Abstract

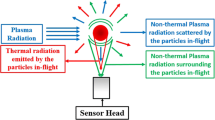

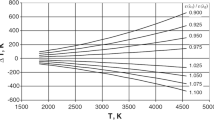

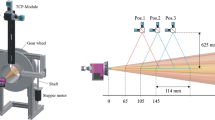

In cold spraying, powder particles are accelerated by preheated supersonic gas stream to high velocities and sprayed on a substrate. The particle velocities depend on the equipment design and process parameters, e.g., on the type of the process gas and its pressure and temperature. These, in turn, affect the coating structure and the properties. The particle velocities in cold spraying are high, and the particle temperatures are low, which can, therefore, be a challenge for the diagnostic methods. A novel optical online diagnostic system, HiWatch HR, will open new possibilities for measuring particle in-flight properties in cold spray processes. The system employs an imaging measurement technique called S-PTV (sizing-particle tracking velocimetry), first introduced in this research. This technique enables an accurate particle size measurement also for small diameter particles with a large powder volume. The aim of this study was to evaluate the velocities of metallic particles sprayed with HPCS and LPCS systems and with varying process parameters. The measured in-flight particle properties were further linked to the resulting coating properties. Furthermore, the camera was able to provide information about variations during the spraying, e.g., fluctuating powder feeding, which is important from the process control and quality control point of view.

Similar content being viewed by others

References

V. Champagne, Ed., The Cold Spray Materials Deposition Process: Fundamentals and Applications, Woodhead Publishing Ltd., Cambridge, 2007, p 362

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkimov, and V. Fomin, Cold Spray Technology, 1st ed., Elsevier, Netherlands, 2007, p 328

T. Stoltenhoff, H. Kreye, and H. Richter, An Analysis of the Cold Spray Process and its Coatings, J. Therm. Spray Technol., 2001, 11(4), p 542-550

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

A. Alkhimov, S. Klinkov, and V. Kosarev, Experimental Study of Deformation and Attachment of Microparticles to an Obstacle Upon High-Rate Impact, J. Appl. Mech. Tech. Phys., 2000, 41(2), p 245-250

X.-J. Ning, J.-H. Jang, H.-J. Kim, C.-J. Li, and C. Lee, Cold Spraying of Al-Sn Binary Alloy: Coating Characteristics and Particle Bonding Features, Surf. Coat. Technol., 2008, 202(9), p 1681-1687

M. Jeandin, H. Koivuluoto, and S. Vezzu, 4 Coating Properties, Modern Cold Spray, Materials, Process, and Applications ed. by J. Villafuerte (Springer, 2015), p 107-224

S. Shin, S. Yoon, Y. Kim, and C. Lee, Effect of Particle Parameters on the Deposition Characteristics of a Hard/Soft-Particles Composite in Kinetic Spraying, Surf. Coat. Technol., 2006, 201, p 3457-3461

L. Pouliot, 8 Quality Assurance, Modern Cold Spray, Materials, Process, and Applications ed. by J. Villafuerte, (Springer, 2015), p 303-316

S. Yin, M. Meyer, W. Li, H. Liao, and R. Lupoi, Gas Flow Particle Acceleration, and Heat Transfer in Cold Spray: A review, J. Therm. Spray Technol., 2016, 25(5), p 874-896

T. Van Steenkiste, J. Smith, and R. Teets, Aluminum Coatings via Kinetic Spray with Relatively Large Powder Particles, Surf. Coat. Technol., 2002, 154, p 237-252

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54, p 729-742

X.-J. Ning, J.-H. Jang, and H.-J. Kim, The Effects of Powder Properties on In-Flight Particle Velocity and Deposition Process During Low Pressure Cold Spray Process, Appl. Surf. Sci., 2007, 253(18), p 7449-7455

H. Koivuluoto, Microstructural Characteristics and Corrosion Properties of Cold-Sprayed Coatings, Doctoral Thesis, Tampere University of Technology, Tampereen Yliopistopaino Oy, Tampere, 2010

T. Hussain, S. Yue, and C.-J. Li, 3 Characteristics of Feedstock Materials, Modern Cold Spray, Materials, Process, and Applications ed. by J. Villafuerte, (Springer, 2015), p 73-106

J. Larjo, High-Power Diode Lasers in Spray Process Diagnostics, SPIE, 2005, https://doi.org/10.1117/12.567358

Edmund Optics, Inc.: https://www.edmundoptics.com/resources/application-notes/imaging/advantages-of-telecentricity/, June 2017

H. Koivuluoto, A. Coleman, K. Murray, M. Kearns, and P. Vuoristo, High-Pressure Cold Sprayed (HPCS) and Low Pressure Cold Sprayed (LPCS) Coatings Prepared From OFHC Cu Feedstock—Overview From Powder Characteristics to Coating Properties, J. Therm. Spray Technol., 2012, 21(5), p 1065-1075

H. Koivuluoto, and P. Vuoristo, Structural Analysis of Cold-Sprayed Nickel-Based Metallic and Metallic-Ceramic Coatings, J. Therm. Spray Technol., 2010, 19(5), p 975-989

H. Koivuluoto, G. Bolelli, A. Milanti, L. Lusvarghi, and P. Vuoristo, Microstructural Analysis of High-Pressure Cold-Sprayed Ni, NiCu and NiCu + Al2O3 Coatings, Surf. Coat. Technol., 2015, 268, p 224-229

M. Gauthier, Engineering Data for Metals and Alloys, Metals Handbook Desk Edition, ASM International, 1998, p 64-84

T. Kairet, G. Di Stefano, M. Degrez, F. Campana, and J.-P. Janssen, Comparison Between Coatings from two Different Copper Powders: Mechanical Properties, Hardness and Bond Strength, Thermal Spray 2006: Building on 100 Years of Success, ed. by B. Marple, M. Hyland, Y.-C. Lau, R. Lima, and J. Voyer, May 15-18, 2006, Seattle, Washington, USA

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano, and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Surf. Eng., 2014, 30(6), p 369-395

Y.T.R. Lee, H. Ashrafizadeh, G. Fisher, and A. McDonald, Effect of Type of Reinforcing Particles on the Deposition Efficiency and Wear Resistance of Low-Pressure Cold-Sprayed Metal Matrix Composite Coatings, Surf. Coat. Technol., 2017, 324, p 190-200

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

T. Van Steenkiste and D.W. Gorkiewicz, Analysis of Tantalum Coatings Produced by the Kinetic Spray Process, J. Therm. Spray Technol., 2004, 13(2), p 265-273

T.S. Price, P.H. Shipway, D.G. McCartney, E. Calla, and D. Zhang, A Method for Characterizing the Degree of Inter-Particle Bond Formation in Cold Sprayed Coatings, J. Therm. Spray Technol., 2007, 16(4), p 566-570

P.S. Phani, D.S. Rao, S.V. Joshi, and G. Sundararajan, Effect of Process Parameters and Heat Treatments on Properties of Cold Sprayed Copper Coatings, J. Therm. Spray Technol., 2007, 16(3), p 425-434

Acknowledgments

The work has been done within DIMECC Ltd. and its HYBRIDS program. The authors gratefully acknowledge the financial support from Tekes (Finnish Funding Agency for Technology and Innovation) and the participating companies. Also, the authors would like to thank Mr. Mikko Kylmälahti, of Tampere University of Technology, for spraying experiments and M.Sc. Juha Lagerbom, of VTT (Finland), for measuring particle size distributions by laser diffraction technique.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koivuluoto, H., Matikainen, V., Larjo, J. et al. Novel Online Diagnostic Analysis for In-Flight Particle Properties in Cold Spraying. J Therm Spray Tech 27, 423–432 (2018). https://doi.org/10.1007/s11666-018-0685-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0685-3