Abstract

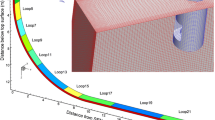

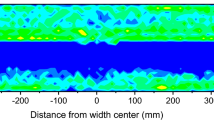

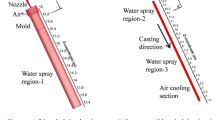

Understanding the entrapment of inclusions in the solidifying shell within a steel continuous-casting strand is important to predict and improve the internal quality of the steel product. The current work presents two approaches to predict the particle entrapment in the full length of a billet caster. First, the sink term approach assumed a cone-shaped solidification shell and ignored the heat transfer and solidification, and sink terms were added to the equations to represent the mass loss and momentum loss during solidification. The inclusions were entrapped once they touched the shell. Second, full solidification considered the effect of turbulent flow, heat transfer, solidification, and the motion of inclusions. Inclusions were entrapped once they moved to the location with a liquid fraction of 0.6. The calculated inclusion distribution in the billet by the full solidification approach agreed with the industrial measurement better than the sink term approach. For future study, the effects of the inclusion size and the first arm spacing on the entrapment of inclusions will be included in the full solidification approach.

Similar content being viewed by others

References

H. Yasuda, I. Ohnaka, and H. Jozuka, ISIJ Int. 44, 1366 (2004).

S.N. Omenyi and A.W. Neumann, J. Appl. Phys. 47, 3956 (1976).

H. Shibata, H.Y.S. Yoshinaga, and T.E.M. Suzuki, ISIJ Int. 38, 149 (1998).

Q. Yuan, Transient Study of Turbulent Flow and Particle Transport During Continuous Casting of Steel Slabs (Ph.D. Thesis, University of Illinois at Urbana-Champaign, 2004).

M. Javurek, P. Gittler, R. Rössler, B. Kaufmann, and H. Preßlinger, Steel Res. Int. 76, 65 (2005).

C. Pfeiler, B.G. Thomas, M. Wu, A. Ludwig, and A. Kharicha, Steel Res. Int. 77, 1 (2006).

Q. Yuan and B.G. Thoma, ICS 2005—The 3rd International Congress on the Science and Technology of Steelmaking (Warrendale, PA: AIST, 2005), pp. 745–759.

Q. Yuan, B.G. Thomas, and S.P. Vanka, Metall. Mater. Trans. B 35B, 703 (2004).

K. Cukierski and B.G. Thomas, Metall. Mater. Trans. B 39B, 94 (2008).

S. Yang, L. Zhang, J. Li, and K.D. Peaslee, Proc. AISTech 2011 Iron & Steel Technology Conference and Exposition, vol. II (Warrendale, PA: AIST, 2011).

Y. Wang and L. Zhang, Proc. Jim Evans Honorary Symposium, ed. B.Q. Li, B.G. Thomas, L. Zhang, F.M. Doyle and A.P. Campbell (Warrendale, PA: TMS, 2010), pp. 207–215.

L. Zhang, S. Yang, X. Wang, K. Cai, J. Li, X. Wan, and B.G. Thomas, Metall. Mater. Trans. B 38B, 63 (2007).

L. Zhang, Proc. Fifth Int. Conf. Computational Fluid Dynamics in the Process Industries (CFD2006) (Clayton, Australia: CSIRO, 2006).

L. Zhang, Light Metals 2006, ed. T.J. Galloway (Warrendale, PA: TMS, 2006), pp. 659–668.

X. Wang and L. Zhang, AISTech 2006, vol. II (Warrendale, PA: AIST, 2006), pp. 371–379.

L. Zhang, S. Yang, X. Wang, K. Cai, J. Li, X. Wan, and B.G. Thomas, AISTech2004 (Warrendale, PA: ISS, 2004), pp. 879–894.

L. Zhang and B.G. Thomas, Proc. XXIV Steelmaking National Symposium (Melbourne, Australia: CSIRO, 2003), pp. 184–198.

B.G. Thomas and L. Zhang, ISIJ Int. 41, 1181 (2001).

N. Bessho, R. Yoda, H. Yamasaki, T. Fujii, T. Nozaki, and S. Takatori, Iron Steelmaker 18, 39 (1991).

I. Sawada, H. Tanaka, and I. Takigawa, Proc. Sixth Int. Iron and Steel Congress, vol. 3 (Nagoya, Japan: The Iron and Steel Institute of Japan, 1990), pp. 334–347.

E. Loth, Progr. Energy Combust. Sci. 26, 161 (2000).

L. Zhang, J. Aoki, and B.G. Thomas, Metall. Mater. Trans. B 37B, 361 (2006).

L. Zhang and S. Taniguchi, Int. Mater. Rev. 45, 59 (2000).

Fluent, Inc., FLUENT6.1-Manual (Lebanon, NH: Fluent, Inc., 2003).

H. Zhang (Thesis, Hebei Polytechnic University, 2007).

V.R. Voller and C. Prakash, Int. J. Heat Mass Transf. 30, 1709 (1987).

V.R. Voller, A.D. Brent, and K.J. Reid, A Computational Modeling Framework for the Analysis of Metallurgical Solidification Process and Phenomena (Paper presented at the Conference for Solidifcation Processing, Sheffield, U.K., 1987).

M. Yamazaki, Y. Natsume, H. Harada, and K. Ohsasa, ISIJ Int. 46, 903 (2006).

W. Lu, Study of Dynamic Control Model for Secondary Cooling Zone of Continuous Casting (Thesis, Hebei Polytechnic University, 2007).

Y. Wang and L. Zhang, Metall. Mater. Trans. B (2013), in press.

M. Long, L. Zhang, and F. Lu, ISIJ Int. 50, 1792 (2010).

D. Gupta and A.K. Lahiri, Metall. Mater. Trans. B 27B, 757 (1996).

E. Torres-Alonso and R.D. Morales, Metall. Mater. Trans. B 39B, 840 (2008).

Q. Yuan, S. Sivaramakrishnan, S.P. Vanka, and B.G. Thomas, Metall. Mater. Trans. B 35B, 967 (1996).

L. Zhang, J. Zhi, F. Mei, L. Zhu, X. Jiang, J. Shen, J. Cui, K. Cai, and B.G. Thomas, Ironmaking Steelmaking 33, 129 (2006).

L. Zhang, B.G. Thomas, K. Cai, L. Zhu, and J. Cui, ISSTech2003 (Warrendale, PA: ISS, 2003), pp. 141–156.

L. Zhang and B.G. Thomas, ISIJ Int. 43, 271 (2003).

Acknowledgements

This research is supported by the High Quality Steel Consortium (HQSC) and the Laboratory of Green Process Metallurgy and Modeling (GPMM) at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Wang, Y. Modeling the Entrapment of Nonmetallic Inclusions in Steel Continuous-Casting Billets. JOM 64, 1063–1074 (2012). https://doi.org/10.1007/s11837-012-0421-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0421-2