Abstract

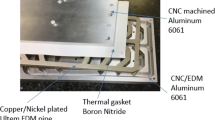

Thermal management is an important issue in electronic packaging due to the increasing complexity, miniaturization, and high density of components in modern devices. In high-power-dissipation packages, heat sinks are essential for preventing thermal damage to heat-sensitive components on the silicon chip. However, commonly used heat-sink materials (e.g., copper and aluminum alloys) have a much higher coefficient of thermal expansion (CTE) than silicon. CTE mismatch between the various materials in an electronic package can lead to stresses that can trigger complex failure mechanisms like component distortion, stress rupture, thermomechanical fatigue, and creep, thereby seriously degrading device reliability and lifetime. Therefore, it is highly desirable to minimize the CTE mismatch by developing new heat-sink materials having CTEs that are close to the CTE of silicon. In this work, low-thermal-expansion copper composites with CTEs as low as 4 ppm/°C have been fabricated by employing a negative thermal-expansion alloy—equiatomic Ni-Ti, which has a CTE of approximately −21 ppm/°C. The use of negative CTE elements, especially those with very large negative CTE values, offers an attractive route for controlling the thermal-expansion behavior of various metallic and nonmetallic materials.

Similar content being viewed by others

References

James F. Shackelford, ed., CRC Materials Sci. and Eng. Hbk., 2nd ed. (Boca Raton, FL: CRC Press, 1992).

K.A. Schmidt and C. Zweben, Section 10, Electronic Materials Handbook, Vol. 1: Packaging (Metals Park, OH: ASM, 1989), p. 1117.

C.D. Cottle et al., JOM, 50 (6) (1998), p. 67.

S. Vaynman et al., Proc. NEPCON West ’96 (Anaheim, California, 1996), p. 1711.

C. Martinek and F.A. Hummel, J. Am. Ceram. Soc., 51 (1968), p. 227; T.A. Mary et al., Science, 272 (1996), p. 90.

G.R. Kowach et al. (unpublished).

D. Taylor, J. British Ceram. Trans, 83 (1984), p. 5.

H. Mavoori and S. Jin (to be published).

S. Jin, H. Mavoori, and T.H. Tiefel (to be published).

C.M. Wayman, J. Metals 32 (6) (1980), p. 129.

T.B. Massalski, ed., Binary Alloy Phase Diagrams, 2nd ed. (Metals Park, OH: ASM, 1991), p. 2874.

Author information

Authors and Affiliations

Additional information

H. Mavoori earned his Ph.D. in materials science and engineering from Northwestern University in 1996. He is a post-doctoral member of the technical staff of the Applied Materials and Metallurgy Research Group at Bell Laboratories, Lucent Technologies. Dr. Mavoori is also a member of TMS.

S. Jin earned his Ph.D. in materials science at the University of California at Berkeley in 1974. He is currently technical manager at Bell Laboratories, Lucent Technologies. Dr. Jin is also a member of TMS.

Author’s Note: Unless otherwise indicated, compositions are in weight percent.

Rights and permissions

About this article

Cite this article

Jin, S., Mavoori, H. Low-thermal-expansion copper composites via negative CTE metallic elements. JOM 50, 70–72 (1998). https://doi.org/10.1007/s11837-998-0133-9

Issue Date:

DOI: https://doi.org/10.1007/s11837-998-0133-9