Abstract

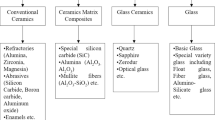

Industrial ceramics is one of the new materials that have advantages like high strength characteristics, wear-resistance, chemical stability and corrosion-resistance. In general, the production of high strength ceramic requires finishing processes because of the sintering processes, but the machining of ceramic is difficult due to its high strength and brittleness. If such disadvantages are complemented, the engineering ceramics will probably be applied in more diverse fields. Therefore, as a way to overcome such weaknesses, laser assisted machining that locally heats, softens and cuts materials was studied intensely by using laser beams as a heat source. In this paper, material changes by difference of a laser power and the structural changes of the material surface when it was heated by laser beam were observed. When the temperature increased, the Si and N which are comprised the silicon nitride decomposed and turned to gas, eventually erupting outside or forming porosity inside to induce micro-cracks. In addition, as YSiAlON, which surrounded β-Si3N4, softened at 1,000°C or above, cutting was enable due to plastic deformation. In particular, the surface of the specimen oxidized at a high temperature formed an amorphous silicate, and subsequently experienced deterioration of hardness compared to silicon nitride.

Similar content being viewed by others

References

Bocanegra-Bernal, M. and Matovic, B., “Dense and Near-Net-Shape Fabrication Si3N4 Ceramics,” Materials Science and Engineering: A, Vol. 500, No. 1, pp. 130–149, 2009.

Lei, S., Incropera, F. P., and Shin, Y. C., “Experimental Investigation of Thermo-Mechanical Characteristics in Laser-Assisted Machining of Silicon Nitride Ceramics,” Journal of Manufacturing Science and Engineering, Vol. 123, No. 4, pp. 639–646, 2001.

Rozzi, J. C., Incropera, F. P., Pfefferkorn, F. E., and Shin, Y. C., “Experimental Evaluation of the Laser Assisted Machining of Silicon Nitride Ceramics,” Journal of Manufacturing Science and Engineering, Vol. 122, No. 4, pp. 666–670, 2000.

Lei, S., Shin, Y. C., and Incropera, F. P., “Deformation Mechanisms and Constitutive Modeling for Silicon Nitride Undergoing Laser-Assisted Machining,” International Journal of Machine Tools and Manufacture, Vol. 40, No. 15, pp. 2213–2233, 2000.

Rebro, P. A., Incropera, F. P., and Shin, Y. C., “Laser-Assisted Machining of Reaction Sintered Mullite Ceramics,” Journal of Manufacturing Science and Engineering, Vol. 124, No. 4, pp. 875–885, 2002.

Ready, J. F., Farson, D. F., and Feeley, T., “LIA Handbook of Laser Materials Processing,” Laser Institute of America Orlando, pp. 181–183, 2001.

Kim, J. D., Lee, S. J., Lee, J. H., and Sano, Y., “A Study on the Microstructural, Thermal and Mechanical properties of Silicon Nitride Ceramic,” Journal of the Korean Society of Marine Engineering, Vol. 33, No. 7, pp. 1026–1033, 2009.

Kim, J. K., Lee, S. J., Suh, J., and Lee J. H., “A Study on Laser Assisted Machining for Silicon Nitride Ceramics (I) — Preheating Characteristics and Oxidation Behaviors of Silicon Nitride Ceramics with Machining Parameters,” Journal of KWJS, Vol. 28, No. 4, pp. 61–66, 2010.

Kim, J. D., Lee, S. J., Kang, T. Y., Suh, J., and Lee, J. H., “A Study on Laser Assisted Machining for Silicon Nitride Ceramics (II)- Surface Characteristics of LAM Machined SSN and HIPSN,” Journal of KWJS, Vol. 28, No. 5, pp. 80–85, 2010.

Kim, J. D., Lee, S. J., and Suh, J., “Characteristics of Laser Assisted Machining for Silicon Nitride Ceramic according to Machining Parameters,” Journal of Mechanical Science and Technology, Vol. 25, No. 4, pp. 995–1001, 2011.

Kim, J. D., Lee, S. J., and Suh, J., “Characteristics of Si3N4 Laser Assisted Machining according to the Laser Power and Feed Rate,” Journal of the Korean Society of Marine Engineering, Vol. 34, No. 7, pp. 963–970, 2010.

Kim, J., D., Lee, S. J., Kang, T. Y., Suh, J., and Lee, J. H., “A Study on Laser Assisted Machining for Silicon Nitride Ceramics (III) — Variation of the Main Cutting Force and Life of Cutting Tool by LAM of SSN and HIPSN,” Journal of KWJS, Vol. 28, No. 6, pp. 35–39, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, SJ., Kim, JD. & Suh, J. Microstructural variations and machining characteristics of silicon nitride ceramics from increasing the temperature in laser assisted machining. Int. J. Precis. Eng. Manuf. 15, 1269–1274 (2014). https://doi.org/10.1007/s12541-014-0466-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0466-y