem Res 33:145–155

Lodeiro IG, Macphee DE, Palomo A, Fernandez-Jimenez A (2009) Effect of alkalis on fresh C-S-H gels. FTIR Anal Cem Concr Res 39:147–153

Lu QH, Hu YH (2013) Whitening of bauxite tailings. Powder Technol 235:136–139

Luo YP, Bao SX, Zhang YM (2020) Preparation of one-part geopolymeric precursors using vanadium tailing by thermal activation. J Am Ceram Soc 103:779–783

De Magalhaes LF, Franca S, Oliveira MD, Peixoto RAF, Bessa SAL, Bezerra ACD (2020) Iron ore tailings as a supplementary cementitious material in the production of pigmented cements. J Clean Prod 274

Perumal P, Kiventera J, Illikainen M (2021) Influence of alkali source on vproperties of alkali activated silicate tailings. Mater Chem Phys 271

Qiang ZQ, Shen XJ, Guo M, Cheng FQ, Zhang M (2019) A simple hydrothermal synthesis of zeolite X from bauxite tailings for highly efficient adsorbing CO2 at room temperature. Micropor Mesopor Mat 287:77–84

Ren YH, Ren Q, Wu XL, Zheng JL, Hai O (2019) Mechanism of low temperature sintered high-strength ferric-rich ceramics using bauxite tailings. Mater Chem Phys 238

Santhanam M, Cohen MD, Olek J (2003) Effects of gypsum formation on the performance of cement mortars during external sulfate attack. Cem Concr Res 33:325–332

Scrivener KL, Fullmann A, Gallucci E, Walenta G, Bermejo E (2004) Quantitative study of Portland cement hydration by X-ray diffraction/Rietveld analysis and independent methods. Cement Concrete Res 34:1541–1547

Souri A, Kazemi-Kamyab H, Snellings R, Naghizadeh R, Golestani-Fard F, Scrivener K (2015) Pozzolanic activity of mechanochemically and thermally activated kaolins in cement. Cem Concr Res 77:47–59

Wang YH, Lan Y, Hu YH (2008) Adsorption mechanisms of Cr(VI) on the modified bauxite tailings. Miner Eng 21:913–917

Wu PX (2005) existing status of interlayer water in vermiculite mineral material. J Chin Ceram Soc 33 209–214. (in Chinese)

Wu B, Ye G (2017) Development of porosity of cement paste blended with supplementary cementitious materials after carbonation. Constr Build Mater 145:52–61

Xiao J, Li FC, Zhong QF, Bao HG, Wang BJ, Huang JD, Zhang YB (2015) Separation of aluminum and silica from coal gangue by elevated temperature acid leaching for the preparation of alumina and SiC. Hydrometallurgy 155:118–124

Yang HZ, Chen CP, Pan LJ, Lu HX, Sun HW, Hu X (2009) Preparation of double-layer glass-ceramic/ceramic tile from bauxite tailings and red mud. J Eur Ceram Soc 29:1887–1894

Yang YC, Chen LQ, Mao YG (2021) Different effects of wet and dry grinding on the activation of iron ore tailings. J Renew Mater 9:2261–2276

Yang MJ, Sun JH, Dun CY, Duan YJ, Meng ZL (2020) Cementitious activity optimization studies of iron tailings powder as a concrete admixture. Constr Build Mater 265

Ye JY, Zhang WS, Shi D (2014) Effect of elevated temperature on the properties of geopolymer synthesized from calcined ore-dressing tailing of bauxite and ground-granulated blast furnace slag. Constr Build Mater 69:41–48

Yi ZL, Sun HH, Wei XQ, Li C (2009) Iron ore tailings used for the preparation of cementitious material by compound thermal activation. Int J Min Met Mater 16:355–358

Zhang N, Sun HH, Liu XM, Zhang JX (2009) Early-age characteristics of red mud-coal gangue cementitious material. J Hazard Mater 167:927–932

Zhang YS, Zhang J, Wu L, Tan L, Xie F, Cheng JG (2021) Extraction of lithium and aluminium from bauxite mine tailings by mixed acid treatment without roasting. J Hazard Mater 404

Zhou ZJ, Chen DZ (1999) The properties and evolution of illite at high temperature. J Miner Petrol 19:20–22 (in Chinese)

Zhou SX, Dong JL, Yu LH, Xu CJ, Jiao XK, Wang MY (2019) Effect of activated coal gangue in North China on the compressive strength and hydration process of cement. J Mater Civil Eng 31

Zhou LF, Gou MF, Guan XM (2021a) Hydration kinetics of cement-calcined activated bauxite tailings composite binder. Constr Build Mater 301

Zhou LF, Gou MF, Luo SQ, (2021b) Hydration kinetics of a calcination activated bauxite tailings-lime-gypsum ternary system. J Build Eng 38

Funding

This work was supported by the National Natural Science Foundation of China (U1704148, U1905216).

Author information

Authors and Affiliations

Contributions

Longfei Zhou: investigation, data curation, formal analysis, writing—original draft. Mifeng Gou: validation, review and editing, project administration. Wenli Hou: investigation. Mengke Zhao: investigation. Jinhui Zhao: investigation. Zhaoliang Shen: investigation.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: George Z. Kyzas

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The bauxite tailings are treated with thermally activated after being classified by a powder separator.

• The optimum activation temperature of CBT and FBT is 700 °C.

• The reactivity of tailings is increased with the increase of tailings fineness.

• Activated fine tailings can be used active additive in cement.

Rights and permissions

About this article

Cite this article

Zhou, L., Gou, M., Hou, W. et al. Effect of thermal activation and particle size on cementitious activity of bauxite tailings. Environ Sci Pollut Res 29, 78960–78972 (2022). https://doi.org/10.1007/s11356-022-21409-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-21409-1