Abstract

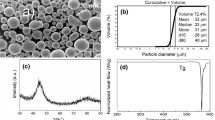

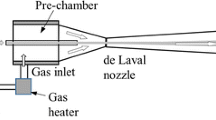

As compared to thermal spray techniques, cold spraying allows to retain metastable phases of the feedstock material like amorphous structures, due to lower process gas temperatures. Compared to crystalline metals, metallic glasses are brittle at ambient temperature but viscous at higher temperatures. Therefore, cold spray parameters must be optimized for conditions that allow softening of the amorphous spray material for successfully producing coatings. For this study, a FeCoCrMoBC metallic glass was used that in comparison to others offers advantages with respect to higher hardness, less costly feedstock powder, and minimum reactivity with the environment. Necessary impact conditions were investigated to meet the window of deposition in cold gas spraying. According to calculations and cold spray experiments, neither the glass transition temperature T g nor the melting temperature T m can describe required conditions for bonding. Thus, a so called softening temperature between the glass temperature and the melting temperature had to be defined to calculate the critical velocity of metallic glasses. With respect to the bonding mechanism, impact morphologies could prove that a transition to viscous flow gets more prominent for harsher spray conditions. By sufficiently exceeding the critical condition for bonding, coatings with rather dense microstructures can be processed at deposition efficiencies of about 70%. The coatings have a hardness of 1100 HV 0.3, but the results also demonstrate that further work is still needed to explore the full potential for bulk metallic glasses.

Similar content being viewed by others

References

G. Fritsch, Amorphous and Liquid Metals, Naturwissenschaften, 1988, 75, p 551-558

J. Schroers, The Superplastic Forming of Bulk Metallic Glasses, J. Manag., 2005, 57, p 35-39

J. Schroers and N. Paton, Amorphous Metal alloys Form Like Plastics, Adv. Mater. Process., 2006, 164, p 61-63

A.L. Greer, Confusion by Design, Nature, 1993, 366, p 303-304

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48, p 279-306

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54, p 729-742

J.F. Löffler, Bulk Metallic Glasses, Intermetallics, 2003, 11, p 529-540

Y.H. Liu, C.T. Liu, W.H. Wang, A. Inoue, T. Sakurai, and M.W. Chen, Thermodynamic Origins of Shear Band Formation and the Universal Scaling Law of Metallic Glass Strength, Phys. Rev. Lett., 2009, 103, p 065504-1-065504-4

F. Spaepen, Homogeneous Flow of Metallic Glasses: A Free Volume Perspective, Scr. Mater., 2006, 54, p 363-367

R. Huang, Z. Suo, J.H. Prevost, and W.D. Nix, Inhomogeneous Deformation in Metallic Glasses, J. Mech. Phys. Solids, 2002, 50, p 1011-1027

F. Shimizu, S. Ogata, and J. Li, Theory of Shear Banding in Metallic Glasses and Molecular Dynamics Calculations, Mater. Trans., 2007, 48, p 2923-2927

Y. Zhang and A.L. Greer, Thickness of Shear Bands in Metallic Glasses, Appl. Phys. Lett., 2006, 89, p 0719071-0719073

K. Georgarakis, M. Aljerf, Y. Li, A. LeMoulec, F. Charlot, A.R. Yavari, K. Chornokhvostenko, E. Tabachnikova, G.A. Evangelakis, D.B. Miracle, A.L. Greer, and T. Zhang, Shear Band Melting and Serrated Flow in Metallic Glasses, Appl. Phys. Lett., 2008, 93, p 0319071-0319073

J.F. Lewandowski and A.L. Greer, Temperature Rise at Shear Bands in Metallic Glasses, Nat. Mater., 2006, 5, p 15-18

H. Choi, S. Yoon, G. Kim, H. Jo, and C. Lee, Phase Evolutions of Bulk Amorphous NiTiZrSiSn Feedstock During Thermal and Kinetic Spraying Processes, Scr. Mater., 2005, 53, p 125-130

S. Yoon, H.J. Kim, and C. Lee, Deposition Behavior of Bulk Amorphous NiTiZrSiSn According to the Kinetic and Thermal Energy Levels in the Kinetic Spraying Process, Surf. Coat. Technol., 2006, 200, p 6022-6029

S. Yoon, C. Lee, H. Choi, H. Kim, and J. Bae, Impacting Behavior of Bulk Metallic Glass Powder at an Abnormally High Strain Rate During Kinetic Spraying, Mater. Sci. Eng., 2007, A 449-451, p 911-915

S. Yoon, J. Kim, G. Bae, B. Kim, and C. Lee, Formation of Coating and Tribological Behavior of Kinetic Sprayed Fe-Based Bulk Metallic Glass, J. Alloys Compd., 2011, 509, p 347-353

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18, p 794-808

T. Schmidt, F. Gärtner, and H. Kreye, New Developments in Cold Spray Based on Higher Gas and Particle Temperatures, J. Therm. Spray Technol., 2006, 15, p 488-494

A.S. Argon, Plastic Deformation in Metallic Glasses, Acta Metall., 1979, 27, p 47-58

P. Wadhwa, J. Heinrich, and R. Busch, Processing of Copper Fiber-Reinforced Zr41.2Ti13.8Cu12.5Ni10.0Be22.5 Bulk Metallic Glass Composites, Scr. Mater., 2007, 56, p 73-76

R. Busch, The Thermophysical Properties of Bulk Metallic Glass-Forming Liquids, J. Manang., 2000, 52, p 39-42

J. Schroers, Y. Wu, R. Busch, and W.L. Johnson, Transition from Nucleation Controlled to Growth Controlled Crystallization in Pd43Ni10Cu27P20 Melts, Acta Mater., 2001, 49, p 2773-2781

S. Yoon, G. Bae, Y. Xiong, S. Kumar, K. Kang, J.-J. Kim, and C. Lee, Strain-Enhanced Nanocrystallization of a CuNiTiZr Bulk Metallic Glass Coating by a Kinetic Spraying Process, Acta Mater., 2009, 57, p 6191-6199

S. Krebs, Warm Spraying of Amorphous and Nano-Crystalline FE-Base Alloys, Diploma Thesis, Helmut-Schmidt-University, 2007

Acknowledgements

The authors would like to thank the staff for support in the presented study, in alphabetical order Thomas Breckwoldt, Herbert Hübner, Dieter Müller, Norbert Németh, Camilla Schulze, Matthias Schulze and Uwe Wagener.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2011 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2011: Proceedings of the International Thermal Spray Conference, Hamburg, Germany, September 27-29, 2011, Basil R. Marple, Arvind Agarwal, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2011.

Rights and permissions

About this article

Cite this article

List, A., Gärtner, F., Schmidt, T. et al. Impact Conditions for Cold Spraying of Hard Metallic Glasses. J Therm Spray Tech 21, 531–540 (2012). https://doi.org/10.1007/s11666-012-9750-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9750-5