Abstract

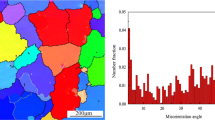

The isothermal compression tests of Al–5Ti–1B master alloy were conducted on the thermal mechanical simulator Gleeble-1500D at the deformation temperature range of 300–450 °C, the strain rate range of 0.01–10.00 s−1, and the engineering strain of 50 %. The effects of deformation temperatures and strain rates on the flow stress were analyzed by the true stress–true strain curves. The result indicates that the flow stress increases with the increase of strain rate, while it decreases with the increase of temperature. The hot deformation activation energy of Al–5Ti–1B master alloy is calculated to be 250.9 kJ·mol−1, and the constitutive equation is established as \(\dot{\varepsilon } = 1.97 \times 10^{19} \left[ {\sinh (0.015\sigma) } \right]^{11.14} \exp ({{ - 250.9} \mathord{\left/ {\vphantom {{ - 250.9} {RT}}} \right. \kern-0pt} {RT}})\), and the validity of this constitutive equation is verified. Based on dynamic material model (DMM) criterion, the hot processing map of Al–5Ti–1B master alloy is obtained. The optimum hot extrusion conditions are determined as deformation temperature of 400 °C and strain rate of 1.00 s−1, and the flow instability only appears at the temperature range of 300–340 °C at the base of the hot processing map.

Similar content being viewed by others

References

Qi WJ, Wang SC, Chen XM. Effective nucleation phase and grain refinement mechanism of Al-5Ti-1B master alloy. Chin J Rare Met. 2013;37(2):179.

Zhang BQ, Fang HS, Li JG. An investigation on microstructure and refining performances of newly developed Al-Ti-C grain refining master alloys. J Mater Sci Lett. 2000;19(16):1485.

Sigworth GK. The grain refining of aluminum and phase relationships in the Al-Ti-B system. Metall Trans A. 1984;15(2):277.

Kashyap KT, Chandrashekar T. Effects and mechanisms of grain refinement in aluminum alloys. Bull Mater Sci. 2001;24(4):345.

Sun SL, He WW, Zhang MG, Chai YS. Hot deformation mechanism of 9Cr-2W heat-resistant alloy. Chin J Rare Met. 2013;37(4):557.

Sharma MM, Amateau MF, Eden TJ. Aging response of Al-Zn-Mg-Cu spray formed alloys and their metal matrix composites. Mater Sci Eng. 2006;424(1–2):87.

Dunlavy MA, Shivpuri R, Seniatin SL. Failure during hot working of spray-formed Rene’88. Mater Sci Eng. 2003;235(1–2):210.

Wang MH, Huang L, Xian GC. Flow stress behavior of Cu-Ag alloy under hot compression deformation. Chin J Rare Met. 2013;37(5):695.

Du B, Li DF, Guo SL, Xie W. Hot compressive deformation behaviors of nickel base alloy Hastelloy C-276. Chin J Rare Met. 2013;37(2):215.

Zhang Y, Ge CC, Guo B, Shen WP. Hot deformation behavior of spray formed FGH4095. Acta Phys Sin. 2012;61(21):1.

Wang QJ, Liu F, Du ZZ, Wang JY. Hot-compression deformation behavior of Cu-Cr-Zr alloy. Chin J Rare Met. 2013;37(5):687.

Etaati A, Dehghani K, Ebrahimi GR, Wang H. Predicting the flow stress behavior of Ni-42.5Ti-3Cu during hot deformation using constitutive equations. Met Mater Int. 2013;19(1):5.

Li B, Pan QL, Zhang ZY, Zhou J. Research on the hot deformation behavior of Al-Zn-Mg-Sc-Zr alloy during compression at elevated temperature. J Mater Eng Perform. 2013;22(2):536.

Venugopal S, Mannan SL, Prasad YVRK. Processing map for cold and hot working of as-cast stainless steel type AISI 304. J Mater Sci Lett. 1993;12(23):1875.

Gegel HL, Malas JC, Doraivelu SM, Shende VA. Metals Handbook. Metals Park, Ohio: ASM; 1987. 417.

Somani MC, Bhagiradha ES, Birla NC, Bhatia ML, Prasad YVRK. Processing map for controlling microstructure in hot working of hot isostatically pressed powder metallurgy NIMONIC AP-1 superalloy. Metall Trans A. 1992;23(10):2849.

Ebrahimi GR, Momeni A, Abbasi SM, Monajatizadeh H. Constitutive analysis and processing map for hot working of a Ni-Cu alloy. Met Mater Int. 2013;19(1):11.

Jiang P, Fu WT, Wang ZH, Bai XH, Zhao XC, Lv ZQ. Hot deformation behavior of an 8% Cr cold roller steel. J Mater Sci. 2011;46(13):4654.

Zhang JQ, Di HS, Wang HT, Mao K, Ma TJ, Cao Y. Hot deformation behavior of Ti-15-3 titanium alloy: a study using processing maps, activation energy map, and Zener-Hollomon parameter map. J Mater Sci. 2012;47(9):4000.

Prasad YVRK, Seshacharyulu T. Modeling of hot deformation for microstructural control. Int Mater Rev. 1998;43(6):243.

Acknowledgments

This study was financially supported by the Natural Science Foundation of Heilongjiang Province (No. E201107)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, FW., Zhou, J., Wang, ZW. et al. Constitutive equation and hot processing maps of Al–5Ti–1B master alloy. Rare Met. 37, 668–674 (2018). https://doi.org/10.1007/s12598-014-0426-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0426-9