Abstract

Whey is a by-product of cheese, casein, and yogurt manufacture. It contains a mixture of proteins that need to be isolated and purified to fully exploit their nutritional and functional characteristics. Protein-enriched fractions and highly purified proteins derived from whey have led to the production of valuable ingredients for many important food and pharmaceutical applications. This article provides a review on the separation principles behind both the commercial and emerging techniques used for whey protein fractionation, as well as the efficacy and limitations of these techniques in isolating and purifying individual whey proteins. The fractionation of whey proteins has mainly been achieved at commercial scale using membrane filtration, resin-based chromatography, and the integration of multiple technologies (e.g., precipitation, membrane filtration, and chromatography). Electromembrane separation and membrane chromatography are two main emerging techniques that have been developed substantially in recent years. Other new techniques such as aqueous two-phase separation and magnetic fishing are also discussed, but only a limited number of studies have reported their application in whey protein fractionation. This review offers useful insights into research directions and technology screening for academic researchers and dairy processors for the production of whey protein fractions with desired nutritional and functional properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Whey is the main by-product of cheese, yogurt, and casein manufacture [1]. Whey contains ~ 50% of milk solids and 20% of total proteins from milk; it is also a source of lactose, whey protein, vitamins, and dairy minerals [2]. Different types of whey are generated depending on the methods used to precipitate casein. Sweet whey, which is the most common, results from the precipitation of casein with rennet at pH 6.5 during the production of semi-hard and hard cheeses, whereas acid whey is a by-product of cream cheese, quark, paneer, and Greek yogurt manufacture, where casein is precipitated with lactic acid or mineral acids at ~ pH 4.6. In general, greater than 70% of the total dry matter in whey is lactose, while 7.5–14% of the dry matter is proteins [3]. Whey protein mainly consists of β-lactoglobulin (BLG), α-lactalbumin (ALA), and glycomacropeptide (GMP, present in renneted whey only, obtained from casein during the first enzymatic step in cheese processing), as well as a number of minor protein/peptide components such as immunoglobulins (Igs), bovine serum albumin (BSA), lactoferrin (LF), lactoperoxidase (LP), and proteose-peptone (Table 1).

Whey was treated as a waste for much of the twentieth century and used as animal feed or discharged to trade waste and/or onto fields [9]. However, the high organic load (biological oxygen demand (BOD): > 35,000 ppm, chemical oxygen demand (COD): 60,000 ppm [10]), mainly coming from the lactose and proteins present in whey, has led to increasingly strict environmental regulations, which limit the disposal of untreated whey. Global whey production is estimated to be greater than 200 million tonnes per annum [10]. To minimize the environmental impact of whey disposal and maximize by-product valorization, most constituents in whey can now be recovered and converted into high value products.

Whey utilization processes have evolved into three routes [11]:

-

1.

Direct conversion of whey

-

2.

Biological and chemical conversion to electricity, biogas, or biochemicals, and

-

3.

Fractionation of components to recover value added products

Direct conversion is perhaps the simplest route. Products include whey cheese (e.g., Ricotta) or whey beverages, although the market size is currently limited for these products. A further, more common route is the concentration and drying of whey solids to make whey powder. The removal of salts from whey using nanofiltration (up to 40% mineral removal), electrodialysis (up to 70% mineral removal), and ion exchange (up to 90% mineral removal) can add further value, leading to the production of demineralized whey powders (i.e., D40, D70, and D90).

The organic content of whey can be used to generate electricity, for example, in microbial fuel cells [12], or to produce biogas such as methane via anaerobic digestion [13]. Biochemicals such as ethanol and lactic acid can also be produced by fermentation, while lactosyl urea and ammonium lactate can be produced by reacting lactose with urea and ammonia, respectively [14, 15].

The fractionation of the principal components of whey into value added products makes use of the intrinsic value of whey constituents including lactose, proteins, and dairy minerals. The process for lactose separation from whey is well developed, where ultrafiltration and nanofiltration are used to produce a concentrated lactose solution after which evaporation, crystallization, and drying are employed for lactose powder production. As lactose permeates through the membrane processes, whey proteins that are retained by the ultrafiltration membrane are commonly recovered and concentrated at the same time to produce whey protein concentrate (WPC, containing up to 80% protein by weight) and whey protein isolate (WPI, containing up to 90% of protein by weight).

Whey proteins are arguably the most valuable food protein available, as they are a rich source of all essential amino acids that are integral to human health [14, 16]. Whey proteins have unique functional and nutraceutical characteristics (Table 2), making enrichment of these proteins in whey powder and the isolation and purification of individual whey proteins commercially appealing. This potential for value adding has promoted the development and adoption of separation technologies in dairy processing over the last couple of decades (Fig. 1), enabling the separation of target whey proteins from various starting materials including skim milk, whey, and bovine colostrum.

Schematic indication of the increasing value of whey powder, whey protein concentrate, and whey protein fractions since the 1960s. Reproduced under a Creative Commons license from [34]

To the best of our knowledge, there are very few review articles published to date discussing whey protein fractionation, except for those focused on (i) biotransformation of whey into bioprotein and bioactive peptides [35], (ii) membrane processes [3, 16], and (iii) techniques in fractionating α-lactalbumin and/or β-lactoglobulin [2, 36, 37]. Therefore, we aim to provide a comprehensive review on the fractionation of the main proteins in whey, covering the separation principles of the latest isolation and purification techniques, and the yield and purity of individual proteins obtained from these processes. While our focus is the enrichment and fractionation of individual proteins from whey and its derivatives (e.g., WPC and WPI), isolation and purification of these proteins from other sources in dairy processing (e.g., skim milk and bovine colostrum) are also included where relevant.

Principles of Separation

The principles that underpin the selective separation of one whey protein from another are largely based on differences in physical and chemical properties such as charge, size, and solubility. These can be the native properties exhibited in dairy systems or altered properties resulting from the manipulation of environmental conditions, including pH, temperature, and ionic environment such as the conductivity and presence of other ions (Fig. 2). Single or multiple protein properties may be manipulated to realize protein fractionation in various techniques. The effect of charge, size, and solubility in response to the manipulation of these environmental conditions and the manipulation of these properties is discussed here in turn.

Charge

Proteins carry a net positive or negative charge when the solution pH is below or above their isoelectric point (pI), which is determined by the pK values of the ionizable polar groups in the side chains. Altering the net charge of whey proteins in a mixture is commonly used in ion exchange chromatography to separate proteins carrying different net charge through careful selection of cation or anion exchangers. The net charge of proteins can also be used to improve membrane performance, as negatively charged proteins can be strongly rejected by a negatively charged membrane. Isolation of individual whey proteins is impossible if based purely on their pIs, because the isoelectric points of whey proteins overlap with one another (Table 1). In general, they fall into two ranges (i.e., 4.3–8.3 for BLG, ALA, and BSA and 7.0–9.5 for LF and LP). This makes rapid isolation of LF and LP from the other proteins possible using ion exchange chromatographic systems [38,39,40], but further separation is required to harvest pure LF and LP. The range of pI of the Igs is wide, as bovine immunoglobulins comprise IgG (with two subclasses: IgG1 and IgG2), IgA, and IgM.

It is worth noting that the isoelectric point of a whey protein can change with ionic strength or the composition of the solution in which the protein is solubilised. The pI of lactoferrin, for example, changes from 8.4 in water to 5.2 in a simulated milk ultrafiltrate (SMUF) buffer [41]. As the composition of whey is close to that of SMUF, the actual pI of lactoferrin in whey may be around 5 rather than 8.4 as measured in water. This discrepancy may be applicable to other whey proteins (e.g., pI = 6.2 for BSA in SMUF vs. 4.7–5.1 reported in the literature (Table 1)) [41]. The net charge of LF was found to change from positive to negative when the ionic strength of the solution exceeded 30 mM [42] due to the formation of aggregates (see the “Size” section). The dilution of an SMUF buffer by greater than 100-fold, on the other hand, showed that the net charge of LF changed from negative to positive [41].

Size

Similarly, based on their molecular weight, whey proteins can be roughly grouped into smaller proteins (i.e., less than 50 kDa: BLG and ALA) and larger proteins (i.e., 50–150 kDa: BSA, LF, LP, and Igs). A charged protein is known to be surrounded by an electrical double layer (i.e., a diffuse ion cloud). as characterized by the Debye length (\({L}_{D}\) in nm):

where \(I\) is the solution ionic strength (in mol/L). Since the thickness of this diffuse double layer in aqueous systems is more pronounced at low ionic strength, the effective hydrodynamic volume of the charged protein molecule becomes larger. This property is important to size-exclusive chromatography and ultrafiltration, as both principally separate proteins based on size [43]. Highly selective separation of individual proteins, however, cannot be obtained without making the target whey proteins distinctively larger or smaller than other proteins present in the whey preparation.

Self-association of proteins leads to the formation of small aggregates such as dimers and oligomers (e.g., trimers and tetramers), increasing the size of protein molecules. BLG is mainly a monomer at pH below 3.5 and above 7.5 but self-associates between pH 3.5 and 5.5. Hence, BLG is generally present as a dimer in sweet whey (at pH 5.6), exhibiting an MW of ~ 36 kDa rather than 18.4 kDa as a monomer (Table 1). The oligomerization of whey proteins has also been reported to be induced by changes in ionic strength and solution composition. For example, the formation of lactoferrin micelles or aggregates 110 nm in size was observed in a 100-mM salt solution [42]. Tetramers of lactoferrin (MW ~ 300 kDa) were detected in a 0.2-M borate buffer (pH 7.4) with 20 mM calcium chloride [44]. Lactoferrin was also found to aggregate in SMUF buffer (without Ca2+ and Mg2+) and even when this SMUF buffer was diluted eightfold [41]. While whey protein oligomers can remain soluble in solution, the aggregation induced by thermal treatment and other methods, as discussed in the next section, may lead to the formation of insoluble particles, where solid–liquid separation is required to harvest the target protein(s).

In contrast, the size of whey proteins can be reduced by hydrolysis with proteases such as trypsin and pepsin. Unlike caseins, which are highly digestible by enzymes, hydrolysis of whey proteins is much slower and often requires heating to enable protein unfolding and enzymatic action; the susceptibility to enzymes also differs due to differences in sequence and structure. ALA, for example, can only be slowly hydrolyzed by trypsin but can be rapidly hydrolyzed by pepsin. In contrast, BLG can be broken down more rapidly by trypsin than pepsin. The molecular weight of their hydrolysates ranges from < 500 Da to ~ 8 kDa, with the majority being 3–4 kDa [45]. When heated at 90 to 100 °C for 5 to 10 min, structural or conformational changes to native BLG were shown to improve its proteolysis by trypsin [46].

Enzyme hydrolysis can be used to create large differences in molecular size facilitating isolation when one protein is selectively digested. It was reported that tryptic digestion of BLG (at pH 7.7, 42 °C) in sweet whey UF permeate enabled a purified fraction of native ALA (90–95%) to be recovered using a 10 kDa UF membrane [47]. Pepsin hydrolysis of BLG (at pH 3, 37 °C), coupled with ultrafiltration (10 kDa MWCO), was found to reduce the BLG antigenicity in WPC [48]. More recently, two commercially available, food-grade fungal proteases (fungal protease 31,000 and fungal protease 60,000), were used to hydrolyze whey proteins in casein whey [49]. After incubation at pH 4 and 45 °C for 5 h, BLG remained intact, resulting in a selectively enriched high concentration BLG fraction, which could be recovered by ultrafiltration (10 kDa MWCO). The fact that BLG aggregates into dimers or oligomers at intermediate pH (i.e., around pH 4) was believed to prevent proteolysis, allowing for selective isolation.

Solubility

Whey proteins are generally soluble in the original serum. They are, however, sensitive to aggregation and denaturation, which can be triggered by changes to the solution environment, such as temperature, pH, ionic strength, and composition. The formation of aggregates larger than 10-mer oligomers makes whey proteins insoluble, often forming aggregates > 1 µm in diameter. These insoluble aggregates precipitate and can be separated using solid–liquid separation processes such as centrifugation and membrane filtration.

Temperature

Temperatures greater than 65 °C are known to have a direct effect on the conformation of polypeptide chains in whey proteins, leading to their unfolding (i.e., denaturation) and subsequent irreversible association [50]. Hydrophobic moieties (e.g., the sulfhydryl groups) that are initially buried in the interior of these protein molecules are exposed upon heating at a pH close to their pI or in the presence of salts. This allows for hydrophobic interactions to occur, leading to protein aggregation and oligomer and soluble aggregate formation [51, 52]. These soluble aggregates further interact and self-assemble into particulate aggregates upon prolonged heating, as the electrostatic repulsions become too low to stabilize these aggregates in a solution [53]. Precipitation of whey proteins can occur when whey is heated in acidic conditions (pH 3.5–5.5) at above 90 °C for 10 min [35]. Upon heating, it was reported that Igs in whey are denatured first, followed by BSA, BLG, and ALA [54]. Although the denaturation temperature of ALA is lower than BLG (Table 1), ALA appears to be the most heat resistant whey protein fraction, and its denaturation is highly reversible compared to other proteins [55].

Aggregation is known to be influenced by initial protein concentration. The size of BLG aggregates was shown to increase with increasing initial concentration at 65 °C over the concentration range of 0.1–1% [56]. It was also demonstrated to be related to the square root of the initial concentration, at 65 °C or slightly higher temperatures and at a pH of 6.75–6.95 [57]. The rate of aggregation was found to be proportional to the BLG monomer concentration [58]. When less than 10% of the BLG present in the solution was native, the aggregation process slowed down rapidly and even ceased [59].

While thermal aggregation and denaturation can be an effective approach to fractionate proteins, they could influence the subsequent functionality of isolated whey proteins. For example, changes in sedimentation and gelation [60], increases in turbidity [61], and fouling of heat exchangers [62] were reported when whey protein solutions (> 3.5%) were heated to 75 °C and above due to the denaturation and unfavorable aggregation of proteins.

pH

Changing the solution pH may alter the nature and distribution of the net charge of a protein, which in turn determines electrostatic interactions between proteins. Solubility increases in acidic or alkaline solutions because of the electrostatic repulsion among protein molecules that exhibit an excess number of charges of the same sign. Protein unfolding can occur at extreme high or low values of pH, leading to the exposure of more hydrophobic groups. For example, BLG dimers tend to denature when the solution pH was adjusted to greater than 8.0 [63]. At pH 8.0, the reactivity of the thiol group in BLG is higher, making it readily available for polymerization via thiol/disulfide exchange. Heating is required, however, to unfold the protein chains for this to occur at pH 7.0 [64, 65].

In general, a protein is least soluble at its isoelectric point, where protein–protein interactions are favored, leading to the formation of disulfide bonds, because the electrostatic forces among the molecules are at a minimum and have the fewest number of interactions with water molecules [35]. It was reported, however, that the lowest protein solubility in a whey protein isolate solution (12 g/L, 40–60 °C) occurs at pH 4.5 rather than 5.2, the pI of the most abundant protein BLG [66]. As seen in Fig. 3, the measured whey protein solubility could not be directly correlated to the change of pH from either side of pH 4.5. Although the solubility of individual whey proteins was not identified, these results indicate that solubility in such a protein mixture is a reflection of the collective aggregation of all whey proteins whose properties (e.g., conformation, size, net charge, and reactivity of side groups) are influenced by the solution pH. Selective precipitation of whey proteins, therefore, is typically achieved by choosing the optimal solution pH and the temperature at which precipitation of target proteins takes place. ALA, for example, can be precipitated from a whey protein isolate solution at pH 4.3 and 50 °C to enable its separation from BLG using membrane filtration processes [67].

Effect of pH and temperature on protein solubility in a whey isolate solution (12 g/L). Reproduced with permission from [66]

Other Environmental Conditions

It is a well-known approach to precipitate proteins by using an extraneous agent that can lower protein solubility. Such precipitants can be salts, organic solvents, or long-chain polymers. In dairy processing, salt-based precipitants are more commonly used due to regulatory limitations and the simplicity of downstream processing. Ions dissociated from salts, such as monosodium phosphate (NaH2PO4) and sodium chloride (NaCl), can reduce water activity by binding tightly to water molecules making fewer available to form hydrogen bonds with the hydrophilic amino acids in protein molecules [68, 69]. In turn, the hydrophobic interactions between proteins become stronger than the hydrophilic interactions between water and proteins. This leads protein molecules to self-associate and eventually precipitate, a process known as salting out.

Aggregation is another route to potentially isolate and separate whey proteins. BSA molecules self-assemble into small aggregates at low ionic strength [70]. In contrast, LF exists as monomers at very low ionic strength but forms small aggregates at ionic strength higher than 10 mM [42]. At an acidic pH (2–3), aggregation of BLG is unlikely to occur because BLG molecules are positively charged and the thiol groups are stable, resulting in repulsive electrostatic interactions between monomers. Such interactions, however, can be reduced through the screening of charged groups by increasing the ionic strength. The addition of salt can increase the rate of protein unfolding, leading to an increase in aggregation rate and protein denaturation temperature [71].

Further, the denaturation process of a particular whey protein can be affected by the concentration of divalent ions such as calcium. An increase in calcium concentration can decrease the charge of a protein, as calcium binds to negatively charged amino acids. This reduces the repulsive forces between protein molecules, promoting the formation of aggregates [72, 73]. For example, ALA is a strong calcium-binding protein due to the presence of a binding site formed by four aspartate residues. When the pH is below 5, the ability of ALA to bind calcium decreases, as these aspartate residues are partially pronated [74]. The apo form of ALA (i.e., Ca-free form) is therefore highly heat sensitive and can denature at around 30 °C (Table 1). These properties can be used to separate ALA from other whey proteins. After calcium is removed by ion exchange resins, with further reduction of pH (to 4.3–4.8), ALA can be denatured and flocculated from whey to obtain a BLG-rich fraction [75].

BLG and ALA can be destabilized by different or common conditions. The level of denaturation of BLG and solution viscosity both increased when a whey protein isolate solution (8 wt%) was heated to 85 °C with the addition of 2.2 mM (0.088 g/L) of calcium. This is because the number of accessible sulfhydryl groups in BLG doubled compared to no calcium addition [76]. In contrast, the denaturation of ALA was not influenced by the addition of calcium, because no free sulfhydryl groups were present. Irreversible denaturation of ALA only occurs when heated above 90 °C in the presence of calcium [77,78,79]. Further increasing calcium concentrations in a WPC solution from 0.01 to 1 g/L, however, could destabilize both ALA and BLG, with the denaturation rate being the highest between 0.3 and 0.8 g/L calcium over a range of pH values (6.2 to 8.2) [80].

Precipitation can also be triggered by the addition of complexing agents. Complexation of BLG in acid whey, for example, occurs in the presence of reagents such as chitosan through electrostatic interactions [81]. Once separated by centrifugation, chitosan can be removed by acid hydrolysis to obtain a fraction of native BLG (95% purity). Carbonate and bicarbonate ions, as well as metal ions, were also used in a recent patent to form complexes with BLG, so that the ALA-rich fraction could be separated from a WPI solution [82]. The addition of external reagents, however, may not be a preferred approach due to strict regulatory requirements in food processing.

In general, thermal precipitation and the use of ions to induce salting out are common laboratory scale methods reported in the literature to separate ALA or BLG from other whey proteins, in combination with either centrifugation or filtration, probably because these proteins are the most abundant in whey [37]. While these separation techniques result in proteins of high purity, measured by the purification factor (see Fig. 4), they are not widely adopted on a commercial scale in dairy processing, as multiple unit operations are required to precipitate, resolubilize, and purify the target proteins [36]. The technologies available to fractionate whey proteins on a commercial scale are discussed in the following sections.

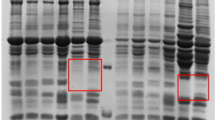

Typical range of purification factor (PR) for common techniques used in whey protein fractionation [132]. Purification factor is defined as the ratio of target protein concentration (as a fraction of total protein) after and before a purification step

Fractionation Technologies

To fractionate whey proteins on a commercial scale, separation processes need to be simple, rapid, and non-denaturing, producing high quality products with high yield and purity. This review focuses on the two groups of fractionation technologies that have been developed in the past few decades to meet these criteria: membrane separation and resin-based chromatography.

An overview of the studies completed using these approaches is provided in Table 3, while the reported purities of the target proteins is presented in Fig. 5. These techniques are then explored in the following sections.

Reported purity of target proteins from the selected studies summarized in Table 3 for common fractionation techniques discussed in this review

Membrane Separation

Membrane Filtration

Membrane filtration processes have been used in a wide range of dairy manufacturing processes, ranging from on-farm raw milk concentration, milk standardization, and whey processing to effluent treatment [84]. Acting as a permeable barrier, filtration membranes separate the constituents in milk and whey (i.e., fat, caseins, whey proteins, lactose, and minerals) based on their size, concentration, or electrical charge. Industrial membrane processes employed for whey processing are typically pressure-driven crossflow filtration systems, where whey passes tangentially over the membrane surface. This divides the inlet stream into a permeate stream that contains components that pass through the membrane and a retentate stream that contains the fraction that is rejected by the membrane.

Microfiltration is typically used as a pre-treatment step to remove bacteria and fat (> 100 nm in particle/solute size) prior to the concentration of whey proteins using ultrafiltration. Ultrafiltration membranes with a molecular weight cut-off (MWCO) of 10 or 20 kDa are typically used to separate whey proteins from lactose and minerals, given that the smallest whey protein (i.e., ALA) has a molecular weight of 14 kDa (Table 1). The retentate, which contains all whey proteins (at least 35% on a dry basis), is often used as the starting material for the fractionation and isolation of specific whey proteins using membrane filtration or chromatographic systems. The protein content can be enhanced to 80% if diafiltration is implemented. During diafiltration, water is continuously added to the feed so that lactose and minerals are permeated simultaneously through the membrane, hence effectively enhancing the protein purity in the retentate.

Ultrafiltration membranes with MWCOs between 10 and 300 kDa have been investigated for the fractionation of whey proteins. Regenerated cellulose (RC), polyethersulfone (PES), and polyvinylidene fluoride (PVDF) membranes exhibit low protein binding characteristics and are commonly used for processing protein solutions [85]. Among these, PES membranes are the most widely adopted UF membrane in dairy processing owing to their low cost and good thermal and mechanical stability [3]. In industrial operations, polymeric spiral wound membrane elements are often used to facilitate turbulent flow and thus to reduce boundary layer effects and mitigate membrane fouling [86].

The transmission of a protein can be quantified in terms of the sieving coefficient (\(S\)):

where \(Rej\) is the rejection coefficient of a protein and is a function of the feed concentration (\({C}_{F}\)) and the permeate concentration (\({C}_{P}\)):

Therefore, the sieving coefficient can also be calculated by

The membrane selectivity (\(\varphi\)) toward protein \(i\) in a binary mixture is defined as the ratio of the sieving coefficients for protein \(i\) to protein \(j\):

The smaller and the most abundant whey proteins, ALA and BLG, are very similar in size (14 and 18 kDa respectively), making their separation difficult in a single-step membrane filtration process. Therefore, many studies have focused on optimizing operational modes (e.g., batch, continuous, and diafiltration) [87], MWCOs [88, 89]), as well as operating parameters (e.g., volume reduction ratio, VRR) [90] and transmembrane pressure (TMP) [88]) to improve the separation of these two proteins using PVDF and PES membranes. The purity of ALA achieved among these studies, however, was reported to be only between 40 and 60%, indicating that the membrane selectivity of these proteins is the limiting factor.

To enhance purity and yield, protein properties can be manipulated before membrane filtration is applied, as discussed in the “Principles of Separation” section. For example, ALA can be precipitated from WPC when heated to 50–55 °C at pH 3.4–3.9 [67, 91,92,93]. Under these conditions, ALA loses its bound calcium, unfolds, and precipitates, often together with BSA and Igs. This allows for the isolation of native BLG from whey using microfiltration and ultrafiltration membranes through diafiltration processes [93,94,95]. The precipitated ALA can be re-solubilized by pH adjustment and further purified using 10 or 20 kDa UF membranes to remove BSA and IgG. Similarly, the aggregation of BLG can be achieved through heat treatment (> 80 °C for 5 min) or pH adjustment (pH 10.7 at 7.2 °C), after which UF membranes of 100–150 kDa can be used to remove BLG from the retentate [96, 97]. Drying of the retentate produces whey protein powders with reduced BLG content, which may be useful as BLG is known to be a common food allergen for some young children. The purity of proteins obtained using these aggregation/precipitation approaches can reach up to > 91% for ALA and > 97% for BLG [67]. It is worth noting that high purity is often achieved by operating UF in a diafiltration mode.

Immunoglobulins, the comparatively large proteins in whey, can also be separated using UF membranes. Milk and whey contain a significantly lower concentration of Igs (0.15–0.8 and < 0.1 g/L, respectively) compared to cow colostrum (20–200 g/L). Studies have reported the use of diafiltration processes with a PVDF cylindrical membrane of 100 kDa and a tubular ceramic membrane of 300 kDa to obtain IgG-enriched solutions with a purity of 25 and 15% from feta cheese whey and clarified whey, respectively [98, 99]. The recovery of Igs from colostrum could be achieved using UF membranes with 100 kDa MWCO after removing blood, somatic cells, fat globules, and casein micelles by microfiltration (0.1 µm) [100].

The fractionation of the “middle molecules” in whey (i.e., BSA, LF, and LP; MW: 66 to 89 kDa) using membrane filtration systems has not been a major focus. This indicates again the limited selectivity ultrafiltration membranes can offer for molecules similar in size. Native BSA, however, has been used as a model foulant for studying protein fouling in membrane filtration systems [101,102,103,104,105].

In recent years, polymeric ultrafiltration membranes have been modified by incorporating charged functional groups on the membrane to enhance the electrostatic repulsion between the charged surface and proteins [100, 106]. PES membranes (100 kDa MWCO) were functionalized by Cowan and Richie to form an open pore structure with charged sulfonate grafted polymer chains [100]. These membranes showed a five-fold improvement in selectivity between ALA and BLG compared to the original membrane at pH 7.2 due to the stronger electrostatic repulsion between the negatively charged membrane and the negatively charged BLG and the stronger size sieving effect caused by the reduced pore size in the functionalized membrane. Arunkumar and Etzel modified regenerated cellulose membranes (300 kDa) by attaching alkyl ammonium groups, which were used to fractionate ALA and BLG from their binary mixture [107]. At optimal operating conditions (pH 4.3, 8 mS/cm conductivity), the nearly neutral ALA molecules could be separated more effectively from the positively charged BLG molecules (pI: 4.4 for ALA and 5.2 for BLG, see Table 1), resulting in a nearly five-fold enhancement in ALA selectivity compared to the uncharged membrane [107]. The fractionation of ALA and BLG from milk serum permeate produced from skim milk microfiltration (500 kDa PVDF) was also achieved, although the ALA to BLG selectivity reduced by 58% compared to that observed in the binary mixture [108]. A high purity of ALA and BLG (87 and 83%, respectively) could potentially be achieved based on their proposed three-stage process. Charge modification of a composite regenerated cellulose membrane (100 kDa) by incorporating sulfonic acid group on the membrane surface can also be used to concentrate whey proteins to enhance the rejection of negatively charged proteins. This results in at least a two-fold higher permeate flux compared to a 10-kDa uncharged membrane without compromising protein recovery [109].

Electromembrane Processes

Electrodialysis (ED) is a process designed to separate ionic species (e.g., salts and organic acids) by using charged polymer membranes, often referred to as ion exchange membranes. Ionic species are removed from the feed stream under an electrical potential driving force, as cations (e.g., K+ and Na+) migrate toward the cathode and anions (e.g., Cl−) migrate toward the anode. A commercial ED stack can contain up to 200 flow channels with the operating current and voltage being up to 185 A and 400 V, respectively [110,111,112,113]. Whey demineralization and salt removal from skim milk are the two main applications of electrodialysis in the dairy industry.

In general, ion exchange membranes are not permeable to molecules and ions greater than 500 Da [114], and so proteins and lactose are completely rejected. When they are replaced with filtration membranes in an electrodialysis system, the electrical driving force can be used to selectively migrate large charged molecules (e.g., whey proteins). Ultrafiltration membranes are often used for this purpose in an advanced electro-membrane system called electrodialysis with an ultrafiltration membrane (EDUF). On a smaller scale, this process is also referred to as electrophoretic membrane contactor [115]. As illustrated in Fig. 6, “restriction membranes” are needed to prevent these larger organic molecules from entering the electrode compartments. These restriction membranes are filtration membranes with pore size smaller than the smallest organic molecules in the feed stream [116]. The separation membrane is preferably an uncharged membrane, which can reduce water splitting under the high electrical strength applied in these systems (up to 2000 V/cm) [117,118,119].

Illustration of a typical electrodialysis with ultrafiltration (EDUF) process where an ultrafiltration membrane is used as a separation membrane. Reproduced with permission from [41]

EDUF exhibits some advantages over conventional filtration systems for whey protein separation. For example, the elimination of a pressure driving force in EDUF minimizes the formation of a highly impermeable fouling layer, which is usually deposited on the membrane surface during ultrafiltration of protein-rich solutions [120]. EDUF can potentially achieve a greater selectivity since the mobility of proteins can be manipulated by both size and charge. One key drawback for EDUF, however, is the migration of small inorganic ions and organic acids through the porous separation membrane. This may lower the purity of the product stream containing the target protein(s).

EDUF processes have been studied for the separation of immunoglobulin G from human plasma, proteins from egg white, and hemoglobin from a mixture with BSA [116, 121, 122]. In dairy processing, the focus has been the isolation of minor whey proteins such as LF and Igs from whey, given the high nutritional benefits and commercial values of these proteins. A PES UF membrane with an MWCO of 500 kDa was used by Ndiaye et al. to demonstrate the transfer of LF from an LF-enriched whey solution in an EDUF process operated at pH 3.0. The yield (only 15%) and purity were low, however, due to the simultaneous migration of other whey proteins into the product stream [123]. More recently, Wang et al. [41] fabricated a polyvinyl alcohol (PVA) separation membrane in-house for the separation of LF and Igs from whey solutions using EDUF. Due to the formation of LF tetramers in whey, both LF and Igs were largely rejected by the PVA membrane, while smaller proteins such as BSA permeated through. Adsorption of proteins within the membranes was observed, however, leading to considerable protein loss. This could be alleviated by reducing the ionic strength of the buffer. It was also found that the protein concentration in the product stream needed to be maintained at a level lower than that in the feed stream in order to avoid any back diffusion of proteins through the separation membrane. More research needs to be done to address these challenges for EDUF processes to produce high-quality whey protein fractions.

Bipolar membranes, a special type of ion exchange membrane, have been incorporated in ED systems for the acidification of milk and whey without the need to add chemicals. These membranes are composed of an anion exchange layer, a cation exchange layer, and a hydrophilic layer in between. Under an electrical field, water dissociates at the interlayer into H+ and OH− ions, allowing the H+ ions to be used for adjusting the pH of the target dairy stream (Fig. 7). This process can achieve demineralization and acidification of the feed simultaneously, hence providing a new approach to tune protein characteristics by altering the pH and ionic strength. Bazinet et al. demonstrated that this technique could precipitate greater than 90% of BLG when WPI solutions were lowered to pH 5 using bipolar membranes together with 5 to 13% of other whey proteins. This led to an optimal yield of 44% of BLG with 98% purity from 5% WPI solutions at pH 5 [124].

Configuration of a bipolar membrane electrodialysis cell for whey acidification (CEM, cation exchange membrane, AEM, anion exchange membrane; BPM: bipolar membrane). Reproduced with permission from [125]

The use of an electric field in conventional UF systems has been reported to be an effective method for fouling mitigation in protein separation, where a UF membrane is placed between two electrodes. The anode is typically located on the feed side so that negatively charged protein molecules can be dragged away from the membrane surface when an electrical field is applied during ultrafiltration. These systems are often referred to as electrically enhanced ultrafiltration (EUF). BSA solutions are commonly used in the literature for studying the effect of the electric field applied [126] and MWCO [127], but the effectiveness of EUF in fouling mitigation for processing whey solutions has yet to be proven. The use of a pulsed electric field can further reduce the energy consumption and enhance permeate flux in EUF [128, 129]. For example, a three-fold increase in permeate flux was observed when a pulsed electric field was applied during ultrafiltration of a BSA solution using a PVDF membrane (MWCO: 25 kDa), with the addition of alumina particles to the feed solution to enhance turbulence on the membrane surface [130]. The commercial application of EUF for whey protein fractionation, however, will need to overcome the difficulties in incorporating electrodes into standard commercial filtration modules without extensive modification.

Resin-Based Chromatography

Resin-based chromatography is another common technology used for whey protein isolation, often resulting in higher protein purity than can be achieved by membrane processes. Three chromatographic techniques have been widely explored for whey protein separation, including

-

1)

size exclusion chromatography, which separates based on molecular size difference,

-

2)

ion exchange chromatography, which is based on charge difference, and

-

3)

affinity chromatography, which is based on biorecognition of protein molecules.

The general theory related to chromatographic separation is described in this section, followed by an exploration of each of the three main resin-based chromatographic techniques.

In chromatography, a liquid is pumped through a bed of particles (e.g., gels or resins) packed in a column. The packed particles act as the stationary phase and interact with the target molecules in the mobile phase (i.e., the solution containing the target proteins). The stronger the interaction, the slower the transport of the molecules through the system. The degree of preference of a protein for the stationary phase is expressed by the distribution constant or partition coefficient, K:

where \({c}_{\mathrm{stat}}\) and \({c}_{\mathrm{mob}}\) are the concentration of a protein in the stationary and the mobile phase, respectively.

The retention time (\({t}_{\mathrm{R}}\)) is a key parameter to monitor in chromatographic systems, which is defined as the time taken by the target protein to travel through the column (see Fig. 8). If a molecule is not retained by the stationary phase, i.e., \(K\) = 0, its retention time is referred to as the dead time (\({t}_{0}\)). The partition ratio, also referred to as retention factor or capacity factor (\({k}^{^{\prime}}\)), can be estimated from the ratio of the net retention time (\({t}_{\mathrm{R}}^{^{\prime}}={t}_{\mathrm{R}}-{t}_{0}\)) to the dead time:

The capacity factor is also defined as the mole ratio of a protein between the stationary and the mobile phase, and is related directly to the partition coefficient (Eq. 6), provided that no overloading occurs:

where \({n}_{\mathrm{stat}}\) and \({n}_{\mathrm{mob}}\) are the number of moles of a protein in the stationary and the mobile phase, respectively, and \({V}_{\mathrm{stat}}\) and \({V}_{\mathrm{mob}}\) are the volume of the stationary and the mobile phase in the chromatography system, respectively.

To achieve a good separation, the individual proteins in a mixture must show different net retention times, meaning that they need to differ in their \({k}^{^{\prime}}\) values. The ratio of the \({k}^{^{\prime}}\) value of two proteins, therefore, defines the separation factor of relative retention (\(\alpha\)):

A separation is possible only if \(\alpha\) is greater than 1 indicating effective separation from a thermodynamic perspective. The separation efficacy of two proteins, however, is dictated by the resolution number (\({R}_{s}\)), which can be estimated by

where \(w\) is the width of the downstream concentration peak. To avoid co-elution, the optimal resolution number is 1.5 [131] so that complete separation of two proteins can be achieved.

The width of the protein concentration peak is a characteristic of the flow distribution within the column. This is often expressed in terms of the number of theoretical plates (N), which can be estimated based on the width of the peak in relation to its retention time:

The total resolution of a column is a function of the column efficacy, column selectivity, and capacity factor, which are represented by the first, second, and third terms in the following expression:

It can be seen from Eq. 13 that the resolving power of a column can be enhanced by increasing the number of theoretical plates. This parameter is related to the total length of the packed column (L) by the height of a theoretical plate (H), which is a function of the mass transfer coefficient within the column:

Thus, the resolving power can be increased by having a longer column or by reducing the plate height through increased mass transfer efficiency. The use of smaller resin beads, for example, can lead to smaller plate height and hence better chromatographic performance. In practice, however, the pressure drop across the column and the high cost of the resin beads limit the plate number to be less than 105 and the plate height to less than 0.1 mm, respectively [131].

For industrial applications, chromatography is often designed to maximize throughput and recovery rather than resolution by optimizing the linear flow rate (\(v\)) using the Peclet number, which is the ratio of the convective transport between the beads and the diffusive transport within the beads:

where \({d}_{p}\) is the average particle diameter and \(D\) is the diffusion coefficient. The Peclet number is typically set to between 3 to 10 in column design. In a large-scale operation, however, the flow rate used is often one order of magnitude larger than that determined from this relationship to maximize process efficiency, provided the purity of the target protein is adequately achieved [132].

Size Exclusion Chromatography

Gel chromatography, or size exclusion chromatography, is a common chromatographic method used for analytical purposes that separates proteins based on their molecular weight and/or hydrodynamic size [133]. Sephadex (dextran-based), sepharose (agarose-based), and sephacryl (acrylamide-based) are the three common types of matrices used in gel chromatography. Large proteins can freely pass through a column packed with the gel medium, while the passage of small proteins is delayed if they are small enough to enter and migrate through the porous gel matrix. Hence, the retention time is inversely proportional to the size of a protein molecule. Since the proteins do not bind to the gel, their biological activity can be maintained, however, the resolution is not affected by the buffer used [131, 134], limiting effective separation of whey proteins.

Whey proteins have only been separated with low resolution and low productivity using this technique. Igs have been isolated from various whey streams using Sephacryl S-300 [134] and BLG and ALA separated using Sephadex media [135, 136]. Consequently, this method is often coupled with other fractionation techniques. For example, gel filtration is often used following ion exchange and affinity chromatography (to be discussed in the next two subsections). Sephadex G-50 filtration was also to separate ALA and BSA following co-elution from an upstream anion exchange chromatography step [137].

Ion Exchange Chromatography

Ion exchange chromatography is a very common chromatographic technique used in dairy processing [138]. Whey proteins that carry an opposite charge can be adsorbed onto resin beads. Protein binding can be controlled by the pH and ionic strength of the solution, the net charge of a protein molecule, and the binding capacity of the ion exchange resins [139]. Good separation can be achieved by maintaining the buffer pH at least one pH unit below or above the pI of the target protein [140]. Common charge groups (i.e., ligands) functionalized onto ion exchanger resins include sulfopropyl (SP), carboxylethyl (CM), quaternary ammonium (QA), and diethylamineothyl (DEAE) for strong cation, weak cation, strong anion, and weak anion exchangers, respectively.

The use of cation exchange resins (CEX) to isolate LF and LP from whey or skim milk is well-established in industry based on the binding of the positively charged LF and LP molecules (at the natural pH of whey) to the negatively charged resin particles [38,39,40]. Once the cation exchange resins in the column are fully loaded with proteins, salt solutions of different concentrations are then used to elute the adsorbed LF and LP from the resin beads. Such selective elution procedures are commonly used in both anion and cation exchange chromatography. In general, less strongly bound proteins are released from the resins in the first elution, after which a salt solution of higher concentration is used to recover the more strongly bound proteins (i.e., the LF rich fraction). The eluted proteins can then be separated from the salts by ultrafiltration with diafiltration to achieve a high purity stream for powder production via evaporation and drying [14].

To improve the productivity and reduce the consumption of buffer solutions, simulated moving bed (SMB) technology has been employed to isolate LF and LP from whey protein concentrate [141]. In SMB chromatography, multiple fixed beds are connected into a circulation loop where the feed and elution points are switched periodically from one bed to another. This process can achieve ~ 50% enhancement in productivity and ~ 5 times reduction in buffer consumption compared to conventional chromatographic processes. The commercial application of SMB chromatography for whey protein fractions, however, has been constrained by the increased pressure drop resulting from the series arrangement of the fixed beds and the challenges in process modelling for designing the operational parameters in multicomponent systems.

Similarly, a single-step expanded bed adsorption process (illustrated in Fig. 9) packed with cation exchanger Fastline SP was optimized to successfully isolate LF from crude sweet whey, with a high purity (88.5%) and a reasonable recovery (77.1%), as well as a purification factor of greater than 500 [142]. The use of an expanded bed allows for the recovery of LF from unclarified feedstock in high throughput operation, which is favorable for industrial applications.

Illustration of the different stages in an expanded bed adsorption process. Reproduced with permission from [143]

The separation of ALA and BLG from whey by ion exchange chromatography has mainly been carried out using anion exchange resins (AEX). The adsorption of ALA and BLG on a series of commercially available strong anion exchangers has been described using sweet whey at pH 6.5 [144]. While both ALA and BLG carry a net negative charge, all resins showed strong affinity toward BLG. Only the Dianion HPA 75 resin, however, could achieve appreciable fractionation. The ALA/BLG ratio increased to 2.2 in the ALA-rich fraction (from 0.41 in sweet whey), while the purity in the BLG fraction, eluted using 2–5 wt% NaCl solutions, improved to a BLG/ALA ratio of 14 (from 2.4 in sweet whey). Recovery was 78% for ALA and 87% for BLG. Impurities in the ALA fraction were found to be mainly Igs, while BSA was found in both the ALA and BLG fractions. On an analytical scale, a Mono Q5/50 GL anion exchange column in a fast protein liquid chromatography system was demonstrated to recover 60.5% of BLG in a pure form from WPC80, making subsequent fractionation of ALA, BSA, and Igs by simple gel filtration possible [145]. IRA93 (a polystyrene anion exchanger) was also used to selectively adsorb ALA (up to 88.1%) and BLG (up to 90.7%) from whey at pH 7 through multistage treatment, generating a spent whey stream which was further processed by a negatively charged Amicon YM 100 membrane (100 kDa MWCO) to produce a protein fraction enriched in Igs [146]. A more recent pilot scale study showed that an ion exchange resin (Q Sepharose) can selectively adsorb BLG from a pre-purified WPC enriched in ALA (78% purity after acid precipitation and three steps of ultrafiltration), resulting in ALA in the holo form with a purity of 97.4% and a recovery of 80%( [147].

Cation exchangers can also be used for the fractionation of ALA and BLG, although this approach is less popular, as these proteins are negatively charged at the natural pH of whey. When whey was adjusted to pH 4 using 1 M sulfuric acid, a SP sepharose cation exchanger was able to capture all positively charged proteins [148]. By varying elution buffers, the bound proteins could be eluted as (i) WPI alone, (ii) an ALA fraction and a WPI fractionation depleted in ALA, and (iii) four fractions: ALA, WPI depleted in ALA, LP, and LF. The recovery of ALA in the second and third elution routes was greater than 90%. The recovery of BLG was almost complete but it co-eluted with a significant amount of BSA and IgG. Instead of selective elution, SP sepharose fast flow cation exchange has also been used to isolate BLG and ALA from reconstituted whey protein concentrate using an acetate buffer adjusted to pH 3.7 [149]. Based on the selective adsorption process, where the preferentially adsorbed BLG could be slowly displaced by ALA [150], the displaced BLG fraction leaving the column in a single stage process could be collected with a purity of 95%, containing almost 80% of the original BLG. The bound proteins, once eluted, however, had an ALA purity of less than 60% and a recovery of around 20%.

The combination of cation exchange and anion exchange chromatographic steps has also been investigated to achieve full fractionation of major whey proteins, although the overall recovery and purity of the proteins are relatively low, making commercial application challenging. For example, a preparative chromatographic process was used to separate the four major proteins from sweet whey [138]. BLG could first be separated from sweet whey at pH 5.8 using an anion exchange step (Q-sepharose), while IgG could be further recovered using a cation exchange step (SP-sepharose). LP and LF could also be recovered from rennet whey in the first step using a strong cation exchanger (sulfopropyl-Toyopearl) [151]. ALA and BLG were then subsequently separated from the effluent generated by the first step using a strong anion exchanger (quaternary aminoethyl-Toyopearl), where ALA was eluted using a NaCl solution with less than 0.13 M at pH 6.5, while BLG was eluted at pH 8.5 with a higher NaCl concentration.

Cryogels are an emerging chromatographic medium that are formed into a single monolith within the column and show promise for separation of dairy proteins. The monolith contains super-macropores to provide better passage of fluids of a colloidal nature, such as milk. A poly(2-hydroxyethyl methacrylate)-based anion exchange cryogel was used to isolate IgG from casein whey, achieving a purity of more than 95% and a recovery of up to 94% [152]. Similarly, cationic polyacrylamide (carboxy-PAAm) cryogels could be used to separate LF directly from raw milk, homogenized milk, skim milk, and acid whey, with a yield of over 85% and a purity of greater than 90% [153]. More recently, high-purity (98–99.8%) LP was isolated from bovine whey with high yield (92%) using a cation exchange composite cryogel embedded with macroporous cellulose beads [154]. This was achieved, however, over three elution steps using different buffers. It should be noted that the binding capacity of these cryogels is at least an order of magnitude lower than in commercial ion exchange resins (e.g. < 5 mg/mL cryogel resin vs. ~ 50 mg/mL SP Sepharose resin [155]), potentially limiting commercial applicability in their current form.

Affinity Chromatography

Affinity chromatography is a common method for separating charged or uncharged molecules depending on their affinity for a ligand that is covalently bonded to the support matrix, which is applicable to whey protein separation. Importantly, selective adsorption of individual proteins can be achieved by this technique by choosing a ligand that strongly interacts with and binds selectively to a specific protein. Other proteins, which do not recognize the ligand, can freely pass through the column. The bound protein molecules are then eluted by adjusting the buffer pH, increasing the ionic strength, introducing a metal chelator, or introducing a higher concentration of the ligand, to destabilize the protein–ligand interactions. Owing to its high specificity, affinity chromatography allows for isolation of a specific protein or a small group of proteins in only one single step with around 1000-fold purification (Fig. 4). The conventional definition of affinity chromatography is based on biorecognition of an organic molecule by an immobilized ligand through enzyme–substrate, enzyme-inhibitor, or antibody-antigen interactions. Affinity chromatography can also be seen as the ultimate extension of adsorption chromatography, where the timescales of desorption are very long [132].

Beaded agarose is the most commonly used matrix for affinity chromatography due to good chemical stability, microporosity, and low nonspecific interactions of this linear polysaccharide. Early research found that the agarose matrix is not rigid enough under high flow environments, and that it is only stable up to 40 °C between pH 4 and 9. Crosslinking of agarose has led to enhanced agarose gels with high chemical and thermal stability, such as Fast Flow Sepharose and Sepharose-CL (Pharmacia, Sweden). Although crosslinking reduces the number of free hydroxyl groups for ligand substitution, gel rigidity is improved, with tolerance toward high temperature (up to 120 °C) and a wide pH range (2–14). Other commercial media include cellulose-based beads (e.g., Cellufine media by Amicon, USA) and synthetic hydrophilic microporous polymer supports (e.g., Fractogel TSK by Merck, Germany, Trisacryl GF by IBF).

The binding capacity of current commercial affinity resins available in the market typically ranges from 10 to 60 mg protein/mL resin [156, 157]. The ligands immobilized to the matrices for whey protein fractionation range from inorganic ions to small organic compounds, hydrophobic molecules and antibodies, as summarized in Table 4. The remaining paragraphs in this subsection discuss the applications of these different ligands for whey protein fractionation, in the order of ALA, BLG, BSA, IgG, LF, and LP, from various sources including cheese whey, casein whey, WPC, acid whey, and bovine milk.

Affinity chromatography has been applied to whey proteins to isolate ALA from whey or skim milk by promoting ion chelation, peptide adsorption, and hydrophobic interactions. The surface of silica gel was modified with β-diketoamine groups, in which copper ions were further absorbed, allowing for coordination complexes to form with some donor groups in proteins, such as carboxylate, amine, and mercaptan. Under these conditions, ALA can be effectively purified from casein whey with 66% yield [158]. Similarly, using a Cu(II)-chelating sepharose fast flow column, ALA was isolated from WPC with a recovery of 80% and a very high purity of 90%. The copper ions, however, were found to leach into the ALA-rich fraction, although they could be mostly removed using a second uncharged chelating column (from 2.8 to 0.1 µg/mL) [159].

Other affinity ligands and resins have also been successfully applied to separate ALA from dairy streams. A hexapeptide ligand (WHWRKR), which was synthesized onto a modified TosoHaas AF Chelate 650 (TosaHaas, USA) resin with free amino groups, could recover ~ 48% of ALA from a WPI solution (5.55 g/L), with a purity of greater than 90% [160]. A hydrophobic Streamline Phenyl resin was also employed to separate ALA from skim milk, which was pre-treated with a high dose of EDTA (250 mM in 500 ml skim milk) to complex all calcium ions (Ca2+) [161]. This approach made use of the highly apolar surface of ALA, which is exposed in the absence of Ca2+, allowing for binding to the hydrophobic gel. Elution may then be achieved using a Tris(hydroxymethyl)aminomethane (Tris) buffer containing Ca2+ to restore the protein to its native state. This was demonstrated as a fast and efficient approach to recover ALA from casein whey with a purity of 79% [162].

Selective purification of BLG can also be achieved by affinity chromatography, as BLG has a unique ability to bind to small hydrophobic molecules such as retinol. This affinity can be used to selectively adsorb BLG onto an all-trans-retinal moiety immobilized on aminopropyl Celite beads (Celite Corp., USA) [163]). This was investigated on a pilot scale to successfully isolate BLG from sweet whey, where an increase in purity could be achieved by moving from a packed-bed column (80%) to a stirred tank and fluidized bed column (both > 95%) [164]. The low purity and recovery of BLG in the large-scale packed column was attributed to the improper distribution of the fluid across the full diameter and the tight packing of the modified Celite particles, leading to insufficient contact between the fluid and the immobilized all-trans-retinal moiety.

Other affinity chromatographic techniques have also been explored for BLG purification. Ceramic hydroxyapatite, a mineral form of calcium apatite (Ca5 (PO4)3), was found to recover up to 55% of BLG from acid whey with a purity of 96% [165]. It was noted that the adsorbed BLG was eluted together with traces of IgG, BSA, and LF. A size exclusion step (Superdex 75 column) could then be used to further improve the purity to appropriately 99%. Further, immunoaffinity chromatography has also been employed to study the adsorption of BLG B onto an anti-BLG immunochromatographic column based on the specific antigen–antibody interactions. The polyclonal antibodies, anti-bovine BLG (A + B), were immobilized on an aldehyde-silica support, which was prepared from epoxy-silica particles (Millpore, USA) [166].

Immunoaffinity chromatography can also be used for BSA isolation. For example, BSA was selectively bound to an NHS sepharose 4 fast flow resin, on which the binding domain fragment from llama antibody was immobilized [167]. In this case, BSA was desorbed from the column at pH 3, with almost 100% BSA recovered from cheese whey and a purity of at least 90%.

For IgG fractionation, a bacteria type III IgG Fc receptor, namely, protein G, has been demonstrated as a suitable ligand for selective IgG binding. Protein G sepharose 4 fast flow and native insoluble protein G were both used to isolate IgG from cheese whey. The purity obtained using Protein G Sepharose was much higher than native protein G (90% vs. 68%) [168]. Moreover, using a thiophilic gel (T-gel) can facilitate the thiophilic interactions between IgG and a sulfone group that is close to a thioether group of the ligand. A reasonably pure IgG fraction (74%) could also be obtained from sweet whey using T-gel, but this was slightly lower than the purity (81%) obtained by using protein G sepharose 4 fast flow [169].

Recent studies on LF purification focus mainly on heparin and dye affinity chromatography. Heparin, a negatively charged, highly sulfated and polydispersed linear polysaccharide has been widely used as an “all-purpose” ligand for purification of many biomolecules [168] including minor proteins in whey such as LF and other growth factors. The use of Heparin Sepharose could produce fractions of LF with greater than 95% purity from cheddar cheese whey with a 92% iron-binding capacity [168], comparable to immunoaffinity chromatography using immobilized monoclonal antibodies, which yielded LF fractions with a 97% purity from skim milk, with a 99% iron-binding capacity [170]. The isolation of LF from whey has also been studied using Yellow HE-4R dye as a low-cost ligand [171] as well as Cu2+ loaded polyacrylamide cryogel [172]. Both were claimed to produce high purity LF (> 90%). Only 80% of the adsorbed LF, however, was desorbed from the crosslinked chitosan mini-spheres immobilized with the Yellow HE-4R dye, and the LF yield was not reported for the cryogel experiments.

Dye-affinity chromatography has been investigated to purify LP from whey. Eighteen triazine dyes were immobilized on Sepharose 6B and screened as ligands for LP binding. The Reactive Red 4-Sepharose matrix showed the highest yield (86%), with a purity of greater than 80% and a purification factor of higher than 45 [173]. A higher purification factor could be achieved when sulfanilamide, an inhibitor of LP, was used as the ligand and immobilized to a cyanogen bromide (CNBr)-activated-sepharose 4B matrix with L-tyrosine as the spacer arm. In this case, LP was reported to be purified over 400-fold from bovine milk, with a yield of greater than 60% [174].

Heparin affinity chromatography can also be used to extract IgG, growth factors, and other minor whey proteins such as heart-type fatty acid-binding protein (H-FABP), transthyretin, b2-microglobulin, and angiogenin from WPI by ion exchange chromatography, involving separate recovery of ALA and BSA [175]. The integration of chromatographic techniques, set up in expanded beds, with ultrafiltration was used to successfully fractionate multiple proteins from crude sweet whey (Fig. 10) [176]. Higher-purity LF was isolated from whey in the first expanded bed packed with cation exchanger Fastline SP, as discussed earlier. The second bed was packed with a commercial resin, Stremline Direct CST-1, immobilized with a hydrophobic and cation exchange mixed mode ligand, and was able to recover more than 60% IgG with a purity of greater than 83%. The whey stream from the expanded adsorption beds after LF and IgG recoveries was subsequently processed by ultrafiltration (10 kDa MWCO) to produce a WPC stream. This process enables the full utilization of whey with two highly valuable minor proteins (i.e., LF and IgG) isolated with reasonable recovery and purity.

An example of integrated chromatographic processes used to isolate LF and LG from sweet whey (PBS, sodium phosphate buffer; BBS, sodium bicarbonate buffer). Reproduced with permission from [176]

Membrane Adsorber/Membrane Chromatography

Membrane adsorbers (MA) are thin, micro- or macro-porous layers that are functionalized with similar ligands to those used for resin-based chromatography [177], enabling them to preserve comparable resolution in separating molecules [178,179,180]. Numerous studies have reported that ion exchange membrane adsorbers can be used to fractionate proteins from whey, but limited information is available regarding the use of affinity membrane adsorbers for whey protein separation due to the highly expensive nature of affinity chromatography [181]. The fractionation of whey proteins using such ion exchange membrane adsorbers consists of two main steps in a similar manner to resin bed chromatography, namely, anion exchange followed by cation exchange. Anion exchange is first used to isolate ALA, BLG, and BSA [182,183,184]. The selectivity of both weak and strong AEX-MA toward BLG, BSA, and ALG is reported to be similar, showing a trend of binding strength as BLG > BSA > ALA [185]. Compared with the strong AEX-MA, the weak AEX-MA was saturated more rapidly resulting in a lower binding capacity. Initially, BLG, BSA, and ALA were adsorbed onto the membrane. After the membrane was saturated, BLG displaced ALA and BSA from the membrane, as BLG maintains its dimer form in the membrane phase and occupies double the number of adsorption sites compared with other proteins. A study also employed three commercially available AEX-MA to fractionate whey proteins [186]. The strong AEX-MA (i.e., Q15 and Q100) resulted in similar separation efficiencies. The strong AEX-MAQ15 was found to perform better compared with the weak D15 over a range of pH values 6.5–8.0. In the second step, CEX-MA can be used to isolate LF and LP from whey [184, 187]. Similar to CEX systems, the percentage of LP and LF eluted from the total bound protein is sensitive to salt concentration. Using 0.3 M NaCl, the average recovery of LP and LF from S-120 CEX-MA over 12 repeated cycles was 74 and 1.9%, respectively [187]. Using a higher concentration of 0.9 M NaCl, however, resulted in completely different results (2 and 50% of LP and LF recovery respectively) [187]. The 0.3 and 0.9 M NaCl elution peaks contained 2% LF and 2% LP, respectively, comparable to the impurities obtained with resin bed chromatography.

AEX-MA chromatography has been investigated with membrane filtration to separate BLG from a WPC stream prepared from raw casein whey [182]. As shown in Fig. 11, the casein whey was firstly clarified by centrifugation followed by MF. It was then concentrated using a UF membrane (5 kDa MWCO) to produce a WPC stream, which was further fractionated with 2 UF steps: a 30 kDa MWCO membrane to remove BSA, LF, and Ig and a 10 kDa MWCO membrane to produce a fraction containing ALA and BLG. An AEX-MA with quaternary ammonium ions immobilized on a regenerated cellulose acetate substrate (Vivapure™ Q Mini-H spin column) was applied in the last step to adsorb ALA, producing a final fraction enriched in BLG (87% purity with respect to total protein concentration).

Process flow diagram integrating membrane filtration and ion exchange membrane chromatography (IEMC) for BLG isolation from raw casein whey [182]

Compared with resin chromatography, MA chromatography can be operated at considerably faster flow rates with lower pressure drop [188]. This is because MA chromatography is mainly driven by convection, while resin chromatography is dominantly driven by diffusion, resulting in slower intraparticle diffusion that limits flow rates inside the column (Fig. 13). Molecules transport a long diffusion distance inside the resin bead (pore and film diffusion), whereas binding sites in a membrane adsorber are exposed to molecules within a relatively short distance (film diffusion). Conversely, MA have low binding capacity due to their lower surface area per unit volume [188]. For example, CEX-MAs showed a lower surface capacity for LF from whey (0.2 μg/cm2) compared with resin-based chromatography (1 μg/cm2) [184]. A cationic mixed matrix membrane (MMM) incorporating ion exchange resins was developed by Saufi et al. in order to improve this binding capacity [189]. The maximum static LF binding capacity of the MMM was around 3 mg/cm2. There was no data reported, however, for the dynamic binding capacity of MMM, which limits the interpretation, as this measure captures the effect of flow rates in real operation and normally results in a lower value [190, 191]. Similarly, Red HE-3B dye was immobilized in a polysulfone hollow fiber membrane, which had been grafted with a hydrophilic copolymer (glycidyl methacrylate/dimethyl acrylamide), to purify LF from bovine whey and colostrum [192]. The dye-affinity hollow fiber membrane adsorber could reach a maximum capacity of 111 mg LF/mL membrane, much higher than the 9.3 mg/mL obtained from the Sepharose 4B beads immobilized with Red HE-3B. The membrane adsorber took up 91% of the LF from a colostrum stream, 99% of which could be desorbed using 2 M NaCl in 25% ethylene glycol with a LF purity of 94%. Ethylene glycol (25%) has been used with phosphate or citrate buffers in order to effectively desorb BSA and LF from ion exchange membrane absorbers due to the ionic and hydrophobic interactions between the proteins and ion exchangers under these conditions [192, 193]. Such elution approaches should be avoided, however, or alternative molecules should be used, as ethylene glycol cannot be used in food production due to its high toxicity.

While low, the binding capacity of MAs is independent of flow rate (i.e., superficial velocity). In contrast, the binding capacity for column chromatography reduces significantly at high superficial velocities (i.e., low residence times) due to intraparticle diffusion limitations. Using BSA as a model protein, it was demonstrated by Boi et al. that the productivity of an anion exchange membrane adsorber was at least three times higher than the equivalent resin-packed column of identical volume and operating at equivalent superficial velocity due to such considerations [188].

Resin column chromatography units are difficult to scale up due to the complex molecular transport mechanism inside the resin beads which generates inconsistent pressure drops between large-scale and small-scale columns. The operational flow rate needs to be reduced to avoid issues with high pressure. As the feed streams in dairy processing are often viscous, an even lower flow rate is needed to operate with these streams [194, 195]. In contrast, membrane chromatography enables a better control of pressure drop. For example, two CEX-MA of different scales (Sartorius S100 (2 mL) and S120 (16 mL)) were shown to have a similar performance in fractionating LF and LP from sweet cheese whey in terms of recovery and purity [187]. More recently, a 50-fold scale-up of Sartobind membranes, from 3 to 150 mL, was demonstrated to effectively fractionate whey proteins [195]. A two-step approach was applied. The first step aimed to remove BLG and BSA by an AEX-MA (Sartobind Q). In the second step, the minor proteins (LF, LP, and IgG) were isolated by using a CEX-MA (Sartobind S), as ALA stayed in the serum phase. Both scales showed similar depletion of BLG (96%) and consistent purity and yield for ALA (Fig. 12). Except for LP, the purity for all proteins was close to or greater than 90%. The recovery for LF on the pilot scale (150 mL), however, was significantly lower than that on the lab scale (3 mL), which was attributed to the inhomogeneous adsorption of this protein.

Comparison of transport processes in resin bead and membrane adsorber. Reproduced with permission from [196]

Other Techniques

Liquid–liquid extraction using aqueous two-phase systems (ATPS) is a technique studied by some researchers for the isolation of ALA and BLG from cheddar cheese whey, bovine whey, and goat milk whey [197,198,199]. Polyethylene glycol (typically PEG 1500, 14–50 wt%) and potassium phosphate (18–30 wt%) at pH 7 were used in these studies to partition ALA in the top phase and BLG in the salt-rich bottom phase, resulting in a reasonable yield (up to 99% for BLG and 97% for ALA) and purity (up to 95% for BLG and 91% for ALA). Little work has reported, however, on the purification of the protein fractions from the two phases into saleable products. Although PEG is an approved additive in food processing by the FDA, the acceptable daily intake of PEG recommended by the WHO is less than 25 mg per kg body weight. Consequently, the elimination of PEG in the final whey proteins produced by liquid–liquid extraction needs to be demonstrated. In a recent study, González-Amado et al. showed that ATPS with PEG 1500 and ammonium sulfate at pH 4 can recover 80% of lactose in the bottom phase while precipitating 95% proteins (100% BSA and BLG and > 95% ALA)) from cheese whey [200]. It was not possible, however, to achieve complete fractionation of the proteins in the precipitate in this study.

Magnetic fishing is a relatively recent technique explored for whey protein purification, owing to the development of magnetic nanotechnology. The ion exchange groups and ligands discussed in the chromatography sections can be immobilized onto magnetic particles for protein binding. The magnetic nanoparticles bound with target proteins can be rapidly separated by magnetic decantation. The application of magnetic nanoparticles has mainly been focused on selective LF adsorption. Magnetic particles, prepared by incorporating ion exchange groups onto polyglutaraldehyde coatediron oxide crystals, have been used to adsorb LF from crude bovine whey [201, 202]. Similarly, monodispersed magnetic particles coupled with heparin were used as a magnetic affinity adsorbent to isolate LF from casein whey, achieving a maximum LF binding capacity of 164 mg/g [203]. Salt buffers (0.2–1.5 M NaCl) were used to elute the adsorbed LF from the magnetically separated particles but complete desorption was difficult to achieve, with purification factors only less than 30. Concanavalin A (Con A), a group of lectins, was recently bound onto ferroferric oxide (Fe3O4) magnetic nanoparticles to reach a maximum LF adsorption capacity of 59.2 mg/g [204]. Magnetite nanoparticles coated with citric acid and Cu2+ ions were also shown capable of isolating BLG from cheese whey, although only up to half of the bound proteins could be recovered from the protein loaded particles using 2 M NaCl [205]. Complete recovery of adsorbed proteins from magnetic particles would require further research to enable reuse. One recent success is the complete desorption of ALA and BLG from magnetic nanoparticles coated with carboxylate-terminated carbosilane dendrons, which were used to retain the major proteins from cheese whey [206]. The elution process, however, required the use of 0.4% sodium dodecyl sulfate (SDS) at 100 °C for 10 min, which is not ideal for maintaining the bioactivity and functionality of the eluted proteins. Further research is therefore needed to optimize this technique.

Conclusions and Future Prospects

The intrinsic value of whey proteins has been widely recognized owing to their functional, nutritional, and biological properties and has driven up the demand for these proteins in their isolate form as ingredients for food and pharmaceutical manufacturing. Environmental conditions such as pH, ionic strength, temperature, and the introduction of external agents can alter the charge, size, and solubility of whey proteins, allowing for selective separation of target proteins from the mixture using different techniques. To date, conventional resin-based chromatography and membrane filtration are the most commonly adopted techniques in large-scale dairy processing. Membrane processing is a cost-effective approach for producing high-quality whey protein fractions. Yet the purity of the target protein is often moderate due to the limited membrane selectivity between proteins of similar molecular size, unless this method is combined with other techniques such as precipitation and enzymatic treatment. Resin-based chromatographic techniques, particularly affinity chromatography, offer an effective approach to produce protein with very high purity. Nevertheless, the long cycle times, the consumption of a large volume of buffer solutions for protein elution, and the high costs of adsorbents lead to much higher capital investment and operating costs compared to membrane processes. These factors limit the broad uptake of chromatography systems in the dairy industry, making such technology only economically viable for the isolation of highly valuable whey proteins such as lactoferrin and lactoperoxidase.

Membrane adsorbers combine the selectivity offered by chromatography resins with the high throughput associated with filtration membranes. This technology has been demonstrated to provide high productivity and low pressure drop, and is easier to scale-up. Membrane adsorbers, however, have yet to be implemented in dairy processing at scale primarily due to their limited binding capacity. Similarly, liquid–liquid extraction and magnetic fishing techniques require further developmental work to demonstrate the feasibility of full recovery of fractionated proteins into edible and saleable protein ingredients without jeopardizing protein bioactivity and functionality.