Abstract

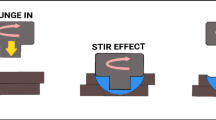

Friction stir welding (FSW) is a relatively new joining process and is being used commercially in several industry sectors. In small and medium enterprises, however, this novel technology has not been applied despite its remarkable advantages because of the drawbacks of FSW. A database has been assembled and drawbacks have been analyzed then solved appropriately in the Industry-Government-Academia Collaboration Project. As an outgrowth, the optimum and individual know-how of practical FSW technology could be transferred to medium and small enterprises.

Similar content being viewed by others

References

C.J. Dawes and W.H. Thomas, Weld. J, 75 (1996), pp. 41–45.

T. Tanaka et al., J. Japan Inst. Light Metals, 57 (2007), pp. 549–553 (Japanese).

T. Hirata et al., J. JFJA, 7 (2008), pp. 25–30 (Japa nese).

H.J. Liu et al., Sci. Tech. Weld. Join., 8 (2003), pp. 450–454.

Y.S. Sato et al., Mater. Sci. Eng. A, 369 (2004), pp. 138–143.

Y.S. Sato et al., Mat. Sci. Eng. A, 354 (2003), pp. 298–305.

T. Hirata et al., Mater. Sci. Eng. A, 456 (2007), pp. 344–349.

H.J. Liu et al., J. Mater. Process. Tech., 142 (2003), pp. 692–696.

C. Genevois et al., Acta Mater., 53 (2005), pp. 2447–2458.

M.A. Sutton et al., Mater. Sci. Eng. A, 354 (2003), pp. 6–16.

K. Elangovan and V. Balasubramanian, Mater. Design, 29 (2008), pp. 362–373.

D. C. Hofmann and K. S. Vecchio, Mater. Sci. Eng. A 402 (2005), pp. 234–241.

P. Cavaliere et al., J. Mater. Process. Tech., 180 (2006), pp. 263–270.

L. Fratini and G. Buffa, Int. J. Machine Tools & Manufacture, 45 (2005), pp. 1188–1194.

P. Cavaliere and A. Squillace, Mater. Character., 55 (2005), pp. 136–142.

J.-Q. Su, T.W. Nelson, and C.J. Sterling, Mater. Sci. Eng. A, 405 (2005), pp. 277–286.

M. Dumont et al., Acta Mater., 54 (2006), pp. 4793–4801.

J.A. Esparza et al., J. Mater. Sci. Lett., 21 (2002), pp. 917–920.

W. Xunhong and W. Kuaishe, Mater. Sci. Eng. A, 431 (2006), pp. 114–117.

M.B. Kannan et al., Mater. Sci. Eng. A, 460–461 (2007), pp. 243–250.

N. Afrin et al., Mater. Sci. Eng. A, 472 (2008), pp. 179–186.

S.H.C. Park, Y.S. Sato, and H. Kokawa, Scr. Mater., 49 (2003), pp. 161–166.

J.A. Esparza, W.C. Davis, and L.E. Murr, J. Mater. Sci., 38 (2003), pp. 941–952.

S.H.C. Park, Y.S. Sato, and H. Kokawa, J. Mater. Sci., 38 (2003), pp. 4379–4383.

M. Tsujikawa et al., Mater. Trans., 47 (2006), pp. 1077–1081.

K. Colligan et al., Proc. 3rd Int. FSWSymp. (Cambridge, U.K.: The Welding Institute, 2001).

J.K. Kristensen et al., Proc. 5th Int. FSW Symp. (Cambridge, U.K.: The Welding Institute, 2004).

G. Luetjering and J.C. Williams, Titanium (Berlin: Springer, 2003).

M.J. Donachie Jr., Titanium; A Technical Guide (Metals Park, OH: ASM International, 1988), pp. 131–141.

M. Ikeda et al., Proc. 6th Int. FSW Symp. (Cambridge, U.K.: The Welding Institute, 2006).

S. Oki et al., Mater. Sci. Forum, 539–543 (2007), pp. 3838–3843.

S. Oki et al., Proc. 6th Int. FSWSymp. (Cambridge, U.K.: The Welding Institute, 2006).

Y. Okawa et al., Welding Tech., 55 (2007), pp. 71–75 (Japanese).

M. Tsujikawa et al., Mater. Trans., 46 (2005), pp. 3081–3084.

M. Tsujikawa et al., Mater. Trans., 48 (2007), pp. 618–621.

J. Kobata et al., Mater. Lett., 61 (2007), pp. 3771–3773.

T. Hirata et al., Scr. Mater., 56 (2007), pp. 477–480.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hirata, T., Higashi, K. The use of friction stir welding for manufacturing small-scale structures. JOM 62, 42–48 (2010). https://doi.org/10.1007/s11837-010-0030-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-010-0030-x