Abstract

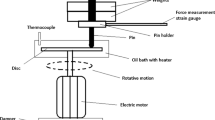

Considering the environmental problems created by mineral based lubricants, exploring the possibility of the use of vegetable base oils as automobile lubricants has been a growing worldwide trend. In the present study, analysis of coconut oil as a lubricant has been carried out in the perspective of its tribological behaviour using a pin-on-disc tribometer. Copper oxide nanoparticles are added to the oil on weight-percentage basis, the variation of its friction-reduction and antiwear properties are analysed. At an optimum concentration of nanoparticles, the coefficient of friction and the specific wear rate are found to be the lowest. Viscosity of oil is also seen to increase by an increase of concentration of nanoparticles. Flash-point remains constant while the fire-point increases as the nanoparticle concentration is increased. From dispersion analysis it is seen that the nano oil is not suitable enough for long stationary applications. Surface structure of the worn surfaces obtained by Atomic Force Microscopy (AFM) and Scanning Electron Microscopy (SEM) shows that the optimum concentration of nanoparticles in this lubricant causes the roughness of the worn pin surface to reduce to a low value after sliding. Wear scar obtained in the presence of nano oil is smoother compared to that with bare coconut oil. When the level of nanoparticles increases above the optimum level, friction coefficient and wear rate are seen to increase.

Similar content being viewed by others

References

Erhan, S. Z., Sharma, B. K., Liu, Z. and Adhvaryu, A., “Lubricant base stock potential of chemically modified vegetable oils,” J. Agric. Food Chem., Vol. 56, No. 19, pp. 8919–8925, 2008.

De Chiffre, L., “Function of cutting fluids in machining,” Lubrication Engineering, Vol. 44, No. 6, pp. 514–518, 1988.

Erhan, S. Z. and Asadaukas, S., “Lubricant basestocks from vegetable oils,” Industrial Crops and Products, Vol. 11, No. 2–3, pp. 277–282, 2000.

Ojolo, S. J., Amuda, M. O. H., Ogunmola, O. Y. and Ononiwu, C. U., “Experimental determination of the effect of some straight biological oils on cutting force during cylindrical turning,” Revista Matéria, Vol. 13, No. 4, pp. 650–663, 2008.

Fox, N. J. and Stachowiak, G. W., “Vegetable oil-based lubricants-A review of oxidation,” Tribology International, Vol. 40, No. 7, pp. 1035–1046, 2007.

Jagadeesh, K. M. and Satish, V. K., “Studies on boundary lubrication properties of oxidised coconut and soy bean oils,” Lubrication Science, Vol. 21, No. 9, pp. 355–365, 2009.

Dowson, D., “History of Tribology, 2nd ed.,” John Wiley & Sons, pp. 264–266, 1998.

Jayadas, N. H., Prabhakaran Nair, K. and Ajithkumar, G., “Tribological evaluation of coconut oil as an environment-friendly lubricant,” Tribology International, Vol. 40, No. 2, pp. 350–354, 2007.

Krzan, B. and Vizintin, J., “Tribological properties of environmentally adopted universal tractor transmission oil based on vegetable oil,” Tribology International, Vol. 36, No. 11, pp. 827–833, 2003.

Maleque, M. A., Masjuki, H. H. and Sapuan, S. M., “Vegetablebased biodegradable lubricating oil additives,” Industrial Lubrication and Tribology, Vol. 55, No. 3, pp. 137–143, 2003.

Jayadas, N. H. and Prabhakaran Nair, K., “Coconut oil as base oil for industrial lubricants-evaluation and modification of thermal, oxidative and low temperature properties,” Tribology International, Vol. 39, No. 9, pp. 873–878, 2006.

Yu, H., Xu, Y., Shi, P., Xu, B., Wang, X. and Liu, Q., “Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant,” Trans. Nonferrous Metals Society of China, Vol. 18, No. 3, pp. 636–641, 2008.

Zhou, J., Wu, Z., Zhang, Z., Liu, W. and Dang, H., “Study on an antiwear and extreme pressure additive of surface coated LaF3 nanoparticles in liquid paraffin,” Wear, Vol. 249, No. 5–6, pp. 333–337, 2001.

Hisakado, T., Tsukizoe, T. and Yoshikawa, H., “Lubrication mechanism of solid lubricants in oils,” Journal of Lubrication Technology, Vol. 105, No. 2, pp. 245–252, 1983.

Vamsi Krishna, P., Srikant, R. R. and Nageswara Rao, D., “Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 10, pp. 911–916, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thottackkad, M.V., Perikinalil, R.K. & Kumarapillai, P.N. Experimental evaluation on the tribological properties of coconut oil by the addition of CuO nanoparticles. Int. J. Precis. Eng. Manuf. 13, 111–116 (2012). https://doi.org/10.1007/s12541-012-0015-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0015-5