Abstract

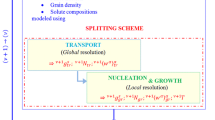

Prediction of solidification defects, such as macrosegregation and inhomogeneous microstructures, constitutes a key issue for industry. The development of models of casting processes needs to account for several imbricated length scales and different physical phenomena. For example, the kinetics of the growth of microstructures needs to be coupled with the multiphase flow at the process scale. We introduce such a state-of-the-art model and outline its principles. We present the most recent applications of the model to casting of a heavy steel ingot and to direct chill casting of a large Al alloy sheet ingot. Their ability to help in the understanding of complex phenomena, such as the competition between nucleation and growth of grains in the presence of convection of the liquid and of grain motion is shown, and its predictive capabilities are discussed. Key issues for future developments and research are addressed.

Similar content being viewed by others

References

J.A. Dantzig and M. Rappaz, Solidification, 1st ed. (Lausanne: EPFL Press, 2009).

C. Beckermann, Int. Mater. Rev. 47, 243 (2002).

G. Lesoult, Mater. Sci. Eng. A 414, 19 (2005).

J. Ni and C. Beckermann, Metall. Trans. B 22B, 349 (1991).

D.R. Poirier, P.J. Nandapurkar, and S. Ganesan, Metall. Trans. B 22, 889 (1991).

P. Bousquet-Melou, B. Goyeau, M. Quintard, F. Fichot, and D. Gobin, Int. J. Heat Mass Transf. 45, 3651 (2002).

S. Whitaker, Transp. Porous Media 25, 27 (1996).

B. Goyeau, T. Benihaddadene, D. Gobin, and M. Quintard, Metall. Mater. Trans. B 30, 613 (1999).

C.Y. Wang, S. Ahuja, C. Beckermann, and H.C. De Groh, Metall. Mater. Trans. B 26, 111 (1995).

C.-A. Gandin, G. Guillemot, B. Appolaire, and N.T. Niane, Mater. Sci. Eng. A 342, 44 (2003).

B. Appolaire, H. Combeau, and G. Lesoult, Mater. Sci. Eng. A 487, 33 (2008).

M. Založnik and H. Combeau, Comput. Mater. Sci. 48, 1 (2010).

H. Combeau, M. Založnik, S. Hans, and P.E. Richy, Metall. Mater. Trans. B 40, 289 (2009).

M. Bedel (Ph.D. Dissertation, Université de Lorraine, Nancy, France (2014).

M. Bedel, K.O. Tveito, M. Založnik, H. Combeau, and M. M’Hamdi, Comput. Mater. Sci. 102, 95 (2015).

M. Rappaz, Int. Mater. Rev. 34, 93 (1989).

G. Lesoult, H. Combeau, and M. Moukassi, J. Phys. IV 3, 813 (1993).

E. Liotti, A. Lui, R. Vincent, S. Kumar, Z. Guo, T. Connolley, I.P. Dolbnya, M. Hart, L. Arnberg, R.H. Mathiesen, and P.S. Grant, Acta Mater. 70, 228 (2014).

H. Neumann-Heyme, K. Eckert, and C. Beckermann, Phys. Rev. E 92, 1 (2015).

T.E. Quested and A.L. Greer, Acta Mater. 53, 2683 (2005).

M. Založnik, A. Kumar, H. Combeau, M. Bedel, P. Jarry, and E. Waz, Adv. Eng. Mater. 13, 570 (2011).

H. Combeau, A. Kumar, M. Založnik, I. Poitrault, G. Lacagne, A. Gingell, T. Mazet, and G. Lesoult, International Conference Ingot Casting, Rolling, and Forging (Aachen, Germany, 2012), pp. 27.

J.P. Gu and C. Beckermann, Metall. Mater. Trans. A 30, 1357 (1999).

M.C. Flemings and G.E. Nereo, Trans. Metall. Soc. AIME 239, 1449 (1967).

M. Založnik and H. Combeau, Modeling of Casting Welding and Advanced Solidification Processes XII, ed. S.L. Cockroft and D.M. Maijer (Warrendale, PA: TMS, 2009), pp. 165.

N. Leriche, H. Combeau, C.-A. Gandin, M. Založnik, and I.O.P. Conf, Ser. Mater. Sci. Eng. 84, 012087 (2015).

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, and D.J. Bristow, Acta Mater. 48, 2823 (2000).

M. Bedel, L. Heyvaert, M. Založnik, H. Combeau, D. Daloz, G. Lesoult, and I.O.P. Conf, Ser. Mater. Sci. Eng. 84, 012100 (2015).

A. Joly, G.-U. Grün, D. Daloz, H. Combeau, and G. Lesoult, Mater. Sci. Forum 329–330, 111 (2000).

A. Tronche, Ph.D. Dissertation, University of Cambridge (2000).

G. Lesoult, V. Albert, B. Appolaire, H. Combeau, D. Daloz, A. Joly, C. Stomp, G.-U. Grün, and P. Jarry, Sci. Technol. Adv. Mater. 2, 285 (2001).

D. Daloz, H. Combeau, A. Joly, G. Lesoult, G.-U. Grün, P. Jarry, and B. Commet, Matériaux 2002, de la conception à la mise en oeuvre (Tours, France, 2002).

K.O. Tveito, M. Bedel, M. Založnik, H. Combeau, M. M’Hamdi, and I.O.P. Conf, Ser. Mater. Sci. Eng. 27, 012040 (2012).

H. Yu and D.A. Granger, Aluminium Alloys: Their Physical and Mechanical Properties (Sheffield: EMAS, 1986), pp. 17.

T.L. Finn, M.G. Chu, and W.D. Bennon, Micro/Macro Scale Phenomena in Solidification, eds. C. Beckermann, L.A. Bertram, S.J. Pien, and R.E. Smelser (New York: ASME, 1992), pp. 17.

D.G. Eskin, Physical Metallurgy of Direct Chill Casting of Aluminum Alloys (Boca Raton: CRC Press, 2008).

D.G. Eskin, R. Nadella, and L. Katgerman, Acta Mater. 56, 1358 (2008).

R. Nadella, D.G. Eskin, and L. Katgerman, Metall. Mater. Trans. A 39, 450 (2008).

R. Nadella, D.G. Eskin, Q. Du, and L. Katgerman, Prog. Mater Sci. 53, 421 (2008).

D.G. Eskin, A. Jafari, and L. Katgerman, Mater. Sci. Technol. 27, 890 (2011).

Acknowledgements

The authors are grateful to the French State for support through the program “Investment in the future” operated by the National Research Agency (ANR) and referenced by ANR-11 LABX-0008-01 (LabEx DAMAS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Combeau, H., Založnik, M. & Bedel, M. Predictive Capabilities of Multiphysics and Multiscale Models in Modeling Solidification of Steel Ingots and DC Casting of Aluminum. JOM 68, 2198–2206 (2016). https://doi.org/10.1007/s11837-016-1993-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-1993-z