Abstract

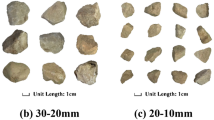

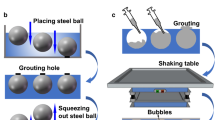

This paper presents a fundamental study on the effect of the relative humidity on the rockfill crushing strength. This aspect plays an important role in the mechanical behaviour of rockfill, and it is known that certain characteristics of the granular materials, such as compressibility and shear strength, depend on the confining stress, which is a function of the particles crushing. An increased interest has been observed regarding the effect of the relative humidity in the mechanical behaviour of rockfill. Unfortunately, limited research has been conducted until now regarding the study of individual particle crushing. Therefore, this paper thoroughly investigated particle crushing, by performing single-particle crushing tests on rockfill particles divided into four size ranges, under different relative humidity conditions. The experimental results reveal a considerable influence of the relative humidity in the studied rockfill particles, whose strength of the particles with the greatest dimensions in saturated conditions was reduced by half. Consistent macro-mechanical evidence demonstrates that particle’s size and relative humidity conditions depict the most important factors that influence particle crushing strength.

Similar content being viewed by others

References

Alonso EE, Tapias MA (2019) Suction and time effects in rockfill deformation. Int J Numer Anal Methods Geomech 43(5):1032–1050

Altuhafi FN, Coop MR (2011) Changes to particle characteristics associated with the compression of sands. Geotechnique 61(6):459–471

Atkinson BK (1984) Subcritical crack growth in geological materials. J Geophys Res Solid Earth 89(B6):4077–4114

Atkinson B, Meredith P (1987) The theory of subcritical crack growth with application to minerals and rocks. In: Atkinson BK (ed) Fracture mechanics of rock, pp 111–166

B Standard BS EN ISO 483:2005 (2005) Plastics. Small enclosures for conditioning and testing using aqueous solutions to maintain the humidity at constant value. International Organization for Standardization, vol 483, Geneva, Switzerland, p 12

Baud P, Zhu W, Wong TF (2000) Failure mode and weakening effect of water on sandstone. J Geophys Res 105(B7):16371

Cai C et al (2019) Laboratory investigation on strengthening behavior of frozen China standard sand. Acta Geotech 14(1):179–192

Ciantia MO, Arroyo M, O’Sullivan C, Gens A (2019) Micromechanical inspection of incremental behaviour of crushable soils. Acta Geotech 14(5):1337–1356

Clements RP (1981) The deformation of rockfill: inter-particle behaviour, bulk properties and behaviour in dams. University of London

Deng B, Jiang D, Gong J (2018) Is a three-parameter Weibull function really necessary for the characterization of the statistical variation of the strength of brittle ceramics? J Eur Ceram Soc 38(4):2234–2242

Einav I (2007) Breakage mechanics—part II: modelling granular materials. J Mech Phys Solids 55(6):1298–1320

Einav I (2007) Breakage mechanics—part I: theory. J Mech Phys Solids 55(6):1274–1297

Fok SL, Mitchell BC, Smart J, Marsden BJ (2001) A numerical study on the application of the Weibull theory to brittle materials. Eng Fract Mech 68(10):1171–1179

Frieman SW (1984) Effects of chemical environments on slow crack growth in glasses and ceramics. J Geophys Res 89(B6):4072–4076

Frossard E, Hu W, Dano C, Hicher PY (2012) Rockfill shear strength evaluation: a rational method based on size effects. Geotechnique 62(5):415–427

Fumagalli E (1969) Tests on cohesionless materials for rockfill dams. J Soil Mech Found Div 95(1):313–332

Griffith (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond. 221

Hu W, Dano C, Hicher P, Le Touzo J, Derkx F, Merliot E (2011) Effect of sample size on the behavior of granular materials 34(3)

Huang J, Xu S, Hu S (2014) Influence of particle breakage on the dynamic compression responses of brittle granular materials. Mech Mater 68:15–28

Irwin GR (1958) Handbuch der Physik VI: 551–590

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics. Wiley

Johnson KL (1985) Contact mechanics. Cambridge University, Cambridge

Lee K, Farhoomand I (1967) Compressibility and crushing of granular soil in anisotropic triaxial compression. Can Geotech J IV(1)

Lim WL, McDowell GR, Collop AC (2004) The application of Weibull statistics to the strength of railway ballast. Granul Matter 6(4):229–237

Lu C, Danzer R, Fischer FD (2002) Influence of threshold stress on the estimation of the Weibull statistics. J Am Ceram Soc 85(6):1640–1642

Manso J, Marcelino J, Caldeira L (2018) Crushing and oedometer compression of rockfill using DEM. Comput Geotech

Marachi ND, Chan CK, Seed HB, Duncan JM (1969) Strength and deformation characteristics of rockfill materials

Marsal RJ (1967) Large-scale testing of rockfill materials. J Soil Mech Found Div ASCE 93(2):27–43

Marsal RJ (1973) Mechanical properties of rockfill. In: Embankment-dam engineering: casagrande volume. In: Hirschfeld RC, Poulos SJ (eds) Wiley, pp 109–200

Marsal RJ, Alberro J, Auvinet G (1977) Behaviour of dams built in Mexico

McDowell GR (2001) Discussion: a probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 51(3):285–287

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40(5):133–141

McDowell G, Bolton MD (1998) On the micromechanics of crushable aggregates. Geotechnique 48(5):667–679

Nakata FL, Hyde M, Hyodo H (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49(5):567–583

Nara Y, Hiroyoshi N, Yoneda T, Kaneko K (2010) Effects of relative humidity and temperature on subcritical crack growth in igneous rock. Int J Rock Mech Min Sci 47(4):640–646

Nara Y, Morimoto K, Yoneda T, Hiroyoshi N, Kaneko K (2011) Effects of humidity and temperature on subcritical crack growth in sandstone. Int J Solids Struct 48(7–8):1130–1140

Naylor DJ, Maranha J, Maranha das Neves E, Veiga Pinto A (1997) A back-analysis of Beliche Dam. Geotechnique 47(2):221–233

Okada Y, Sassa K, Fukuoka H (2004) Excess pore pressure and grain crushing of sands by means of undrained and naturally drained ring-shear tests. Eng Geol 75(3–4):325–343

Oldecop LA, Alonso EE (2001) A model for rockfill compressibility. Géotechnique 51(2):127–139

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher PY (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225(8):2199–2216

Penman ADM, Charles J (1975) The quality and suitability of rockfill used in dam construction. Build Res Establ Watford Curr Pap CP 87/75 34654, p 14

Schulze HJ (1984) Physico-chemical elementary processes in flotation. Elsevier, Amsterdam, p 1984

Shen Z, Gao F, Wang Z, Jiang M (2019) Evolution of mesoscale bonded particle clusters in cemented granular material. Acta Geotech 14(6):1653–1667

Shen C, Liu S, Wang L, Wang Y (2019) Micromechanical modeling of particle breakage of granular materials in the framework of thermomechanics. Acta Geotech 14(4):939–954

Silvani C, Bonelli S, Philippe P, Desoyer T (2008) Buoyancy and local friction effects on rockfill settlements: a discrete modelling. Comput Math Appl 55(2):208–217

Smart J, Mitchell BC, Fok SL, Marsden BJ (2003) The effect of the threshold stress on the determination of the Weibull parameters in probabilistic failure analysis. Eng Fract Mech 70(18):2559–2567

Sowers GF, Williams RC, Wallace TS (1965) Compressibility of broken rock and settlement of rockfills. In: 6th ICSMFE, 2, Montreal, pp 561–565

Todisco MC, Wang W, Coop MR, Senetakis K (2017) Multiple contact compression tests on sand particles. Soils Found 57(1):126–140

Veiga Pinto A (1983) Previsão do comportamento estrutural de barragens de enrocamento

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Wiederhorn SM, Fuller ER, Thomson R (1980) Micromechanisms of crack growth in ceramics and glasses in corrosive environments. Met Sci 14(8–9):450–458

Xu L, Shen Z, Yang F, Gu X, Engineering H, Safety E (2012) Stress and deformation analysis for the concrete face rockfill dam of wuyue pumped storage power station, pp 986–995

Zeghal M (2009) The impact of grain crushing on road performance. Geotech Geol Eng 27(4):549–558

Zhang J, Wong TF, Davis DM (1990) Micromechanics of pressure-induced grain crushing in porous rocks. J Geophys Res 95(B1):341

Zhou C, Xu C, Karakus M, Shen J (2019) A particle mechanics approach for the dynamic strength model of the jointed rock mass considering the joint orientation. Int J Numer Anal Methods Geomech 43(18):2797–2815

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Manso, J., Marcelino, J. & Caldeira, L. Single-particle crushing strength under different relative humidity conditions. Acta Geotech. 16, 749–761 (2021). https://doi.org/10.1007/s11440-020-01065-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01065-w