Abstract

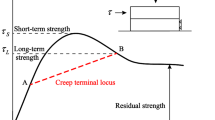

Based on previously proposed surface roughness description parameters (k a, θs, SRs, DRr, a 0), two generalized rock joint surface roughness degradation models were proposed to predict the variation of joint surface degradation during shearing under both constant normal stress (CNS) and constant normal stiffness (CNK) loading conditions. The first model was developed based on the evolution of secondary roughness (an extension of an existing model) and the second was developed based on the concept of “average asperity probable contact angle.” Model variables can be initial normal stress (σn0; k n ≥ 0), normal stiffness (k n; σn0 ≥ 0), accumulated shear displacement u s-tot (monotonic or cyclic shearing), and surface roughness amplitude a 0. Good agreement between experimental and predicted degradation was observed. The models also allow prediction of surface degradation in large-scale shear fractures. Both models are semi-incremental, readily implemented in a numerical code, and adaptable to existing elastoplastic joint behavior models.

Similar content being viewed by others

References

Amadei B, Saeb S (1990) Constitutive models of rock joints. In: Barton N, Stephansson O (eds) Rock joints. Proceedings of the international symposium on rock joints, Loen, Norway, 4–6 June 1990. Balkema, Rotterdam, pp 581–594

Amadei B,Wibowo J, Sture S, Price RH (1998) Applicability of existing models to predict the behavior of replicas of natural fractures of welded tuff under different boundary condition. Geotech Geo Eng 16(2):79–128

Archard JF (1953) Contact and rubbing of flat surfaces. J Appl Phys 24:981–988

Babadagli T, Develi K (2003) Fractal characteristics of rocks fractured under tension. Theor Appl Fract Mech 39:73–88

Barton N, Bandis S, Bakhtar K (1985) Strength, deformation and conductivity coupling of rock joints. Int J Rock Mech Min Sci Geomech Abstr 22:121–140

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Belem T (1997) Morphology and mechecanical behavior of rock discontinuities (French). Ph.D. thesis, Institut National Polytechnique de Lorraine (INPL), France, 220p

Belem T, Homand F, Souley M (2001) Characterization of sheared joint surfaces degradation. Proceedings of the 54th Canadian geotechnical conference 2001: an earth odyssey, 16–19 September 2001, Calgary, Canada, pp 339–346

Belem T, Homand-Etienne F, Souley M (1997) Fractal analysis of shear joint roughness. Int J Rock Mech Min Sci 34:(3–4), Paper No. 130

Belem T, Homand-Etienne F, Souley M (2000) Quantitative parameters for rock joint surface roughness. Rock Mech Rock Eng 33(4):217–242

Benjelloun ZH, Boulon M, Billaux D (1990) Experimental and numerical investigation on rock joints.In: Barton N, Stephansson O (eds) Rock joints. Balkema, Rotterdam, pp 171–178

Cundall PA (1980) UDEC-a generalized distinct element program for modelling jointed rock. Report PCAR-1–80, Peter Cundall Associates, European Research Office, US Army Corps of Engineers

Cundall PA, Marti J (1979) Some new developments in discrete numerical methods for dynamic modelling of jointed rock masses. Proc Conf Rapid Excavation Tunnelling 2:1464–1466

Desai CS, Fishman KL (1991) Plasticity-based constitutive model with associated testing for joints. Int J Rock Mech Min Sci Geomech Abstr 28(1):15–26

Dieterich JH, Kilgore BD (1996) Imaging surface contacts: power law contact distributions and contact stresses in quartz, calcite, glass and acrylic plastic. Tectonophysics 256:219–239

El Soudani SM (1978) Profilometric analysis of fractures. Metallography 11:247–336

Fardin N (2007) Influence of structural non-stationarity of surface roughness on morphological characterization and mechanical deformation of rock joints. Rock Mech Rock Eng. doi:10.1007/s00603-007-0144-9

Fardin N, Stephansson O, Jing L (2001) The scale dependence of rock joint surface roughness. Int J Rock Mech Min Sci 38:659–669

Feng Q, Fardin N, Jing L, Stephansson O (2003) A new method for in-situ non-contact roughness measurement of large rock fracture surfaces. Rock Mech Rock Eng 36(1):3–25

Gentier S, Lamontagne E, Archambault G, Riss J (1997) Anisotropy of flow in a fracture undergoing shear and its relationship to the direction of shearing and injection pressure. Int J Rock Mech Min Sci 34(3–4):412

Gentier S, Riss J, Archambault G, Flamand R, Hopkins DL (2000) Influence of fracture geometry on sheared behavior. Int J Rock Mech Min Sci 37:161–174

Glaeser WA (1971) Friction and wear. IEEE Transactions on Parts, Hybrids, and Packaging, PHP-7(2):99–105

Goodman RE (1976) Methods of geological engineering in discontinuous rocks. West Publishing Company, San Francisco

Grasselli G, Wirth J, Egger P (2002) Quantitative three-dimensional description of a rough surface and parameter evolution with shearing. Int J Rock Mech Min Sci 39(6):789–800

Haberfield CM, Johnston IW (1994) A mechanistically-based model for rough rock joint. Int J Rock Mech Min Sci Geomech Abstr 31(4):279–292

Homand F, Belem T, Souley M (2001) Friction and degradation of rock joint surfaces under shear loads. Int J Numer Anal Meth Geomech 25:973–999

Homand F, Lefêvre F, Belem T, Souley M (1999) Rock joints behaviour under cyclic direct shear tests. In: Amadei B, Kranz RL, Scott GA, Smealie PA (eds) Rock Mechanics for Industry, vol 2. Balkema, Rotterdam, pp 399–406

Huang X, Haimson BC, Plesha ME, Qiu X (1993) An investigation of the mechanics of rock joints-part I. Laboratory investigation. Int J Rock Mech Min Sci Geomech Abstr 30:257–69

Hutson RW, Dowding CH (1990) Joint asperity degradation during cyclic shear. Int J Rock Mech Min Sci Geomech Abstr 27(2):109–119

Jiang Y, Li B, Tanabashi Y (2006) Estimating the relation between surface roughness and mechanical properties of rock joints. Int J Rock Mech Min Sci 43:837–846

Jing L (2003) A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering. Int J Rock Mech Min Sci 40:283–353

Jing L, Stephansson O, Nordlund E (1993) Study of rock joints under cyclic loading conditions. Rock Mech Rock Eng 26:215–232

Kimura T, Esaki T (1995) A new model for the shear strength of rock joints with irregular surfaces. In: Rossmanith H-P (ed) Mechanics of jointed and faulted rock. Balkema, Rotterdam, pp 133–138

Kragelskii IV (1965) Friction and wear. L Ronson, Trans Butterworth, London, pp 117–118

Kulatilake PHSW, Balasingam P, Park J, Morgan R (2006) Natural joint roughness quantification through fractal techniques. Geoteh Geol Eng 24:1181–1202

Kwasniewski MA, Wang JA (1997) Surface roughness evolution and mechanical behaviour of rock joints under shear. Int J Rock Mech Min Sci 34(3–4):709 (Paper No. 157)

Ladanyi B, Archambault G (1970) Simulation of the shear behaviour of a jointed rock mass. In: 11th U.S. symposium on rock mechanics, Berkeley, pp 105–125

Lanaro F (2000) A random field model for surface roughness and aperture of rock fractures. Int J Rock Mech Min Sci 37:1195–210

Lee HS, Park YJ, Cho TF, You KH (2001) Influence of asperity degradation on the mechanical behavior of rough rock joints under cyclic shear loading. Int J Rock Mech Min Sci 38:967–980

Lee SD, Lee CI, Park Y (1997) Characterization of joint profiles and their roughness parameters. Int J Rock Mech Min Sci 34:(3–4) Paper No. 174

Lefêvre F (1999) Mechanical behaviour and discontinuities morphology during shearing (French). Ph.D. thesis, INPL, Nancy, 199p

Marache A, Riss J, Gentier S, Chilès JP (2002) Characterization and reconstruction of a rock fracture surface by geostatistics. Int J Num Anal Meth Geomech 26:873–896

Mroz Z, Giambanco G (1996) In interface model for analysis of deformation behaviour of discontinuities. Int J Numer Anal Methods Geomech 20(1):1–33

Nguyen TS, Selvadurai APS (1998) A model for coupled mechanical and hydraulic behaviour of a rock joint. Int J Numer Anal Meth Geomech 22:29–48

Plesha ME (1987) Constitutive models for rock discontinuities with dilatancy and surface degradation. Int J Numer Anal Meth Geomech 11:345–362

Queener CA, Smith TC, Mitchell WL (1965) Transient wear of machine parts. Wear 8:391–400

Rabinowicz E (1965) Friction and wear of materials. Wiley, New York, pp 125–166

Rasouli V, Harrison JP (2000) Scale effect, anisotropy and directionality of discontinuity surface roughness. In: Proc., EUROCK 2000 14. Nationales Symposium für Felsmechanik und Tunnelbau, Aachen, Germany, pp 751–756

Renard F, Voisin C, Marsan D, Schmittbuhl J (2006) High resolution 3D laser scanner measurements of a strike-slip fault quantify its morphological anisotropy at all scales: Geophys Res Lett 33:L04305. doi:10.1029/2005GL025038

Riss J, Gentier S, Archambault G, Flamand R (1997) Sheared rock joints: dependence of damage zones on morphological anisotropy. Int J Rock Mech Min Sci 34:537

Roko RO, Daemen JJK, Myers DE (1997) Variogram characterization of joint surface morphology and asperity deformation during shearing. Int J Rock Mech Min Sci 34(1):71–84

Sagy A, Brodsky EE, Axen GJ (2007) Evolution of fault-surface roughness with slip. Geology 35(3):283–286

Sharifzadeh M, Mitani Y, Esaki T (2006) Rock joint surfaces measurement and analysis of aperture distribution under different normal and shear loading using GIS. Rock Mech Rock Eng. doi:10.1007/s00603-006-0115-6

Son BK, Lee YK, Lee CI (2001) Elasto-plastic simulation of a direct shear test on rough rock joints. Int J Rock Mech Min Sci 41(3) Paper 2A 07, CD-ROM

Souley M, Homand F, Amadei B (1995) An extension of the Saeb and Amadei constitutive model for rock joints to include cyclic loading paths. Int J Rock Mech Min Sci Geomech Abstr 32(2):101–109

Tannant DD, Kaiser PK (1993) A shear-dependent fracture-zone transmissivity model. Can Geotech J 30(1):146–154

Teer DG, Arnell RD (1978) In: Halling J (ed) Wear principles of tribology. McMillian, London, pp 94–127

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16:303–307

Unal M, Unver B (2004) Characterization of rock joint surface degradation under shear loads. Int J Rock mech Min Sci 41:(3), Paper 1a 24, CD-ROM

Xie H, Wang JA (1999) Direct fractal measurement of fracture surfaces. Int J Solids Struct 36:3073–3084

Yang ZY, Chiang DY (2000) An experimental study on the progressive shear behavior of rock joints with tooth-shaped asperities. Int J Rock Mech Min Sci 37(8):1247–1259

Yang ZY, Di CC, Yen KC (2001) The effect of asperity order on the roughness of rock joints. Int J Rock Mech Min Sci 38:745–752

Yeo IW, De Freitas MH, Zimmerman RW (1998) Effect of shear displacement on the aperture and permeability of a rock fracture. Int J Rock Mech Min Sci 35(8):1051–1070

Zhou HW, Xie H (2004) Anisotropic characterization of rock fracture surfaces subjected to profile analysis. Phys Lett A 325:355–362

Zubelewicz A, O’Connor K, Dowding CH, Belytschko T, Plesha ME (1987) A constitutive model for cyclic behavior of dilatant rock joints. Proc Second Int Conference Constitutive Laws Eng Mater 2:1137–44

Author information

Authors and Affiliations

Corresponding author

Appendix 1: Estimating the proposed roughness parameters

Appendix 1: Estimating the proposed roughness parameters

The minimum requirement for estimating the proposed roughness parameters is the value of the Z2 parameter, which is given by:

where subscripts x and y denote the directions supporting the profile data acquisition; N = number of discrete measurements of height; Δx = sampling step; and z i = discrete height of the point on the profile.

The Z2 value can also be derived from the empirical relationship proposed by Tse and Cruden [58], as follows:

where JRC = joint roughness coefficient defined in [6].

The procedure to estimate proposed roughness parameters is as follows:

-

(a)

estimation of the roughness profile mean angles θ p(x) and θ p(y), starting from Z2(x) and Z2(y)

-

(b)

calculation of the pseudo-surfacial mean angle \(\theta_{p\_xy} (= [\theta_{p(x)} + \theta_{p(y)}]/2)\) and k a (Eq. 2)

-

(c)

estimation of the surface mean angle θs from the pseudo-surfacial mean angle \(\theta_{p\_xy}\)

-

(d)

calculation of R *s = cos−1(θs) before estimating R s from R *s

-

(e)

calculation of surface roughness coefficient R s

-

(f)

calculation of the degree of surface relative roughness, DRr = (R s−1)/R s

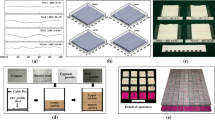

To obtain different empirical equations, the main morphological parameters (θ p(x), θ p(y), k a, θs, DRr) were calculated for the four different joint types: two man-made granite joints with a sanded surface (a 0 = 0.552 mm) and a hammered surface (a 0 = 1.742 mm), and two mortar joints with a corrugated surface (a 0 = 2.000 mm) and an irregular rough surface (a 0 = 8.103 mm). The man-made joints represented “pure” second-order roughness, while the mortar joints represented a combination of second-order and first-order roughness. The resultant equations are given as follows:

-

(a)

$$\left\{\begin{aligned}& \theta_{{p(x,y)}} = a_{0}^{3} {\left({46.5135{\left({\frac{{Z2_{{x,y}}}}{{a_{0}^{3}}} + 0.0145} \right)}^{{1.1389}}} \right)}\quad{\hbox{for}}\quad a_{0} < 2 \\& \\& \theta _{{p(x,y)}} = a_{0}^{3} {\left({42.9125{\left({\frac{{Z2_{{x,y}}}}{{a_{0}^{3}}}} \right)} + 0.0216} \right)}\quad{\hbox{for}}\quad a_{0} \geq 2 \\ \end{aligned} \right.$$(54)

-

(b)

$$\theta_{p\_xy} = \frac{\theta_{p(x)} + \theta _{p(y)}}{2}$$(55)

-

(c)

$$\left\{\begin{aligned}& \theta_{s} = a_{0}^{3} {\left({1.5171{\left({\frac{{\theta_{{p\_xy}}}}{{a_{0}^{3}}}} \right)} - 0.0688} \right)}\quad{\hbox{for}}\quad a_{0} < 2 \\& \\& \theta_{s} = a_{0} ^{3} {\left({1.7081{\left({\frac{{\theta_{{p\_xy}}}}{{a_{0}^{3}}}} \right)}^{{1.089}}} \right)}\quad{\hbox{for}}\quad a_{0} \geq 2 \\ \end{aligned} \right.$$(56)

-

(d)

(According to Riss et al. [50])

$$R^{{{*}}}_{\rm s} = \frac{1}{{\cos (\theta_{\rm s})}}$$(57) -

(e)

$$\left\{\begin{aligned}& R_{\rm s} = a_{0} \times 1.0081{\left({\frac{{R^{*}_{\rm s}}}{{a_{0}}}} \right)}^{{0.9899}}\quad {\hbox{for}}\quad a_{0} < 2 \\& \\& R_{\rm s} = a_{0} \times 0.9971{\left({\frac{{R^{*}_{\rm s}}}{{a_{0}}}} \right)}^{{0.9878}}\quad {\hbox{for}}\quad a_{0} \geq 2 \\ \end{aligned} \right.$$(58)

-

(f)

$${\rm DR}_{\rm r} = {\left({1 - \frac{1}{{R_{\rm s}}}} \right)}$$(59)

Rights and permissions

About this article

Cite this article

Belem, T., Souley, M. & Homand, F. Modeling surface roughness degradation of rock joint wall during monotonic and cyclic shearing. Acta Geotech. 2, 227–248 (2007). https://doi.org/10.1007/s11440-007-0039-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-007-0039-7