Abstract

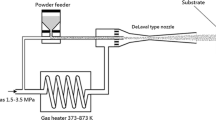

In cold spraying, the impact particle velocity plays a key role for successful deposition. It is well known that only those particles can achieve successful bonding which have an impact velocity exceeding a particular threshold. This critical velocity depends on the thermomechanical properties of the impacting particles at impacting temperature. The latter depends on the gas temperature in the torch but also on stand-off distance and gas pressure. In the past, some semiempirical approaches have been proposed to estimate particle impact and critical velocities. Besides that, there are a limited number of available studies on particle velocity measurements in cold spraying. In the present work, particle velocity measurements were performed using a cold spray meter, where a laser beam is used to illuminate the particles ensuring sufficiently detectable radiant signal intensities. Measurements were carried out for INCONEL® alloy 718-type powders with different particle sizes. These experimental investigations comprised mainly subcritical spray parameters for this material to have a closer look at the conditions of initial deposition. The critical velocities were identified by evaluating the deposition efficiencies and correlating them to the measured particle velocity distributions. In addition, the experimental results were compared with some values estimated by model calculations.

Similar content being viewed by others

References

DIN EN 657: Thermal Spraying—Terminology, Classification, 2005

V. Champagne and D. Helfritch, Critical Assessment 11: Structural Repairs by Cold Spray, Mater. Sci. Technol., 2014, 31(6), p 627-634

C. Slama and M. Abdellaoui, Structural Characterization of the Aged Inconel 718, J. Alloys Compd., 2000, 306, p 277-284

G.A. Rao, K.S. Prasad, M. Kumar, M. Srinivas, and D.S. Sarma, Characterisation of Hot Isostatically Pressed Nickel Base Superalloy Inconel* 718, Mater. Sci. Technol., 2003, 19(3), p 313-321

T. Marrocco, Development of Improved Cold Spray and HVOF Deposited Coatings, PhD thesis, University of Nottingham, 2008. http://eprints.nottingham.ac.uk/11453/1/493325.pdf

J. Karthikeyan and A. Kay, Cold Spray Technology: An Industrial Perspective. in Thermal Spray 2003: Advancing the Science and Applying the Technology. ed. by B.R. Marple, C. Moreau, May 5-8, 2003 (Orlando, FL), ASM International, 2003, Vol 1, p. 845 Vol 2, pp. 864, 117-121 (2003)

J. Kim, S. Lee, and C. Lee, Investigating the Cause of Hindrance to the Interfacial Bonding of INCONEL 718 Layer Deposited by Kinetic Spray Process, J. Korean Inst. Surf. Eng., 2015, 48(6), p 275-282

W. Wong, E. Irissou, P. Vo, M. Sone, F. Bernier, J.G. Legoux, H. Fukanuma, and S. Yue, Cold Spray Forming of Inconel 718, J. Therm. Spray Technol., 2012, 22(2-3), p 413-421

D. Levasseur, S. Yue, and M. Brochu, Pressureless Sintering of Cold Sprayed Inconel 718 Deposit, Mater. Sci. Eng. A, 2012, 556, p 343-350

M.A. Morris, E. Sauvain, and D.G. Morris, Post-Compaction Heat-Treatment Response of Dynamically-Compacted Inconel 718 Powder, J. Mater. Sci., 1987, 22, p 1509-1516

S. Yin, M. Meyer, W. Li, H. Liao, and R. Lupoi, Gas Flow, Particle Acceleration, and Heat Transfer in Cold Spray: A review, J. Therm. Spray Technol., 2016, 25(5), p 874-896

B. Jodoin, F. Raletz, and M. Vardelle, Cold Spray Modeling and Validation Using an Optical Diagnostic Method, Surf. Coat. Technol., 2006, 200(14-15), p 4424-4432

V.K. Champagne, D.J. Helfritch, S.P.G. Dinavahi, and P.F. Leyman, Theoretical and Experimental Particle Velocity in Cold Spray, J. Therm. Spray Technol., 2011, 20(3), p 425-431

G. Mauer, R. Vaßen, and D. Stöver, Comparison and Applications of DPV-2000 and Accuraspray-g3 Diagnostic Systems, J. Therm. Spray Technol., 2007, 16(3), p 414-424

K. Landes, Diagnostics in Plasma Spraying Techniques, Surf. Coat. Technol., 2006, 201(5), p 1948-1954

J.G. Legoux, E. Irissou, and C. Moreau, Effect of Substrate Temperature on the Formation Mechanism of Cold-Sprayed Aluminum, Zinc and Tin Coatings, J. Therm. Spray Technol., 2007, 16(5-6), p 619-626

J. Pattison, S. Celotto, A. Khan, and W. O’Neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surf. Coat. Technol., 2008, 202(8), p 1443-1454

H. Assadi, T. Schmidt, H. Richter, J.O. Kliemann, K. Binder, F. Gärtner, T. Klassen, and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process, J. Therm. Spray Technol., 1999, 8(4), p 576-582

B. Jodoin, L. Ajdelsztajn, E. Sansoucy, A. Zúñiga, P. Richer, and E.J. Lavernia, Effect of Particle Size, Morphology, and Hardness on Cold Gas Dynamic Sprayed Aluminum Alloy Coatings, Surf. Coat. Technol., 2006, 201(6), p 3422-3429

S.P. Pardhasaradhi, V. Venkatachalapathy, S.V. Joshi, and S. Govindan, Optical Diagnostics Study of Gas Particle Transport Phenomena in Cold Gas Dynamic Spraying and Comparison with Model Predictions, J. Therm. Spray Technol., 2008, 17(4), p 551-563

R. Huang and H. Fukanuma, Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits, J. Therm. Spray Technol., 2011, 21(3-4), p 541-549

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

A. Hölzer and M. Sommerfeld, New Simple Correlation Formula for the Drag Coefficient of Non-spherical Particles, Powder Technol., 2008, 184(3), p 361-365

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

H. Fukanuma, N. Ohno, B. Sun, and R. Huang, In-flight Particle Velocity Measurements with DPV-2000 in Cold Spray, Surf. Coat. Technol., 2006, 201(5), p 1935-1941

T. Hussain, D.G. McCartney, P.H. Shipway, and D. Zhang, Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components, J. Therm. Spray Technol., 2009, 18(3), p 364-379

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mauer, G., Singh, R., Rauwald, KH. et al. Diagnostics of Cold-Sprayed Particle Velocities Approaching Critical Deposition Conditions. J Therm Spray Tech 26, 1423–1433 (2017). https://doi.org/10.1007/s11666-017-0596-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0596-8