Abstract

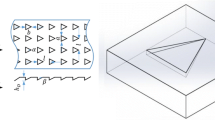

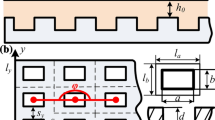

Surface texturing has been considered as an effective approach to improve the tribological performances. Based on the consideration of enhancing the tribological performance, the experiments are carried out to investigate tribological performance of triangular textures in water lubrication. The textures are generated by the Nd:YAG laser marking system, with an area density of 20% and a depth of 7 μm and are distributed uniformly on the surface of the SiC rings. Compared with the circular textures, the triangular textures have obvious tribological anisotropy. The triangular textures in clockwise direction show the best friction reduction effect among the three textures. The friction reduction mechanisms of the triangular textures in clockwise direction are also analyzed and discussed.

Similar content being viewed by others

References

Etsion I. State of the art in laser surface texturing. ASME J Tribol, 2005, 127: 248–253

Yu X Q, He S, Cai R L. Frictional characteristics of mechanical seals with a laser-textured seal face. J Mater Process Technol, 2002, 129: 463–466

Etsion I, Halperin G, Brizmer V, et al. Experimental investigation of laser surface textured parallel thrust bearings. STLE Tribol Lett, 2004, 17: 295–300

Etsion I, Burstein L. A model for mechanical seals with regular micro surface structure. STLE Tribol Trans, 1996, 39: 677–683

Etsion I, Halperin G, Greenberg Y. Increasing mechanical seals life with laser-textured seal faces. In: the 15th International Conference on Fluid Sealing BHR Group, Maastricht, the Netherlands, 1997. 3–11

Etsion I, Kligerman Y. Analytical and experimental investigation of laser-textured mechanical seal faces. STLE Tribol Trans, 1999, 42: 511–516

Wang X, Kato K, Adachi K, et al. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol Int, 2003, 36: 189–197

Brizmer V, Kligerman Y, Etsion I. A laser surface textured parallel thrust bearing. STLE Tribol Trans, 2003, 46: 397–403

Bai S X, Peng X D, Li Y F, et al. A hydrodynamic laser surface textured gas mechanical face seal. STLE Tribol Lett, 2010, 38: 187–194

Marian V G, Kilian M, Scholz W. Theoretical and experimental analysis of a partially textured thrust bearing with square dimples. Proc Inst Mech Eng Part J-J Eng Tribol, 2007, 221: 771–778

Uehara Y, Wakuda M, Yamauchi Y, et al. Tribological properties of dimpled silicon nitride under oil lubrication. J Eur Ceram Soc, 2004, 24: 369–373

Nanbu T, Ren N, Yasuda Y, et al. Microtextures in concentrated conformal-contact lubrication: Effects of texture bottom shape and surface relative motion. STLE Tribol Lett, 2008, 29: 241–252

Siripuram R, Stephens L S. Effect of deterministic asperity geometry on hydrodynamic Lubrication. ASME J Tribol, 2004, 126: 527–534

Yu H W, Wang X L, Zhou F. Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. STLE Tribol Lett, 2010, 37: 123–130

Yu H, Deng H, Huang W, et al. The effect of dimple shapes on friction of parallel surfaces. Proc Inst Mech Eng Part J-J Eng Tribol, 2011, 225: 693–703

Bai S X, Peng X D, Li J Y, et al. Experimental study on hydrodynamic effect of orientation micro-pored surfaces. Sci China-Technol Sci, 2011, 54: 659–662

Chang W R, Etsion I, Bogy D B. An elastic-plastic model for the contact of rough surfaces. ASME J Tribol, 1987, 109: 257–263

Patir N, Cheng H S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. ASME J Lubr Technol, 1978, 100: 12–17

Patir N, Cheng H S. Application of the average flow model to lubrication between rough sliding surfaces. ASME J Lubr Technol, 1979, 101: 220–229

Kumar A, Booker J F. A finite element cavitation algorithm. ASME J Tribol, 1991, 113: 276–286

Broman G I. Implications of cavitation in individual grooves of spiral groove bearings. Proc Inst Mech Eng Part J-J Eng Tribol, 2001, 215: 417–424

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, Y., Li, Y., Wang, Y. et al. An experimental investigation of tribological performance of triangular textures in water lubrication regime. Sci. China Phys. Mech. Astron. 57, 273–279 (2014). https://doi.org/10.1007/s11433-013-5254-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-013-5254-7