Abstract

This study is to investigate the change in resultant force, cutting coefficient and normalized resultant force of the TBM (tunnel boring machine) disc cutter when using different cutting conditions and different linear cutting machines. Full-scale linear cutting tests on three rocks of different compressive strengths were conducted. The experimental results, combined with other previously published data, were compared to the prediction results of the semi-theoretical CSM (Colorado School of Mines) prediction model. The influences of rock compressive strength, disc cutter diameter and machine frame stiffness on the comparison results were analysed. From the general view, experimental resultant forces tend to be underestimated while experimental cutting coefficients and normalized resultant forces both tend to be overestimated when using the semi-theoretical CSM prediction model, and the underestimation or overestimation degrees are different when the above three influencing factors are different. The reason responsible for these phenomena can be mainly attributed to the lower actual cutter penetration depth compared to the pre-set one during the rock–machine interaction process. The results of this study can offer more accurate understanding of the full-scale linear cutting tests using different cutting conditions and different linear cutting machines, and thus it can contribute to the more reliable and accurate prediction on disc cutter cutting forces.

Similar content being viewed by others

Abbreviations

- β :

-

Acting angle of the disc cutter resultant force referred to the normal direction

- θ :

-

Angle of the studied point referred to the normal direction, 0 < θ < φ

- φ :

-

Contact angle between rock surface and disc cutter

- σ c :

-

Rock uniaxial compressive strength

- σ t :

-

Rock Brazilian tensile strength

- ψ :

-

Contact pressure distribution constant, typically − 0.2 to 0.2

- C :

-

Constant in the semi-theoretical CSM prediction model, usually taken as 2.12

- CC:

-

Disc cutter cutting coefficient obtained in the full-scale linear cutting test

- CCRost :

-

Disc cutter cutting coefficient predicted by the semi-theoretical CSM prediction model

- D :

-

Disc cutter diameter

- FT:

-

Disc cutter resultant force obtained in the full-scale linear cutting test

- FN:

-

Disc cutter normal force obtained in the full-scale linear cutting test

- FR:

-

Disc cutter rolling force obtained in the full-scale linear cutting test

- FTRost :

-

Disc cutter resultant force predicted by the semi-theoretical CSM prediction model

- FNRost :

-

Disc cutter normal force predicted by the semi-theoretical CSM prediction model

- FRRost :

-

Disc cutter rolling force predicted by the semi-theoretical CSM prediction model

- FTRost, M :

-

Disc cutter resultant force predicted by the modified semi-theoretical CSM prediction model

- FNRost, M :

-

Disc cutter normal force predicted by the modified semi-theoretical CSM prediction model

- FRRost, M :

-

Disc cutter rolling force predicted by the modified semi-theoretical CSM prediction model

- KC:

-

Modification factor for disc cutter cutting coefficient

- KT:

-

Modification factor for disc cutter resultant force

- NRF:

-

Normalized resultant force of the disc cutter

- NRFavg :

-

Averaged normalized resultant force obtained in the full-scale linear cutting test

- NRFRost :

-

Normalized resultant force assumed in the semi-theoretical CSM prediction model, set as 0.5000

- p :

-

Cutter penetration depth

- P 0 :

-

Base contact pressure immediately underneath the disc cutter

- P θ :

-

Contact pressure distribution function within the rock-cutter contact area

- R :

-

Disc cutter radius

- s :

-

Disc cutter spacing

- T :

-

Disc cutter tip width

- v 0 :

-

Cutting velocity in the full-scale linear cutting test (20 mm/s in this study)

- BJUT-LCM:

-

Linear cutting machine in Beijing University of Technology

- CCS:

-

Constant cross-section

- CSM-LCM:

-

Linear cutting machine in Colorado School of Mines

- ILCM:

-

Intermediate linear cutting machine in Politecnico di Torino

- ITU-LCM:

-

Linear cutting machine in Istanbul Technical University

- KICT-LCM:

-

Linear cutting machine in Korean Institute of Construction Technology

- LCM:

-

Linear cutting machine

- TBM:

-

Tunnel boring machine

References

Balci C (2009) Correlation of rock cutting tests with field performance of a TBM in a highly fractured rock formation: a case study in Kozyatagi-Kadikoy metro tunnel, Turkey. Tunn Undergr Space Technol 24:423–435. https://doi.org/10.1016/j.tust.2008.12.001

Balci C, Tumac D (2012) Investigation into the effects of different rocks on rock cuttability by a V-type disc cutter. Tunn Undergr Space Technol 30:183–193. https://doi.org/10.1016/j.tust.2012.02.018

Bilgin N, Algan M (2012) The performance of a TBM in a squeezing ground at Uluabat, Turkey. Tunn Undergr Space Technol 32:58–65. https://doi.org/10.1016/j.tust.2012.05.004

Cardu M, Iabichino G, Oreste P, Rispoli A (2017) Experimental and analytical studies of the parameters influencing the action of TBM disc tools in tunnelling. Acta Geotech 12(2):293–304. https://doi.org/10.1007/s11440-016-0453-9

Chen LH, Labuz JF (2006) Indentation of rock by wedge-shaped tools. Int J Rock Mech Min Sci 43:1023–1033. https://doi.org/10.1016/j.ijrmms.2006.03.005

Cho JW, Jeon S, Jeong HY, Chang SH (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54. https://doi.org/10.1016/j.tust.2012.08.006

Choi SW, Chang SH, Park YT, Lee GP, Bae GJ (2014) Comparative analysis of cutter acting forces and axial stresses of single and double disc cutters by linear cutting tests. J Korean Tunn Undergr Space Assoc 16(2):181–191. https://doi.org/10.9711/KTAJ.2014.16.2.181(in Korean)

Copur H, Aydin H, Bilgin N, Dincer T (2014) Predicting performance of EPB TBMs by using a stochastic model implemented into a deterministic model. Tunn Undergr Space Technol 42:1–14. https://doi.org/10.1016/j.tust.2014.01.006

Entacher M, Lorenz S, Galler R (2014) Tunnel boring machine performance prediction with scaled rock cutting tests. Int J Rock Mech Min Sci 70:450–459. https://doi.org/10.1016/j.ijrmms.2014.04.021

Farmer I, Garrity P, Glossop N (1987) Operational characteristics of full face tunnel boring machines. In: Rapid excavation and tunnelling conference, pp 188–201

Frenzel C, Käsling H, Thuro K (2008) Factors influencing disc cutter wear. Geomech Tunn 1:55–60

Frenzel C (2011) Disc cutter wear phenomenology and their implications on disc cutter consumption for TBM. In: the 45th US rock mechanics/geomechanics symposium held in San Francisco, CA, June 26–29

Frenzel C, Galler R, Käsling H, Villeneuve MC (2012) Penetration tests for TBMs and their practical application. Geomech Tunn 5:557–566. https://doi.org/10.1002/geot.201200042

Gertsch R (1993) Tunnel boring machine disk cutter vibrations. MS thesis, Colorado School of Mines, Golden, CO

Gertsc R (2000) Rock toughness and disc cutting. PhD thesis, University of Missouri, Rola, MO

Gertsch R, Ozdemir L (1992) Performance prediction of mechanical excavators from linear cutter tests on Yucca Mountain welded tuffs: Yucca Mountain Site Characterization Project. Office of Scientific & Technical Information Technical Reports. https://doi.org/10.2172/138470

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado Red Granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44:238–246. https://doi.org/10.1016/j.ijrmms.2006.07.007

Gong QM, Zhao J, Jiao YY (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 20:183–191. https://doi.org/10.1016/j.tust.2004.08.006

Gong QM, Jiao YY, Zhao J (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21:46–55. https://doi.org/10.1016/j.tust.2005.06.004

Gong QM, Zhao J, Hefny AM (2006) Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization. Tunn Undergr Space Technol 21:263. https://doi.org/10.1016/j.tust.2005.12.124

Gong QM, He GW, Zhao XB, Ma HS, Li XZ (2015) Influence of different cutter spacings on rock fragmentation efficiency of Beishan granite by TBM. Chin J Geotech Eng 37(1):54–60. https://doi.org/10.11779/CJGE201501005(in Chinese)

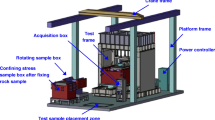

Gong QM, Du XL, Li Z, Wang QX (2016) Development of a mechanical rock breakage experimental platform. Tunn Undergr Space Technol 57:129–136. https://doi.org/10.1016/j.tust.2016.02.019

Gong QM, Dong GL, Yin LJ, Ma S, Lu JW (2016) Comparison study on the rock linear and rotating cutting tests by TBM cutter. Constr Technol 53(1):62–68 (in Chinese)

Huang H, Damjanac B, Detournay E (1998) Normal wedge indentation in rocks with lateral confinement. Rock Mech Rock Eng 31(2):81–94

Innaurato N, Oggeri C, Oreste PP, Vinai R (2007) Experimental and numerical studies on rock breaking with TBM tools under high stress confinement. Rock Mech Rock Eng 40(5):429–451. https://doi.org/10.1007/s00603-006-0109-4

Laughton C (1998) Evaluation and prediction of tunnel boring machine performance in variable rock masses. PhD thesis. The Graduate School of the University of Texas at Austin, Austin

Li XF, Li HB, Liu YQ, Zhou QC, Xia X (2016) Numerical simulation of rock fragmentation mechanisms subject to wedge penetration for TBMs. Tunn Undergr Space Technol 53:96–108. https://doi.org/10.1016/j.tust.2015.12.010

Lislerud A (1997) Principles of mechanical excavation. Posiva report 97-12

Liu HY, Kou SQ, Lindqvist P, Tang CA (2002) Numerical simulation of the rock fragmentation process induced by indenters. Int J Rock Mech Min Sci 39:491–505. https://doi.org/10.1016/S1365-1609(02)00043-6

Liu J, Cao P, Han DY (2015) Sequential indentation tests to investigate the influence of confining stress on rock breakage by tunnel boring machine cutter in a biaxial state. Rock Mech Rock Eng 49:1479–1495. https://doi.org/10.1007/s00603-015-0843-6

Liu QS, Pan YC, Liu JP, Kong XX, Shi K (2016) Comparison and discussion on fragmentation behavior of soft rock in multi-indentation tests by a single TBM disc cutter. Tunn Undergr Space Technol 57:151–161. https://doi.org/10.1016/j.tust.2016.02.021

Liu QS, Pan YC, Kong XX, Liu JP, Shi K, Cui XZ, Huang SB (2016) Experimental investigation on mudstone fragmentation characteristics in indentation process by TBM disc cutter. Rock Soil Mech 37(S1):166–174 (in Chinese)

Liu QS, Pan YC, Liu JP, Kong XX, Shi K, Liu Q (2016) Analysis on fragmentation behavior of rocks in indentation tests by disc cutter. Chin J Rock Mech Eng 35(S2):3516–3525 (in Chinese)

Ma HS, Yin LJ, Ji HG (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int J Rock Mech Min Sci 48:1021–1033. https://doi.org/10.1016/j.ijrmms.2011.05.002

Ma HS, Yin LJ, Gong QM, Wang J (2015) TBM tunneling in mixed-face ground: problems and solutions. Int J Min Sci Technol 25:641–647. https://doi.org/10.1016/j.ijmst.2015.05.019

Moon T, Oh J (2012) A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech Rock Eng 45:837–849. https://doi.org/10.1007/s00603-011-0180-3

Nelson PP, Jalil YA, Laughton C (1992) Analysis of performance measures of tunnel boring machines. In: Eurock’92, London, pp 408–413

Pan YC, Liu QS, Liu JP, Peng XX, Kong XX (2018) Full-scale linear cutting tests in Chongqing Sandstone to study the influence of confining stress on rock cutting forces by TBM disc cutter. Rock Mech Rock Eng 51(6):1697–1713. https://doi.org/10.1007/s00603-018-1412-6

Pan YC, Liu QS, Peng XX, Kong XX, Liu JP, Zhang XB (2018) Full-scale rotary cutting test to study the influence of disc cutter installment radius on rock cutting forces. Rock Mech Rock Eng 51(7):2223–2236. https://doi.org/10.1007/s00603-018-1460-y

Pan YC, Liu QS, Liu JP, Huang X, Liu Q, Peng XX (2018) Comparison between experimental and semi-theoretical disc cutter cutting forces: implications for frame stiffness of the linear cutting machine. Arab J Geosci 11:226. https://doi.org/10.1007/s12517-018-3593-4

Pan YC, Liu QS, Liu JP, Liu Q, Kong XX (2018) Full-scale linear cutting tests in Chongqing Sandstone to study the influence of confining stress on rock cutting efficiency by TBM disc cutter. Tunn Undergr Space Technol 80:197–210. https://doi.org/10.1016/j.tust.2018.06.013

Pan YC, Liu QS, Kong XX, Liu JP, Peng XX, Liu Q (2018) Full-scale linear cutting test in Chongqing Sandstone and the comparison with field TBM excavation performance. Acta Geotech. https://doi.org/10.1007/s11440-018-0702-1(accepted)

Pang SS, Goldsmith W (1990) Investigation of crack formation during loading of brittle rock. Rock Mech Rock Eng 23:53–63. https://doi.org/10.1007/BF01020422

Rostami J (1991) Design optimization, performance predictions, and economic analysis of TBM application in the proposed Yucca mountain nuclear waste repository. MS thesis 4139, Colorado School of Mines, Golden, Colorado, USA

Rostami J, Ozdemir L (1993) A new model for performance prediction of hard rock TBMs. In: Proceedings of rapid excavation and tunneling conference, USA, pp 794–809

Rostami J, Ozdemir L, Nilsen B (1996) Comparison between CSM and NTH hard rock TBM performance prediction models. In: Proceedings of annual technical meeting of the institute of shaft drilling and technology (ISDT), Las Vegas, NV

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure. PhD thesis, Colorado School of Mines, Golden, Colorado

Rostami J (2013) Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters. Int J Rock Mech Min Sci 57:172–186. https://doi.org/10.1016/j.ijrmms.2012.07.031

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12:361–366. https://doi.org/10.1016/0148-9062(75)90547-1

Tan XC, Kou SQ, Lindqvist PA (1998) Application of the DDM and fracture mechanics model on the simulation of rock breakage by mechanical tools. Eng Geol 49:277–284. https://doi.org/10.1016/S0013-7952(97)00059-8

Tumac D, Balci C (2015) Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations. Tunn Undergr Space Technol 45:84–98. https://doi.org/10.1016/j.tust.2014.09.009

Xia YM, Guo B, Tan Q, Zhang XH, Lan H, Ji ZY (2018) Comparisons between experimental and semi-theoretical cutting forces of CCS disc cutters. Rock Mech Rock Eng 51(5):1583–1597. https://doi.org/10.1007/s00603-018-1400-x

Yasar S, Yilmaz AO (2017) A novel mobile testing equipment for rock cuttability assessment: vertical Rock Cutting Rig (VRCR). Rock Mech Rock Eng 50(4):1–13. https://doi.org/10.1007/s00603-016-1149-z

Yasar S, Yilmaz AO (2017) Rock cutting tests with a simple-shaped chisel pick to provide some useful data. Rock Mech Rock Eng 50(12):3261–3269. https://doi.org/10.1007/s00603-017-1303-2

Yasar S, Yilmaz AO (2018) Drag pick cutting tests: a comparison between experimental and theoretical results. J Rock Mech Geotech Eng 10(05):93–106. https://doi.org/10.1016/j.jrmge.2018.02.007

Yin LJ, Gong QM, Ma HS, Zhao J, Zhao XB (2014) Use of indentation tests to study the influence of confining stress on rock fragmentation by a TBM cutter. Int J Rock Mech Min Sci 72:261–276. https://doi.org/10.1016/j.ijrmms.2014.07.022

Zhai SF, Zhou XP, Bi J, Xiao N (2016) The effects of joints on rock fragmentation by TBM cutters using General Particle Dynamics. Tunn Undergr Spce Technol 57:162–172. https://doi.org/10.1016/j.tust.2016.01.035

Zhai SF, Zhou XP, Bi J, Qian QH (2017) Validation of GPD to model rock fragmentation by TBM cutters. Int J Geomech 17(6):06016036. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000829

Zhang H, Huang GY, Song HP, Kang YL (2012) Experimental investigation of deformation and failure mechanisms in rock under indentation by digital image correlation. Eng Fract Mech 96:667–675. https://doi.org/10.1016/j.engfracmech.2012.09.012

Zhao J, Gong QM, Eisensten Z (2007) Tunnelling through a frequently changing and mixed ground: a case history in Singapore. Tunn Undergr Space Technol 22:388–400. https://doi.org/10.1016/j.tust.2006.10.002

Zhou XP, Zhai SF (2018) Estimation of the cutterhead torque for earth pressure balance TBM under mixed-face conditions. Tunn Undergr Space Technol 74:217–229. https://doi.org/10.1016/j.tust.2018.01.025

Acknowledgements

This work was financially supported by National Natural Science Foundation of China under Grant Nos. 41807250 and 41602326, National Key Basic Research Program of China under Grant Nos. 2015CB058102 and 2014CB046903, and China Postdoctoral Science Foundation Program under Grant Nos. 2019T120686 and 2017M622515. The authors are grateful for their continuous support, and also very much grateful to the authors’ colleagues for their valuable help in organizing this article. Prof. Qiuming Gong’s postgraduates at Beijing University of Technology are sincerely acknowledged for helping the authors prepare the rock samples and conduct the full-scale linear cutting tests. The anonymous reviewers are also deeply acknowledged for reviewing this article and giving their valuable comments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Table 6.

Rights and permissions

About this article

Cite this article

Pan, Y., Liu, Q., Liu, Q. et al. Full-scale linear cutting tests to check and modify a widely used semi-theoretical model for disc cutter cutting force prediction. Acta Geotech. 15, 1481–1500 (2020). https://doi.org/10.1007/s11440-019-00852-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-019-00852-4