Abstract

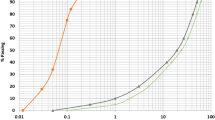

Dredging activities generate a huge amount of dredged clay slurry, and the treatment of it has been a challenge. Carbide sludge (CS)-activated ground-granulated blastfurnace slag (GGBS) can effectively stabilize clay slurry. However, in previous studies, the mechanical performance of CS–GGBS-treated slurry was only investigated through unconfined compressive strength (UCS) test, not triaxial shear strength test. Hence, in this study, the consolidated undrained (CU) triaxial test was conducted to investigate the triaxial strength behavior of CS–GGBS-treated slurry with 100% water content. The binder content was 60 kg/m3, and three CS:GGBS ratios of 1:9, 2:8, and 3:7 were used. For each treated slurry, six different pre-shear consolidation pressures ranging from 30 to 300 kPa were used. Results reveal that CS–GGBS-treated slurry has a bilinear failure envelop. When the pre-shear consolidation pressure is smaller than the yield stress, treated slurry has an effective cohesion of ~ 0.5UCS with an effective friction angle close to zero. However, when the pre-shear consolidation pressure exceeds the yield stress, the treated slurry only has a low effective cohesion of 0.13–0.26UCS, but a high effective friction angle of 31°-38°, higher than that of the untreated clay, i.e., 26°. This CU behavior of treated slurry can be explained by the soil-cementation structure upon shearing. When the pre-shear consolidation pressure is lower than the yield stress, the soil-cementation structure is nearly intact, which dominates the strength of treated slurry; however, when under high consolidation pressure, most cementation bonds break, and hence, the shear strength is attributed to the friction among soil particles and cohesion provided by residual cementation bonds. The influence of consolidation pressure on the treated slurry is further validated by isotropic consolidation results.

Similar content being viewed by others

References

Ajorloo A, Mroueh H, Lancelot L (2012) Experimental investigation of cement treated sand behavior under triaxial test. Geotech Geol Eng 30(1):129–143

ASTM (2013) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken

ASTM (2020) Standard test method for consolidated undrained triaxial compression test for cohesive soil. ASTM International, West Conshohocken

Benzerzour M, Amar M, Abriak N-E (2017) New experimental approach of the reuse of dredged sediments in a cement matrix by physical and heat treatment. Constr Build Mater 140:432–444

Bhattacharja S, Bhatty JI, Todres HA (2003) Stabilization of clay soils by Portland cement or lime–a critical review of literature. PCA R&D Serial 60(1):124–133

Bian X, Cao Y, Wang Z, Ding G, Lei G (2017) Effect of super-absorbent polymer on the undrained shear behavior of cemented dredged clay with high water content. J Mater Civ Eng 29(7):04017023

Bo M, Choa V, Hong K (2003) Material characterization of Singapore Marine Clayat Changi. Q J Eng GeolHydrogeol 36(4):305–319

Cabeza LF, Barreneche C, Miró L, Morera JM, Bartolí E, Fernández AI (2013) Low carbon and low embodied energy materials in buildings: a review. Renew Sustain Energy Rev 23:536–542

Cardoso FA, Fernandes HC, Pileggi RG, Cincotto MA, John VM (2009) Carbide lime and industrial hydrated lime characterization. Powder Technol 195(2):143–149

Chin K G (2006) Constitutive behaviour of cement treated marine clay. PhD Thesis. National University of Singapore, Singapore.

Chiu C, Zhu W, Zhang C (2009) Yielding and shear behaviour of cement-treated dredged materials. Eng Geol 103(1–2):1–12

Crossin E (2015) The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J Clean Prod 95:101–108

Dai F, Lee C, Wang S, Feng Y (1999) Stress–strain behaviour of a loosely compacted volcanic-derived soil and its significance to rainfall-induced fill slope failures. Eng Geol 53(3–4):359–370

He J, Chu J, Tan SK, Vu TT, Lam KP (2017) Sedimentation behavior of flocculant-treated soil slurry. Mar Georesour Geotechnol 35(5):593–602

He Z, Zhu X, Wang J, Mu M, Wang Y (2019) Comparison of CO2 emissions from OPC and recycled cement production. Constr Build Mater 211:965–973

Head KH (1998) Manual of soil laboratory testing. Wiley, London

Holtz R D, Kovacs W D, Sheahan T C (1981) An introduction to geotechnical engineering. Prentice-Hall, Englewood Cliffs.

Hong Z, Tateishi Y, Han J (2006) Experimental study of macro-and microbehavior of natural diatomite. J Geotechn Geoenviron Eng 132(5):603–610

Hong Y, Wang L, Ng CW, Yang B (2017) Effect of initial pore pressure on undrained shear behaviour of fine-grained gassy soil. Can Geotech J 54(11):1592–1600

Horpibulsuk S, Miura N, Bergado D (2004) Undrained shear behavior of cement admixed clay at high water content. J Geotechn Geoenviron Eng 130(10):1096–1105

Horpibulsuk S, Liu MD, Liyanapathirana DS, Suebsuk J (2010) Behaviour of cemented clay simulated via the theoretical framework of the structured cam clay model. Comput Geotech 37(1–2):1–9

Indraratna A, Balasubramanian A, Khan M (1995) Effect of fly ash with lime and cement on the behavior of a soft clay. Q J Eng GeolHydrogeol 28(2):131–142

Jaditager M, Sivakugan N (2017) Influence of fly ash–based geopolymer binder on the sedimentation behavior of dredged mud. J Waterw Port Coast Ocean Eng 143(5):04017012

James R, Kamruzzaman A, Haque A, Wilkinson A (2008) Behaviour of lime–slag-treated clay. Proc Instit Civil Eng Ground Improvement 161(4):207–216

Jongpradist P, Jumlongrach N, Youwai S, Chucheepsakul S (2010) Influence of fly ash on unconfined compressive strength of cement-admixed clay at high water content. J Mater Civ Eng 22(1):49–58

Kamruzzaman A, Chew S, Lee F (2009) Structuration and destructuration behavior of cement-treated Singapore marine clay. J Geotechn Geoenviron Eng 135(4):573–589

Kasama K, Zen K, Iwataki K (2006) Undrained shear strength of cement-treated soils. Soils Found 46(2):221–232

Kim B, Prezzi M (2008) Evaluation of the mechanical properties of class-F fly ash. Waste Manage 28(3):649–659

Kitazume M, Satoh T (2005) Quality control in central Japan international airport construction. Proc Instit Civil Eng Ground Improvement 9(2):59–66

Kou H, Jing H, Wu C, Ni P, Wang Y, Horpibulsuk S (2021) Microstructural and mechanical properties of marine clay cemented with industrial waste residue-based binder (IWRB). Acta Geotech, pp 1–19.

Lang L, Chen B, Li N (2021) Utilization of lime/carbide slag-activated ground granulated blast-furnace slag for dredged sludge stabilization. Mar Georesour Geotechnol 39(6):659–669

Li W, Yi Y (2020) Use of carbide slag from acetylene industry for activation of ground granulated blastfurnace slag. Constr Build Mater 238:1–10

Li W, Yi Y, Puppala AJ (2022) Comparing carbide sludge-ground granulated blastfurnace slag and ordinary Portland cement: different findings from binder paste and stabilized clay slurry. Constr Build Mater 321:126382

Liu M, Carter J (2002) A structured cam clay model. Can Geotech J 39(6):1313–1332

Lorenzo GA, Bergado DT (2006) Fundamental characteristics of cement-admixed clay in deep mixing. J Mater Civ Eng 18(2):161–174

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. Wiley, New York

Pillai V S, Muhunthan B (1999) Landslides in cemented and normally consolidated soils: a review of failure mechanism using stress-path. In: Proceedings of 13th annual Vancouver Geotechnical Society Symposium, Vancouver, British Columbia.

Pitchumani NK, Islam A (2021) Reclamation and ground improvement of soft marine clay for development of offshore terminal 4, JNPT. Navi Mumbai Indian Geotech J 51(3):502–519

Rashad AM (2015) An exploratory study on high-volume fly ash concrete incorporating silica fume subjected to thermal loads. J Clean Prod 87:735–744

Sachan A, Penumadu D (2007) Effect of microfabric on shear behavior of kaolin clay. J Geotechn Geoenviron Eng 133(3):306–318

Salas DA, Ramirez AD, Rodríguez CR, Petroche DM, Boero AJ, Duque-Rivera J (2016) Environmental impacts, life cycle assessment and potential improvement measures for cement production: a literature review. J Clean Prod 113:114–122

Sharma NK, Swain S, Sahoo UC (2012) Stabilization of a clayey soil with fly ash and lime: a micro level investigation. Geotech Geol Eng 30(5):1197–1205

Shen Z, Gao F, Wang Z, Jiang M (2019) Evolution of mesoscale bonded particle clusters in cemented granular material. Acta Geotech 14(6):1653–1667

Wong I, Chua T (1999) Ground movements due to pile driving in an excavation in soft soil. Can Geotech J 36(1):152–160

Wood DM (1990) Soil behaviour and critical state soil mechanics. Cambridge University Press, Cambridge

Xiao H (2009) Yielding and failure of cement treated soil. PhD Thesis. National University of Singapore, Singapore.

Xiao H-W, Lee F-H (2014) An energy-based isotropic compression relation for cement-admixed soft clay. Géotechnique 64(5):412–418

Xu G (2013) Grain sorting behavior of dredged slurries in reclaimed land and its effects on engineering properties. PhD Thesis, Hohai University, Nanjing, China.

Xu B, Yi Y (2021) Soft clay stabilization using three industry byproducts. J Mater Civ Eng 33(5):06021002

Yi Y, Li C, Liu S, Jin F (2015) Magnesium sulfate attack on clays stabilised by carbide slag-and magnesia-ground granulated blast furnace slag. Geotechnique Lett 5(4):306–312

Yi Y, Gu L, Liu S (2015) Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl Clay Sci 103:71–76

Yi Y, Liu S, Puppala AJ, Xi P (2017) Vertical bearing capacity behaviour of single T-shaped soil–cement column in soft ground: laboratory modelling, field test, and calculation. Acta Geotech 12(5):1077–1088

Yi Y, Liu S, Puppala AJ (2018) Bearing capacity of composite foundation consisting of T-shaped soil-cement column and soft clay. Transportation Geotechnics 15:47–56

Yoobanpot N, Jamsawang P, Horpibulsuk S (2017) Strength behavior and microstructural characteristics of soft clay stabilized with cement kiln dust and fly ash residue. Appl Clay Sci 141:146–156

Yu F (2019) Influence of particle breakage on behavior of coral sands in triaxial tests. Int J Geomech 19(12):04019131

Zhang R, Santoso A, Tan T, Phoon K (2013) Strength of high water-content marine clay stabilized by low amount of cement. J Geotechn Geoenviron Eng 139(12):2170–2181

Zhang R, Zheng J, Bian X (2017) Experimental investigation on effect of curing stress on the strength of cement-stabilized clay at high water content. Acta Geotech 12(4):921–936

Zhu J-G, Yin J-H (2000) Strain-rate-dependent stress-strain behavior of overconsolidated Hong Kong marine clay. Can Geotech J 37(6):1272–1282

Acknowledgment

This research is supported by the Ministry of Education, Singapore, under its Academic Research Fund Tier 2 (MOE-T2EP50220-0004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, W., Yi, Y. & Puppala, A.J. Triaxial strength behavior of carbide sludge (CS)–ground-granulated blastfurnace slag (GGBS)-treated clay slurry. Acta Geotech. 17, 5585–5596 (2022). https://doi.org/10.1007/s11440-022-01601-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01601-w