Abstract

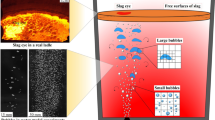

Insights into dispersed phases, such as bubbles and droplets, and multiscale interfaces in a gas-stirred ladle are of great significance to multiphase systems of metallurgical reactors, but are still challenging and not fully understood. A direct numerical simulation of dispersing phases was developed, coupling a sub-grid-scale large-eddy simulation for turbulence in fine grids with local refinement tactics. After validation with experimental data, the model was applied to investigate the bubble formation process at small length scales to understand the mechanism of bubble breakup and coalescence, to reveal the interaction of bubbles with surrounding fluid and the evolution of heterogeneous vortexes structures, to compare transient phenomena and time-averaged behavior, and to resolve the large-scale interface profile and the large number of small droplets formed by the interaction of metal, slag, and gas. The availability of results from the bubble/droplet scale using the current simulations should help advance new closure relations for the average or large-scale flows toward a multiscale model.

Similar content being viewed by others

References

C.T. Crowe, J.D. Schwarzkopf, M. Sommerfeld and Y. Tsuji, Multiphase Flows with Droplets and Particles (CRC Press, Boca Raton, 2012), pp 4–20.

M.A. Rhamdhani, K.S. Coley and G.A. Brooks, Metall. Mater. Trans. B 36, 591. (2005).

M.A. Rhamdhani, G.A. Brooks and K.S. Coley, Metall. Mater. Trans. B 37, 1087. (2006).

D. Mazumdar and J.W. Evans, Modelling of Steelmaking Process (CRC Press, Boca Raton, 2009), pp 12–60.

N. Dogan, G. Brooks and M.A. Rhamdhani, ISIJ Inter. 49, 24. (2009).

M.A. Rhamdhani, K.S. Coley and G.A. Brooks, Metall. Mater. Trans. B 36, 219. (2005).

J.E. Olsen and Q.G. Reynolds, Metall. Mater. Trans. B 51, 1750. (2020).

M.M Li, Q, Li, S.B. Kuang and Z.S Zou, Ind. Eng. Chem. Res. 55, 3630 (2016).

Q. Li, M.M. Li, S.B. Kuang and Z.S. Zou, Metall. Mater. Trans. B 46, 1494. (2015).

Q. Li, M.M. Li, S.B. Kuang and Z.S. Zou, JOM 68, 3126. (2018).

M.M. Li, Q. Li, Z.S. Zou and B.K. Li, JOM 71, 729. (2019).

G. Venturini and M. Goldschmit, Metall. Mater. Trans. B 38, 461. (2007).

B.K. Li, H.B. Yin, C.Q. Zhou and F. Tsukihashi, ISIJ Int. 48, 1704. (2008).

F.P. Maldonado, M.A. Ramirez, A. Conejo and C. Gonzalez, ISIJ Int. 51, 1110. (2011).

W.T. Lou and M. Zhu, Metall. Mater. Trans. B 44, 1251. (2013).

W.T. Lou and M. Zhu, Metall. Mater. Trans. B 54, 9. (2014).

V. De Felice, I.L.A. Daoud, B. Dussoubs, A. Jardy and J.P. Bellot, ISIJ Int. 52, 1273. (2012).

J.P. Bellot, V. De Felice, B. Dussoubs, A. Jardy and S. Hans, Metall. Mater. Trans. B 45, 13. (2014).

L. Jonsson and P. Jönsson, ISIJ Int. 36, 1127. (1996).

L.M. Li, Z.Q. Liu, B.K. Li, H. Matsuura and F. Tsukihashi, ISIJ Int. 55, 1337. (2015).

L. Jonsson, D. Sichen and P. Jönsson, ISIJ Int. 38, 260. (1998).

Y. Sheng and G.A. Irons, Metall. Mater. Trans. B 24, 695. (1993).

D. Mazumdar and R.I.L. Guthrie, ISIJ Int. 34, 384. (1994).

H.P. Liu, Z.Y. Qi and M.G. Xu, Steel Res. Int. 82, 440. (2011).

Q. Cao and L. Nastac, Metall. Mater. Trans. B 49, 1388. (2018).

R. Singh, D. Mazumdar and A.K. Ray, ISIJ Int. 48, 1033. (2008).

L.M. Li, Z.Q. Liu, M.X. Cao and B.K. Li, JOM 67, 1459. (2015).

L.M. Li, B.K. Li and Z.Q. Liu, ISIJ Int. 57, 1. (2017).

Q. Li and P.C. Pistorius, Metall. Mater. Trans. B. https://doi.org/10.1007/s11663-021-02121-w (2021).

L.F. Zhang and S. Taniguchi, Int. Mater. Rev. 45, 59. (2000).

Q. Cao and L. Nastac, Ironmaking Steelmaking 45, 984. (2018).

Q. Cao, A. Pitts and L. Nastac, Ironmaking Steelmaking 45, 280. (2018).

S. Cloete, J.E. Olsen and P. Skjetne, Appl. Ocean Res. 31, 220. (2009).

S. Cloete, J.J. Eksteen and S.M. Bradshaw, Mineral Eng. 46, 16. (2013).

Y. Liu, M. Ersson, H.P. Liu, P. Jonsson and Y. Gan, Steel Res. Int. 90, 1. (2019).

V.T. Mantripragada and S. Sarkar, Canadian Metal. Quart. 59, 159. (2020).

E.K. Ramasetti, V.V. Visuri, P. Sulasalmi, R. Mattila and T. Fabritius, Steel Res. Int. 90, 1800365. (2019).

E.K. Ramasetti, V.V. Visuri, P. Sulasalmi, T. Palovaara, A.K. Kumar Gupta and T. Fabritius, Steel Res. Int., 90, 1900088 (2019).

B.H. Zhu, B. Zhang and K. Chattopadhyay, Metall. Trans. B 51, 898. (2020).

Y. Liu, M. Ersson, H. Liu, P.G. Jonsson and Y. Gan, Metall. Trans. B 50, 555. (2019).

R.D. Morales, F.A. Calderón-Hurtado and K. Chattopadhyay, Metall. Trans. B 51, 628. (2020).

R.D. Morales, F.A. Calderón-Hurtado and K. Chattopadhyay, ISIJ Inter. 59, 1224. (2019).

C.W. Hirt and B.D. Nichols, J. Comp. Phys. 39, 201. (1981).

J.U. Brackbill, D.B. Kothe and C. Zemach, J. Comp. Phys. 100, 335. (1992).

O. Ubbink and R.I. Isssa, J. Comp. Phys. 153, 26. (1999).

Rusche, H. Computational Fluid Dynamics of Dispersed Two-Phase Flows at High Phase Fractions. (Ph.D. Thesis, Imperial College London, London, UK, 2002), pp. 115-120.

J. Smagorinsky, Month. Weather Rev. 91, 99. (1963).

M. Germano, U. Piomelli, P. Moin and W.H. Cabot, Phys. Fluids 3, 1760. (1991).

B. Niceno, M.T. Dhotre and N.G. Deen, Chem. Eng. Journal 63, 3923. (2008).

G. Agbaglah, S. Delaux, D. Fuster, J. Hoepffner, C. Josserand, S. Popinet, P. Raya, R. Scardovelli and S. Zaleski, C.R. Mec. 339, 194. (2011).

N. Ahmad, M.N. Farooqi and D. Unat, Sci. Program. 2018, 1. (2018).

P.E. Anagbo, J.K. Brimacombe and A.H. Castillejos, Canadian Metal. Quart. 28, 323. (1989).

D. Laupsien, A. Cockx and A. Line, Chem. Eng. Tech. 40, 1484. (2017).

Acknowledgements

Qiang Li acknowledges the financial support from the National Natural Science Foundation of China under Grant No. 52074079, the Fundamental Research Funds of the Central Universities of China under Grant No. N2125018, and the China Scholarship Council (No. 201706085028) as a visiting scholar in Carnegie Mellon University, USA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Additionally, on behalf of all authors, the corresponding author states no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Q., Pistorius, P.C. Toward Multiscale Model Development for Multiphase Flow: Direct Numerical Simulation of Dispersed Phases and Multiscale Interfaces in a Gas-Stirred Ladle. JOM 73, 2888–2899 (2021). https://doi.org/10.1007/s11837-021-04806-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04806-8