Abstract

Fabrication of Micro-Electro-Mechanical-Systems (MEMS) requires deposition of films such as SiO2, Si3N4, ZnO, polysilicon, phosphosilicate glass (PSG), Al, Cr-Au, Pt, etc. for use as structural, sacrificial, piezoelectric and conducting material. Deposition of these materials at low temperature is desirable for fabricating sensors/actuators on temperature-sensitive substrates and also for integrating MEMS structures on silicon in post-CMOS processing procedures. Plasma enhanced chemical vapour deposition (PECVD) and sputtering are amongst potential techniques for preparing films for MEMS fabrication at comparatively low temperatures. The sputtering technique has an added advantage that the process is carried out in an inert ambient (argon) and chemically sensitive substrate/sacrificial layers can be used in realization of MEMS. Furthermore, the same system can be used for depositing dielectric, piezoelectric and conducting materials as per requirement in the fabrication sequence. This enables rapid low-cost prototyping of MEMS with minimum fabrication facilities.

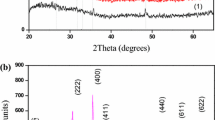

In the present work, we report preparation, characterization and application of RF sputtered SiO2, Si3N4 and ZnO films for MEMS fabrication. The effect of RF power, sputtering pressure and target-to-substrate spacing was investigated on the structural and other properties of the films. The residual stress in the films was obtained usingwafer curvature measurement technique. The deposition parameters are optimized to obtain low stress films of SiO2 and Si3N4. The self-heating of the substrate during deposition was advantageously exploited to obtain highly c-axis oriented films of ZnO without any external heating. A variety of MEMS structures such as cantilever beams, micro-bridges, diaphragms, etc. are demonstrated using bulk, surface and surface-bulk micromachining techniques.

Similar content being viewed by others

References

Beadle W E, Tsai J C C, Plummer R D 1985 Quick reference manual for silicon integrated circuit technology. (John Weiley & Sons Inc.) 5–8

Bhatt V, Pal P, Chandra S 2005 Feasibility study of RF sputtered ZnO film for surface micromachining. Surface and Coatings Technology 198: 304–308

Bhatt V, Chandra S 2007a Silicon dioxide films by RF sputtering for microelectronic and MEMS applications. J. Micromech. Microeng. 17: 1066–77

Bhatt V, Chandra S, Kumar S, Rauthan C M S, Dixit PN 2007b Stress evaluation of RF sputtered silicon dioxide films for MEMS. Indian J. Pure and Appl. Phy. 45: 377–381

Bhatt V, Chandra S 2007c Planar microstructures using modified surface micromachining process. Sensor Lett. 5: 387–391

Chu S Y, Water W, Liaw J T 2003 Influence of post deposition annealing on the properties of ZnO film prepared by RF magnetron sputtering. Euro. Ceram. Soc. 23: 1593–98

Folta J A, Hunt C E, Farrens S N 1994 Low-temperature wafer bonding of surfaces using a reactive sputtered oxide. J. Electrochem. Soc. 141: 2157–2160

Hurley R E and Gamble H S 2003 Thin film sputtered silicon for silicon wafer bonding applications. Vacuum 70: 131–140

Lu YM, Hwang WS, Liu WY, Yang J S 2001 Effect of RF power on optical and electrical properties of ZnO thin film by magnetron sputtering. Mater. Chem. Phys. 72: 269–272

Maissel L I, Glang R 1970 Handbook of Thin Film Technology, (New York: McGraw-Hill Book Company)

Mitsuyu T, Ono S, Wasa K 1980 Structures and saw properties of RF-sputtered single-crystal films of ZnO on sapphire. J. Appl. Phys. 51: 2464–2470

Ondo-Ndong R, Pascal-Delannoy F, Boyer A, Giani A, Foucaran A 2003 Structural properties of zinc oxide thin films prepared by RF magnetron sputtering. Mater. Sci. Eng. B97: 68–73

Seidel H, Csepregi L, Heuberger A, Baumgartel H 1990 Anisotropic etching of crystalline silicon in alkaline solution. J. Electrochem. Soc. 137: 3612–3626

Singh R, Kumar M, Chandra S 2007 Growth and characterization of high resistivity c-axis oriented ZnO films on different substrates by RF magnetron sputtering for MEMS applications J. Mat. Sci. 42: 4675–4683

Thornton J A 1978 Substrate heating in cylindrical magnetron sputtering sources. Thin Solid Films 54: 23–31

Xian-Ping W U, Quing-Hai W U, Wen H K 1986 A study on deep etching of silicon using ethylenediamine-pyrocatechol-water. Sensors and Actuators 9: 333–343

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chandra, S., Bhatt, V. & Singh, R. RF sputtering: A viable tool for MEMS fabrication. Sadhana 34, 543–556 (2009). https://doi.org/10.1007/s12046-009-0032-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-009-0032-y