Abstract

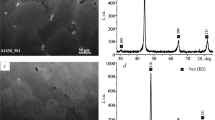

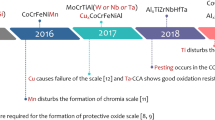

High-entropy alloys (HEAs) are a class of alloys that are being considered for a number of applications. In the present study, the microstructures and 1050°C oxidation behaviors of two HEAs, Al10Cr22.5Co22.5Ni22.5Fe22.5 (at.%) and Al20Cr25Co25Ni25Si5 have been investigated along with Al15Cr10Co35Ni35Si5, which is a high-temperature shape-memory alloy. Oxide formation occurred via selective oxidation in a manner that was consistent with the oxide formation model devised by Giggins and Pettit for model Ni-Cr-Al alloys. The lower Al content alloy formed an external Cr2O3 scale and an internal subscale consisting of Al2O3 and AlN precipitates. The higher Al content alloys exhibited smaller mass gains and formed external Al2O3 scales without any internal oxidation of the alloys.

Similar content being viewed by others

References

W.-H. Wu, C.-C. Yang, and J.-W. Yeh, Ann. Chim. Sci. Mater. 31, 737 (2006).

J.W. Yeh, Y.L. Chen, S.J. Lin, and S.K. Chen, Mater. Sci. Forum 560, 1 (2007).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

Y. Zhang and Z. Yunjun, Mater. Sci. Forum 561–565, 1337 (2007).

D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley, Entropy 16, 494 (2014).

J.-W. Yeh, JOM 65, 1759 (2013).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Progr. Mater. Sci. 61, 1 (2014).

P.K. Huang, J.W. Yeh, T.T. Shun, and S.K. Chen, Adv. Eng. Mater. 6, 74 (2004).

T.-T. Shun, C.-H. Hung, and C.-F. Lee, J. Alloys Compd. 493, 105 (2010).

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu, Mater. Sci. Eng. A 527, 7210 (2010).

A. Cunliffe, J. Plummer, I. Figueroa, and I. Todd, Intermetallics 23, 204 (2012).

S. Guo, Q. Hu, C. Ng, and C.T. Liu, Intermetallics 41, 96 (2013).

C. Zhang, F. Zhang, S. Chen, and W. Cao, JOM 64, 839 (2012).

A.K. Singh and A. Subramaniam, J. Alloy Compd. 587, 113 (2014).

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, W.S. Cao, and U.R. Kattner, CALPHAD 45, 1 (2014).

S.-T. Chen, W.-Y. Tang, Y.-F. Kuo, S.-Y. Chen, C.-H. Tsau, T.-T. Shun, and J.-W. Yeh, Mater. Sci. Eng. A 527, 5818 (2010).

J. Jiang and X. Luo, Adv. Mater. Res. 652–654, 1115 (2013).

H. Zhang, Q.T. Wang, Q.H. Tang, and P.Q. Dai, Corros. Protec. 34, 561 (2013).

M.-H. Chuang, M.-H. Tsai, W.-R. Wang, S.-J. Lin, and J.-W. Yeh, Acta Mater. 59, 6308 (2011).

M.-H. Hsieh, M.-H. Tsai, W.-J. Shen, and J.-W. Yeh, Surf. Coat. Technol. 221, 118 (2013).

C. Huang, Y. Zhang, J. Shen, and R. Vilar, Surf. Coat. Technol. 206, 1389 (2011).

C.M. Liu, H.M. Wang, S.Q. Zhang, H.B. Tang, and A.L. Zhang, J. Alloy Compd. 583, 162 (2014).

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle, J. Mater. Sci. 47, 6522 (2012).

W.J. Shen, M.H. Tsai, K.Y. Tsai, C.C. Juan, C.W. Tsai, J.W. Yeh, and Y.S. Chang, J. Electrochem. Soc. 160, C531 (2013).

K.-H. Cheng, C.-W. Tsai, S.-J. Lin, and J.-W. Yeh, J. Phys. D Appl. Phys. 44, 205405 (2011).

D. Tomus and H.P. Ng, Micron 44, 115 (2013).

ES Vision (FEI-Company, Hillsboro, OR, 2004).

M.C. Flemmings, Solidification Processing (New York: McGraw-Hill, 1974).

W. Kurz and D.J. Fisher, Fundamentals of Solidification (Dürnten: Trans Tech Publications Ltd., 1998).

H. Fredriksson and U. Åkerlind, Materials Processing During Casting (Hoboken: Wiley, 2006).

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, and J.-W. Yeh, Intermetallics 26, 44 (2012).

W.-R. Wang, W.-L. Wang, and J.-W. Yeh, J. Alloy Compd. 589, 143 (2014).

R.E. Reed-Hill and R. Abbaschian, Physical Metallurgy Principles, Second Edition (Boston: PWSKent, 1992).

B. Bartova, N. Wiese, D. Schryvers, J.N. Chapman, and S. Ignacova, Acta Mater. 56, 4470 (2008).

H.E. Karaca, I. Karaman, D.C. Lagoudas, H.J. Maier, and Y.I. Chumlyakov, Scripta Mater. 49, 831 (2003).

P.L. Potapov, P. Ochin, J. Pons, and D. Schryvers, Acta Mater. 48, 3833 (2000).

Y. Tanaka, T. Ohmori, K. Oikawa, R. Kainuma, and K. Ishida, Metall. Mater. Trans. 45, 427 (2004).

H.M. Daoud, A. Manzoni, R. Volkl, N. Wanderka, and U. Glatzel, JOM 65, 1805 (2013).

D. Schryvers, P. Boullay, P.L. Potapov, R.V. Kohn, and J.M. Ball, Int. J. Solids Struct. 39, 3543 (2002).

C.S. Giggins and F.S. Pettit, J. Electrochem. Soc. 118, 1782 (1971).

U. Krupp and H.J. Christ, Metall. Mater. Trans. A 31, 47 (2000).

S. Han and D.J. Young, Oxid. Met. 55, 223 (2001).

H. Ackermann, G. Teneva-Kosseva, H. Köhne, K. Lucka, S. Richter, and J. Mayer, Mater. Corros. 59, 380 (2008).

M.P. Brady, Y. Yamamoto, B.A. Pint, M.L. Santella, P.J. Maziasz, and L.R. Walker, High Temperature Corrosion and Protection of Materials, ed. P. Steinmetz, I.G. Wright, A. Galerie, D. Monceau, and S. Mathieu (Dürnten: TransTech Publications Ltd., 2008), pp. 725–732.

I. Peter, A. Zago, M. ActisGrande, and D. Ugues, Surf. Coat. Technol. 203, 1776 (2009).

C. Jang, D. Kim, D. Kim, I. Sah, W.-S. Ryu, and Y.-S. Yoo, Trans. Nonfer. Metals Soc. China 21, 1524 (2011).

J.P. Alfano (Ph.D. dissertation, The University of Alabama, 2013).

G.B. Gibbs and R. Hales, Corros. Sci. 17, 487 (1977).

Y. Shida, G.C. Wood, F.H. Stott, D.P. Whittle, and B.D. Bastow, Corros. Sci. 21, 581 (1981).

P. Kofstad, High Temperature Corrosion (New York: Elsevier, 1988).

N. Birks, G.H. Meier, and F.S. Pettit, High-Temperature Oxidation of Metals, 2nd ed. (Cambridge: Cambridge University Press, 2006).

D. Young, High Temperature Oxidation and Corrosion of Metals (Philadelphia: Elsevier, 2008).

T.M. Butler and M.L. Weaver, The University of Alabama, unpublished research (2014).

V.P. Deodeshmukh, S.J. Matthews, and D.L. Klarstrom, Int. J. Hydrog. Energy 36, 4580 (2011).

X. Ledoux, S. Mathieu, M. Vilasi, Y. Wouters, P. Del-Gallo, and M. Wagner, Oxid. Met. 80, 25 (2013).

G.R. Wallwork and A.Z. Hed, Oxid. Met. 3, 171 (1971).

J.-W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006).

S.-Y. Chang, C.-E. Li, Y.-C. Huang, H.-F. Hsu, J.-W. Yeh, and S.-J. Lin, Structural and Thermodynamic Factors of Suppressed Interdiffusion Kinetics in Multi-component High Entropy Materials (Scientific Report) (New York: Macmillan Publishers Limited, 2014).

Z. Tang, L. Huang, W. He, and P.K. Liaw, Entropy 16, 895 (2014).

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Acta Mater. 61, 4887 (2013).

S.C. Middleburgh, D.M. King, G.R. Lumpkin, M. Cortie, and L. Edwards, J. Alloy Compd. 599, 179 (2014).

G.R. Wallwork, Oxid. Met. 3, 213 (1971).

P. Tomaszewicz and G.R. Wallwork, Rev. High Temp. Mater. 4, 75 (1978).

F.H. Stott and G.C. Wood, Corros. Sci. 11, 799 (1971).

J.L. Smialek and G.H. Meier, Superalloys II, ed. C.T. Sims, N.S. Stoloff, and W.C. Hagel (New York: Wiley, 1987), pp. 293–326.

Y. Yamamoto, M.P. Brady, Z.P. Lu, P.J. Maziasz, C.T. Liu, B.A. Pint, K.L. More, H.M. Meyer, and E.A. Payzant, Science 316, 433 (2007).

M.P. Brady, Y. Yamamoto, Z.P. Lu, P.J. Maziasz, C.T. Liu, B.A. Pint, and M.L. Santella, Stainl. Steel World 20, 1 (2008).

I. Baker, H. Wu, X. Wu, M.K. Miller, and P.R. Munroe, Mater. Charact. 62, 952 (2011).

R.D. Heidenreich and E.A. Nesbitt, J. Appl. Phys. 23, 352 (1952).

Acknowledgement

This work used resources owned and maintained by the Central Analytical Facility (CAF), which is supported by the University of Alabama.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Butler, T.M., Alfano, J.P., Martens, R.L. et al. High-Temperature Oxidation Behavior of Al-Co-Cr-Ni-(Fe or Si) Multicomponent High-Entropy Alloys. JOM 67, 246–259 (2015). https://doi.org/10.1007/s11837-014-1185-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1185-7